Whitepaper

Published: September 06, 2022

Making Building Electrification Real

Along with energy efficiency, next generation refrigerants, safer refrigerant management practices and various efficiency-focused building upgrades, the electrification of heating and cooling is essential for reducing the environmental impact of buildings. Discover re-imagined electrified solutions for your building project with the help of Trane.

Quick Facts

Using Trane’s new Ascend® Air-to-Water Heat Pump and Comprehensive Chiller-Heater Solution to Deliver Flexibility, High Performance and Reliability for a Broad Spectrum of Buildings.

The decarb movement is coming soon to a building near you. Are you ready to participate?

Along with energy efficiency, next generation refrigerants, safer refrigerant management practices and various efficiency-focused building upgrades, the electrification of heating and cooling is essential for reducing the environmental impact of buildings. As the nation’s energy grid transitions to greener, carbon-free and less emissive energy sources, policymakers and decision makers at all levels are now looking to concurrently reduce fossil fuel consumption in buildings while amplifying and accelerating the effect of cleaner power to reduce greenhouse gas emissions. We are on the cusp of a major transformation in building HVAC systems across the country.

Trane’s Comprehensive Chiller-Heater System is ideally suited to provide commercial buildings with reliable, cost-effective, energy efficient building comfort – without or with very little fossil fuels.

Electrification is the (near) future

Across the country, building electrification is gaining increased momentum as a practical strategy to decarbonize buildings. It’s effective and logical in places where the electric grid is transitioning to clean renewable energy sources. Most electricity generation today still draws from fossil fuels; however, the rapid growth of utility-scale and onsite renewables in the energy mix around the world is making decarbonization through electrification possible.1

It's a noteworthy accomplishment that, nationally, the electric power sector has reduced emissions more than 25%. On the other hand, there has been no real change in carbon emissions from direct fossil fuel use in homes and businesses in decades.2

Cooling (air conditioning) is already electric. The majority of emissions that come directly from building is traceable to the use of fossil fuels for heating systems.

Change is in the air. A burgeoning effort to remove direct fossil fuel use inside buildings is in full swing across the world and will soon impact main street building owners and influence companies’ ESG reporting. Many states and cities have instigated policies that incentivize electrification in North America: New York’s Climate Mobilization Act mandates buildings above 25,000 square feet to cut emissions by 40% by 2030. The state mandates an 80% reduction by 2050. Massachusetts’ 3-year energy efficiency plan includes incentives for strategic electrification, including incentive programs for fuel switching—targeting oil and propane customers for fuel conversion to air source heat pumps and other technologies. Minneapolis, MN, targets a 30% reduction in GHG emissions by 2025 and an 80% reduction by 2050. Its planned pathways to achieving GHG reductions from buildings include electrification.3

The pressure is on building owners, and it gets financial

More than 20 states have already set mandatory decarbonization targets to reduce their reliance on fossil fuels. To help drive reductions, many more entities are also establishing financial incentives for building electrification – in essence replacing fossil-fuel driven HVAC systems with electric alternatives such as heat pumps. They have to. Reducing CO2 emissions from buildings is necessary to meet these goals, as buildings account for 38% of global energy-related CO2 emissions and HVAC accounts for 40% of building energy use.4

So far 48 states have incentives in place for the use of heat pumps by buildings, and 13 have incentives for all-electric heating systems. Furthermore, many companies’ own sustainability goals – which 92% of S&P 500 companies have – include net-zero commitments that will likely necessitate carbon reduction measures and accelerate a transition to hybrid or all-electric HVAC systems.5 Forty-two percent of Fortune 500 companies have either an absolute or intensity-based emissions reduction target.6 Legislated change takes time. Social and financial pressures will likely motivate action sooner.

Whether out of conviction on the merits or compliance with changing regulations and financial incentives, building electrification will cause many building owners to look for guidance from consulting and specifying engineers.

Heat Pumps Have a Key Role to Play

So, why focus on heat pumps? Other forms of electric heating exist—such as resistance heating, which includes electric furnaces and baseboard heaters. Heat pump technology has bubbled up as the industry leader due to its lower energy consumption and, subsequently, lower operating cost and reduced impact on peak load demand. Furthermore, hydronic heat pump systems, the focus of this article, are proven performers that are readily available in North America. This is a rare example of how meaningful industry transformation can be based on a proven solution that already exists.

Some of your clients may be familiar with heat pump technology, if not in their commercial buildings, then in residential use. Most will need an explanation of its advantages, and you can keep it as simple as this: Heat pump solutions do not generate heat; they move heat from areas with excess heat to areas that need more heat. Due to the laws of thermodynamics, it takes less energy to transfer heat than to generate it, which results in significant energy and cost savings. Think of it as the “recycle & reuse” of a building’s heat energy.

Trane’s solution: A new Comprehensive Chiller-Heater System featuring the Ascend® Air-to-Water Heat Pump

Traditionally, heat pumps were seen as a residential heating and cooling solution, and rarely scaled to the sizes needed for larger buildings. And their use was limited to climates with outdoor temperatures greater than, say, 20°F. Below that temperature, second stage heat from either fossil fuel or electric resistance is activated. And even in temperate climates, heat pumps must periodically defrost. The same constraints that limit heat pumps in residential use in colder climates require the same considerations for commercial buildings—on a much bigger scale.

Trane’s new system provides commercial users with reliable, cost-effective, energy efficient options to cool and heat their facilities while reducing carbon emissions – without sacrificing occupant comfort. Our pre-engineered solutions make electrified HVAC easier to specify and implement while delivering the benefits building owners expect:

- Flexibility—to satisfy diverse heating and cooling loads and complying with electrification regulations and sustainability objectives.

- High performance—by exploiting significant improvements in heat pump heating to enable buildings to function better and reduce carbon emissions.

- Reliability—by managing equipment capabilities to reduce the impact of defrost on system performance and enabling cold climate operation.

- Lower cost of ownership—by reducing equipment and energy costs while increasing efficiency and reliability for building owners.

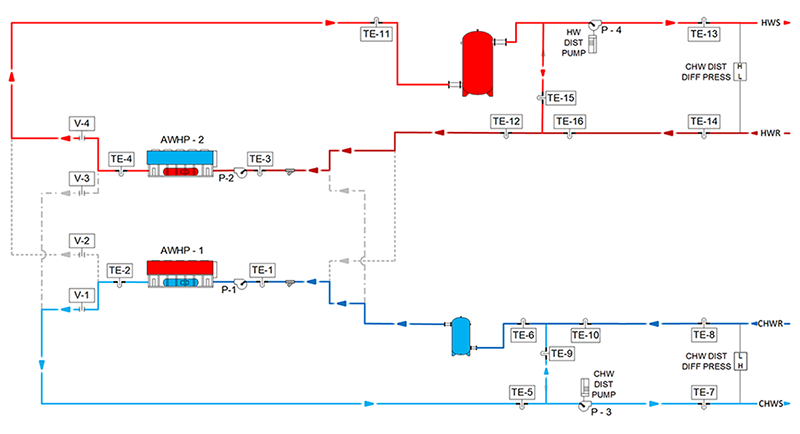

Comprehensive Chiller-Heater System Diagram

Ascend® Air-to-Water Heat Pump model ACX

At the center of the system is Trane’s new Ascend® Air-to-Water Heat Pump model ACX. The Ascend® ACX is available in six sizes ranging from 140 to 230 Tons of nominal cooling and 1500 to 2500 MBh heating capacity and complies with ANSI/ASHRAE/IES 90.1-2019. As we mentioned earlier, heat pumps move and increase the grade of heat rather than generate it, which means Ascend® model ACX can be up to three times more efficient than electric resistance heating.7 And, it brings Trane’s economical heat pump technology up to a scale that provides an energy-code-compliant electrification solution that can serve the needs of a broad spectrum of commercial buildings, including government facilities, commercial real estate, K-12 schools, hospitality and out-patient healthcare facilities.

Features include:

- Heating efficiency meets ASHRAE® 90.1-2019; 2.77 COP

- Cooling efficiency meets ASHRAE 90.1-2019; 9.215 EER

- Dual expansion valves – one for heating and one for cooling – for better system control and efficiency

- Cooling and heating efficiency meets building energy codes

- Variable speed fans, intermediate discharge valves on the compressor to optimize efficiency at all operating conditions

- Electronically commutated fan motors and brazed-plate evaporator for enhanced efficiency

- Common platform to the Ascend air-cooled chiller for simplicity of maintenance and availability of supplies

Flexible solution with options to meet your requirements

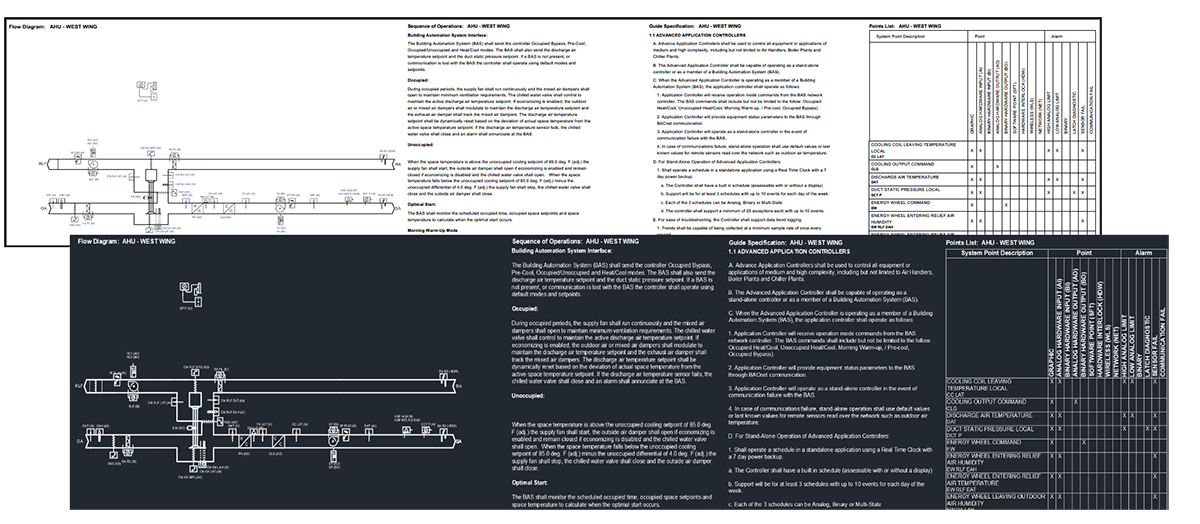

The Comprehensive Chiller-Heater Systems can also support a building’s IAQ objectives because it can be installed to fit with many existing hydronic air-side systems, including fan coils, air handlers and radiant systems. And these systems are supported by Trane with tools that make an electrified HVAC system easier to specify and implement

Ascend® ACX comes with many standard features and a wide range of options. Trane will provide the heat pump that meets your requirements for efficiency, cost and acoustics:

- Scroll compressor technology is affordable and practical, without compromising efficiency or sound

- Wide operating map meets load in extreme conditions

- Multiple sound packages to choose the level of acoustic performance desired

- Fin and tube coil reduces footprint

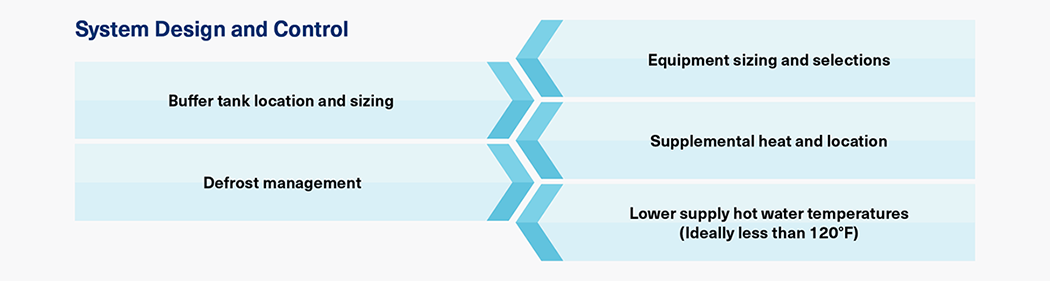

System design considerations

Some system design and control principles from chilled-water systems transfer well when applied to chiller-heater systems. But, there also are some important considerations that designers must consider regarding equipment sizing, buffer tank location, the need for supplemental heat in some climates and defrost management.

Reliability –The consequences of poor heating system performance are potentially more significant than a cooling system failure. Engineers need to factor into system design the potential for a 50-year weather event. Ascend® air-to-water heat pumps can deliver 140o F fluid temperature at 55o F outdoor air temperature (OAT) and are capable of heating down to 0oF while delivering 100o F fluid temperature.

Because air-to-water heat pumps have operating limits that become more restrictive as temperatures drop, engineers need to ensure they factor into their plans a redundant and reliable backup heating strategy to accommodate the potential for extremely low OAT. Comprehensive chiller-heater solutions can be optionally configured to allow for supplemental or dual-fuel heating when necessary, with more system configuration options such as dedicated heat recovery, free cooling and diurnal energy storage.

Flexibility – Heat pumps are designed to serve two systems with different expectations: cooling and heating. A cooling system for example may be designed for 10o F-12o F degree delta T while a traditional heating system might have been designed for a 20o F-30o F degree delta T. The system must be able to accommodate both needs. A Comprehensive Chiller-Heater System can be configured with two (or more) heat pumps – one for heating and one for cooling – with the proper system volume to match heating and cooling loads in real time.

Outdoor air temperature – Heat pump capacity and maximum supply fluid temperature are reduced as the OAT drops, and the system has outdoor air temperature operating limits. Equipment sizing is affected by these temperature conditions, the dual heating-cooling role and the availability of supplemental heat sources. It’s important to determine equipment sizing that fits temperature, flows and redundancy requirements to meet your year-round cooling and heating needs.

Defrost mode – An air-to-water heat pump will occasionally operate in defrost mode to ensure reliable heat exchange with ambient air. While the system is in defrost mode, heating from the hydronic system is interrupted. This interruption can be mitigated through equipment sizing, the use of a buffer tank and/or the use of a supplemental boiler. A proper mitigation strategy can minimize these disruptions.

Cold climates – A Comprehensive Chiller-Heater System featuring air-to-water heat pumps can also be configured for colder climates through the use of phase change energy storage and water-to-water heat pumps. The concept is to allow the air-to-water heat pump to only bring in supplemental energy into the building when the outdoor air conditions are suitable for operation, for better efficiency, and for better heating capacity. The energy brought in is stored in the phase change of water. Later, either when outdoor air conditions are unsuitable, energy prices are high, or when loads are higher, the water-to-water heat pump removes the stored energy and pumps it to a higher grade of heat for distribution. This system can be paired with other sources of low-grade heat such as solar thermal, wastewater systems, and airside energy recovery.

Another solution for cold climates is to use supplemental heat. This can take the form of fossil fuel-based boilers to be used only in extreme temperatures, auxiliary electric-hydronic heating in the form of an electric boiler, electric resistance heat in air-handling elements or electric radiant panels in the space.

Design support and expertise to simplify the task

Electrification brings new kinds of system components and system design requirements into the mix for consulting and specifying engineers. Trane has a full complement of resources to support design, equipment specification and selection to ensure a Comprehensive Chiller-Heater System featuring the Ascend® heat pump meets your application needs. Contact a Trane for more information.

Our Application Guide provides extensive information about system codes and standards, system and unit sizing, configuration and optional system components. We also offer system layouts and control sequences, and water-volume and carbon calculator tools.

There are also many system design and analysis tools from Trane to select the equipment you need on PC, tablet or smartphone, plus system design resources, system analysis tools and various calculators, including LEED compliance.

Commitment beyond the decision.

Any decision to decarbonize using a heat pump requires an ongoing commitment to maintain its benefits. Beyond the consultation and installation, professional providers must be available to optimize the system’s performance year after year. The consequences of heating system failure can be more significant than for cooling systems. Beyond the typical maintenance that’s required from a gas-heating system, heat pump systems must be prepared for extreme weather events. Not every service company has familiarity with heat pump technology and its unique requirements. Trane can provide all the expert services building owners will need to maintain the system’s ability to deliver consistent, reliable comfort and peak energy efficiency over time.

1 Source. Commercial building electrification market focus. Guidehouse Research

2 Source. Fossil Gas Has No Future in Low-Carbon Buildings. Rocky Mountain Institute)

3 Commercial building electrification market focus. Guidehouse Insights, Published 1Q, 2020

4 Alliance to Save Energy. “HVAC Efficiency: Why it Matters…"

5 U.S. Department of Energy. Quadrennial Technology Review, Chapter 5: Increasing Efficiency of Building Systems and Technologies

6 Calvert, CDP, Ceres, and WWF, Power Forward 3.0, How the Largest U.S. Companies Are Capturing Business Value While Addressing Climate Change, 2017.

7 Source: Trane Self-Paced Learning. Decarbonization/Electrification of HVAC Systems