- Customized myPLV value based on individual criteria.

- Reflects specific chiller installation location, building purpose, and chiller plant design.

- Modifications for faster operation with Excel 2010 and later.

Trane® myPLV®

Because every situation is unique, the myPLV® chiller performance evaluation tool offers a quick and simple option for chiller economic comparisons.

Overview

myPLV® chiller performance evaluation tool.

myPLV® is a vendor-agnostic tool that offers a quick and simple option for chiller economic comparisons, customized to reflect specific installation criteria and predict future performance.

-

Customized Chiller Evaluation

myPLV® calculates a customized value based on individual criteria, including installation location, building purpose, and chiller plant design.

-

Accurate Performance Prediction

The tool considers various factors to provide an accurate prediction of future chiller performance, aiding in better decision-making.

-

User-Friendly Resources

myPLV® includes resources like FAQs and a Getting Started Guide to help users quickly understand and utilize the tool.

Product Information

- Customized Evaluation: Calculates a customized myPLV value based on specific criteria.

- Performance Prediction: Accurately predicts future chiller performance considering various factors.

- Energy Simulation Tool: New tool to gauge annualized effects of design condenser water flow conditions.

- Excel Compatibility: Compatible with Excel 2010 and later for faster operation.

- User Resources: Includes FAQs and a Getting Started Guide for quick understanding.

myPLV Evaluation

Software Support Lifecycle

Beginning in 2023, new extended renewal subscription options will be available for the TRACE 700 family of products and Trane Design Tools. Learn more about your software End of Service and Support options.

Full Version

-

The latest version (3.2) of myPLV is available for use with Excel 2010 and later

-

Compatible with Excel 2007 or earlier

Getting Started

How to get started with myPLV Design Tool.

myPLV® is a chilled water system annualized energy modeling tool. It uses a bin analysis methodology that is customized for the building type, an 8760 hour building load profile as well as location specific 8760 hour weather data. The use of job specific customized bin data provides an accurate comparative basis for different types and efficiency chillers. This is something that the standard chiller only Integrated Part Load Value (IPLV) rating cannot and is not intended to provide. The job specific bin operating points produced by myPLV also provide excellent performance verification points for use in the bid, submittal and factory performance testing process.

See the FAQs below for more information on IPLV and its limitations.

A project specific whole building analysis conducted by an experienced modeler is the best method for evaluating chiller plant options, however this level of analysis may not be planned or budgeted for all projects. This tool can be used as a simplified alternative to a building model analysis for evaluating chiller energy usage considering rudimentary aspects of the plant design, location, and operation.

This tool has 3 main purposes:

1. Condenser Water Design Flow Optimization (New). This worksheet assists the designer in determining the optimal condenser flow for the specific system in question based on a customers needs. Numerous, peer reviewed, industry publications as well as other industry experts recommend designing condenser water systems with lower flows, (aka higher full load design Delta Ts), to optimize system power. These recommendations range from 12°F to 18°F depending on the system and chiller type. This worksheet can help zero-in on the optimal flow and Delta T for a specific project at the crucial time when chillers are being selected. For further reading on this topic we suggest the ASHRAE GreenGuide (available for purchase), ASHRAE 50% Advanced Energy Design Guides (free to download) and CoolTools™ Chilled Water Plant Design Guide (archive free to download from Taylor Engineering).

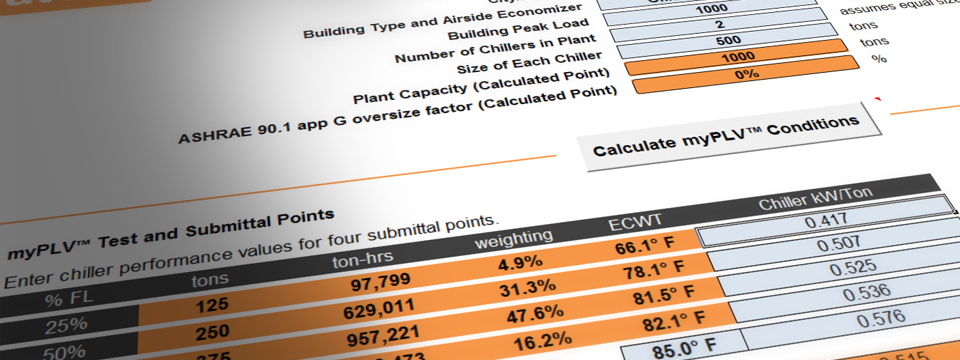

2. myPLV Calculator. Develops four chiller operating points that are then integrated into an application specific metric called myPLV which can be used as a means to predict chiller energy consumption specific to job location and application. The myPLV metric has a format similar to IPLV but is generated for a given project by using the criteria specified by the user in combination with load profiles from industry standard building models.

3. myPLV Bid Form. Provides a worksheet using the four myPLV submittal points and their calculated weighting to enable a quick and simple energy economic comparison between chiller performance alternatives. Because the economic impact of peak demand charges are also considered, the design operating point of the chiller(s) is also required for this analysis.

For detailed explanation of the inputs and calculation methodology scroll down to the “Assumptions and Explanations” section of this document or see the FAQ worksheet.

The following are the basic steps for using the myPLV® tool. The user is encouraged to “click around” and experiment with the worksheets’ operation.

- Open the myPLV application and save as a new file name for the specific job.

- Determine the desired Condenser Water Design Flow.

- On the “Cond Water Flow Optimization” worksheet enter:

- Location data

- Chiller plant and chiller sizing information

- Tower / condenser water base data.

- Cost assumptions for anciallary equipment

- Press the “Run Flow Optimizer” button.

- Examine the system "Annualized kW/ton Performance trends" and energy and costs savings data. Note, there are three scenarios to examine based on a customers requirements. Those are Energy optimized. This is the scenario where no equipment is downsized except the condenser pumps and will yield the highest energy savings, but the lowest first cost savings. The next is a lowest first cost scenario. This will yield the highest first cost savings and the lowest energy savings by reducing the size of the cooling towers, pumps, and the condenser piping. The last scenario is a balanced approach. This is a combination of the other two approaches. The cooling towers and pumps are reduced in size to save capital cost, but the condenser pipes are assumed to be the same size at each varying flowrate. By keeping the pipes the same size, the pressure drop and pump energy in the system is reduced significantly.

- Select the radio button under the desired system Condenser flow (gpm/ton). The input data for that selection will be transferred to the other calculation worksheets.

- On the “Cond Water Flow Optimization” worksheet enter:

- Select the “myPLV Calculator” worksheet. If the “Condenser Water Design Flow” worksheet was used the input data for this sheet should be pre-entered. If not the user will have to enter the building, chilled water system and tower design information.

- Press the “Calculate myPLV Conditions” button.

- Press the “Calculate myPLV Conditions” button.

- Select the “myPLV Bid Form” worksheet.

- Enter the electrical utility rates - $/kWh for consumption and $/kW and Ratchet Rate for demand

- Press the “Save and Send” button. This creates a copy of the myPLV Bid Form worksheet that can be sent to all qualified chiller vendors to fill out with base and alternate chiller performance and cost data for submittal back to the design engineer.

- When data is returned from all vendors it can be combined on the master sheet for analysis.

- The chiller load and ECWT points can be included in the chiller factory test schedule to create “myTEST” points for chiller test approval.

- Select the “myPLV Charts” worksheet tab.

- Evaluate the various charts to understand the modeled chiller performance as desired.

The myPLV tool is fast so the designer can perform various “What If” analyses for different plant and chiller design concepts.

Building Load and Weather Profiles

The building load profiles included in this program were generated from the public domain EnergyPlusTM files developed by Pacific Northwest National Labs (PNNL) for energy analysis work in conjunction with and with oversight from ASHRAE, for the development of ASHRAE/IES 90.1-2010 Energy Standard for Buildings Except Low-Rise Residential Buildings. The web site for the PNNL files can be found at https://www.energycodes.gov/development/commercial/prototype_models. PNNL used the EnergyPlus simulation program for various building types in the seventeen different ASHRAE Standard 169 climate zones.

For purposes of the myPLV analysis, all chiller loads in the building profiles of less than 1% max plant capacity have been set to zero. This is due to an issue in some of the PNNL simulations that resulted in a large number of run hours for central chiller plants at extremely low loads. Typically these loads were composed of pump heat, when normal building and/or chiller controls are expected to inhibit chiller plant operation. Deleting these very low loads results in a more typical run time for the chiller plant, as validated by comparing the modeled to actual building profiles. It is important to note that the user entry for "City" is provided for the user’s convenience to look up the appropriate climate zone. The PNNL models use the most representative weather data to represent the entire climate zone, so that the building load profile can be generalized to the entire zone and limit the scope to a reasonable number of simulations. In addition, the building load profile is scaled to the Building Peak Load entry as specified by the user on myPLV® worksheet. The four performance points listed on the myPLV worksheet as the “myPLV Test and Submittal Points” are developed by grouping the load data into (4) chiller plant load ranges - 0 to 37.5%, 37.5 to 62.5%, 62.5 to 87.5%, and 87.5 to 100%. These groupings are the bins where the center weighted test points are 25%, 50%, 75%, and 94%. Note that the 100% design point is not included in the performance weighting criteria since the top most bin of the 94% grouping includes the performance at the 100% load point.

However, the 100% design point is required in the submittal entry with the user specifying the entering condenser temperature. It is critical to specify this point since the chiller is selected to provide operation at this design point and meet the energy codes. Certified performance at this point is also critical for confidently sizing the electrical wiring, circuit ampacity, breakers and other protection devices, power factor correction, starters, controls, safeties, filling out the nameplate on the equipment, as well as for complying with UL and other agency listings and codes.

Tower Control Method Selections (water-cooled only)

The myPLV tool develops four submittal points for the evaluated chillers. For water cooled chillers, each submittal point is specified as a % load at an entering condenser water temperature (ECWT). The myPLV tool uses the cooling tower design condition performance and tower control method to determine the hour by hour ECWT for the chillers in order to ultimately calculate a ton-hour weighted ECWT for each submittal point.

Note: All calculations assume that a tower cell is sequenced with each chiller. Chillers are allowed to operate up to 100% of their design capacity before an additional chiller is enabled.

Tower Control Method Selections:

Full Tower Fan Flow - This selection will determine the entering condenser water temperature that results from the cooling tower running at full fan speed at all conditions unless the resulting entering condenser water temperature is less than the minimum specified by the user. If full fan power results in a temperature less than the minimum value specified, the entering condenser water temperature will be set to the minimum value specified. The tower performance is assumed to have a tower approach (Tleaving - Tambient wb) that is equal to the user entry for the cell labeled Tower Full Load Design Performance - Tower Wet-Bulb Approach (F). This tower approach linearly degrades to zero at no heat rejection (0 chiller plant load). The tower approach also changes with the outdoor wet-bulb temperature as the heat capacity of the moist air stream changes with ambient wet bulb conditions.

Fixed Temperature - This selection is typical of many installations that run the cooling towers to a constant temperature set point. This selection requires a temperature set point entry by the user. The computations assume this temperature set point value will be the entering condenser water temperature for the chillers unless the tower capacity at the specific conditions encountered cannot achieve the set point temperature. In this case the leaving cooling tower temperature will be equal to a value at full tower fan flow conditions.

Fixed Tower Approach - This selection will compute an entering condenser water temperature equal to the outdoor wet-bulb temperature value plus the tower approach entered by the user. If the cooling tower cannot achieve this temperature value, the temperature will be returned as that achieved by the full tower fan flow condition. If this method would result in a temperature value less than the minimum condenser water temperature specified, the minimum temperature set point value will be used.

Chiller Tower Optimization - This selection simulates the behavior of Trane’s Chiller Tower Optimization control strategy which results in a dynamically changing entering condenser water temperature set point as a function of chiller loading and ambient wet-bulb temperature. If the cooling tower cannot achieve the target set point value, the full tower fan flow leaving water temperature will be returned. If this method would result in a temperature value less than the minimum condenser water temperature specified, the minimum temperature set point value will be used.

The myPLV® tool has a new worksheet that provides energy impact calculation and trend charting to illustrate the benefits of optimized heat rejection system flow for water-cooled plant at specified operating conditions. The Condenser Water Design Flow Optimization worksheet contains a water-cooled plant simulation engine allowing the user to do “What Ifs” on energy conservation measures. As of this time this worksheet only works with “IP” units of measure. This simple to use annualized simulation tool for user defined job specific water-cooled plants and its display of component energy use trend data provides the designer with the information enabling the choice, design and specification of higher efficiency chilled water systems.

Many of the user inputs on Condenser Water Design Flow Optimization worksheet are repeated and shared with the myPLV Calculator (weather location, plant sizing, tower control). Beyond this basic system data, additional entries are required for the flow optimization simulation engine and can be modified within the selection range for “What if” analysis:

- Chiller type: “Fixed Speed” or “Variable Speed”. The code uses a representative performance model for centrifugal chillers

- A dataset describing tower performance at a 3 gpm/ton flow condition (design wet bulb, tower approach, condenser water pressure drop)

- Chilled Water temperature setpoint (range 36 to 55ºF)

- Chiller Design Efficiency at standard AHRI conditions (range 0.45 to 0.8 kW/ton)

- Tower Performance CTI Rating (range 30 to 100 gpm/hp)

- Cost assumptions for energy and anciallary equipment

Notes:

- The condenser water pump/motor combined efficiency is assumed to be 70% and the fixed pressure drop for the tower static lift is assumed to be 15 ft H2O. The program assumes the piping that is sized for 3 gpm/ton is retained at the lower design flow values. The condenser water pressure drop of the other flow elements, including the chiller, are assumed to reduce appropriately as the nominal design flow rate is reduced. Since the pressure drop is output in the results, the user can determine whether this pressure drop corresponds with their own hydronic system estimates.

- For the cooling tower, a CTI rating is used to determine the tower fan power at the tower design conditions. A variable speed tower fan is assumed and the computations use a combined motor and inverter efficiency of 90%. It is assumed the tower size remains fixed for the condenser flow rates at 0.25 gpm/ton intervals. It is assumed the manufacturer will make the appropriate tower nozzle or flow distribution modifications for each new design flow condition to optimize the selection.

- A radio button just underneath the gpm/ton value in the chart data is used to select new chiller and tower design data for use in the myPLV calculator worksheet. The design data is automatically copied to the myPLV calculator based on the radio button selected.

- This program does not include a chilled water pumping power analysis. Its focus is on the chiller and the heat rejection system and it assumes the same chilled water distribution system for all alternatives.

Here’s what to expect …

- Chilled water plants will show the ability to run at good annualized values. Play around with the tower control scheme to get a feel for those control methods that seem to offer the best overall performance opportunity. The advantage of optimizing condenser water design flow will be evident regardless of tower control methods.

- The amount of advantage is strongly influenced by the number of chillers in the plant as well as the condenser water system pressure drop.

- With today’s chiller, pump and fan efficiencies you will find that 2 gpm/ton condenser water flow (158F Delta T) serves as a good rule of thumb to maximize system efficiency.

- The detailed output will show the energy impact and design point shifts for the chiller, condenser pump, and the cooling tower with varying condenser flow. The user will need to evaluate their particular design to ensure similar behavior for tower approach and condenser water pressure drop.

Since the condenser water flow rate affects the chiller selection process, we anticipate the user will run this worksheet first. After deciding on a condenser water flow rate, the chiller and tower design conditions are copied to the myPLV Calculator. The myPLV calculator is then run to develop the myPLV Test and Submittal points with the relevant conditions moved to the myPLV Bid Form. The myPLV Calculator and bid forms have been modified to include the chilled water design point temperature and the condenser water design flow rate so the data is available for the submittal process.

Version 3.2 - Condenser Water Design Flow Optimization

©2020 - This material is proprietary to and copyrighted by Trane U.S. Inc. All usage of this material is limited to uses for the direct or indirect benefit of Trane U.S. Inc. Any other uses are not allowed under penalty of law unless approved in advance by an authorized representative of Trane U.S. Inc.

User Competency, Expertise and Proficiency is Assumed

The accuracy and/or efficiency of The Material is highly dependent on user-supplied data and actions. User's competency, expertise and/or proficiency to use The Material is assumed, otherwise User should request training and assistance, as available, from Trane prior to use of The Material. It is the User's responsibility to understand how User's decisions, data, and actions affect The Material including its use and output, and to understand that any input and/or calculation mechanisms in The Material are to be used only as a guideline for using The Material. The Material is meant to aid the User: The Material is not a subsitute for competency, design services, judgment, or experience. Design of the HVAC system is the prerogative and responsibility of the engineering professional using The Material.

FAQs

Your frequently asked questions about the myPLV Design Tool, answered.

This release provides:

- Modified programming to improve performance associated with the Excel 2013 release

- A new worksheet is added for exploring system performance when varying condenser water design flow rate (see the next 2 questions and the relevant section in the "Getting Started" tab)

The Integrated Part Load Value (IPLV) is a performance metric developed by AHRI as a means by which chiller efficiency may be rated based on the weighted average of four load points, each at a prescribed condenser temperature. According to AHRI 550/590 Appendix D, the IPLV value was not intended to be used to predict the annualized energy consumption of a chiller in any specific application or set of operating conditions. This is because the operational points and respective weightings which make up the IPLV method do not represent an individual chiller plant design, location, or operation and therefore will not provide reliable data to estimate chiller energy consumption. See the December 2009 ASHRAE Journal Article “A Closer Look at Chiller Ratings” for a more complete discussion of IPLV and it use.

You must first select a Region and a Country from the drop down menus. The appropriate weather zone map for that location will then be displayed.

Changing the UOM (Unit of Measure) converts all user inputs on the myPLV Calculator tab to the new unit of measure, and changes all labels and references depicting a unit of measure to the appropriate convention. Cooling capacity is listed in either Tons or kW; temperatures are listed in either °F or °C; and efficiency is listed as kW/Ton or kW/kW, depending on UOM selected.

Note: User entered load and weather data on the "Custom Load" tab is not converted in this manner as this could result in user entered data being overwritten unintentionally.

If checked, the checkbox next to the "Region" drop-down list will expose the "Custom Load" tab allowing users to enter custom building load and weather data for 8760 hours comprising one calendar year.

Note: When the building load and weather data are calculated by this tool for a selected location in the myPLV® calculator worksheet, the data is copied to the "Custom Load" tab both for reference and as a starting point for user provided custom load and weather data.

This occurs to force the user to re-calculate, ensuring that correct outputs for the input values are shown.

The user entry for City is used to map to the appropriate climatic zones (see the ClimateZones tab). The building load is generalized to that climatic zone rather than to the specific city. Load profiles are output from the Energy Plus simulation program created by Pacific Northwest National Labs (PNNL) for use in justifying the new ASHRAE Standard 90.1 (2010) efficiency levels and represent various building types in 20 climatic zones per ASHRAE Standard 169-2013.

Select a city from the list that is in the same climatic zone. To identify the correct zone, first locate your location on the blue climate zone map tab which is shown based on the country selected. Then in the "Region" drop-down box, select "By Climate Zone". This action will change the "Country" drop-down box to "Climate Zone", allowing you to select the desired climate zone from the list.

If your specific building is not on the list, choose a building type with characteristics and an operating schedule similar to your building. The load profiles are partly based on occupancy assumptions within the EnergyPlusTMmodels and details can be found on the “energy codes” website (a link is given in this FAQ section). The occupancy for various building types may be generalized as follows:

- Office – 12 hour operation; 5 days a week

- Hospital – 24 hour operation; 7 days a week; heavier occupancy during the day

- High Rise Apts – 24 hour operation; 7 days a week; lighter occupancy during the day

- Primary School – 12 hour operation; 5 days a week; seasonal

- Secondary School – 12 hour operation; 5 days a week; seasonal

- Hotel – 24 hour operation; 7 days a week

The building load profiles included in the myPLV® tool are generated from the public domain EnergyPlus files. These files were developed by Pacific Northwest National Labs (PNNL) for energy analysis work in conjunction with and with oversight from ASHRAE for the development of ASHRAE/IES 90.1-2010 Energy Standard for Buildings Except Low-Rise Residential Buildings. The web site for the PNNL files can be found at http://www.energycodes.gov/development/commercial/90.1_models.

The simulation in the condenser water flow optimization worksheet assumes the user typically selects chillers for use at 3 gpm/ton condenser water flow. In order to perform an energy comparison, the 3 gpm/ton condition is used as a starting point and the tower performance is entered as typical for your location. Note the first two lines are not user entered data (orange cells) – they are informational only and describe the wet bulb conditions for the user selected reference city supplying the TMY zone data. Note that the chiller entering condenser water design temperature is critical to the chiller selection and the tower performance and control must be able to supply a condenser water temperature that does not cause the chiller operating problems.

Example data set for the “Tower Selection Conditions at 3 gpm/ton”.

The simulation in the condenser water flow optimization worksheet assumes the user typically selects chillers for use at 3 gpm/ton condenser water flow. In order to perform an energy comparison, the 3 gpm/ton condition is used as a starting point and the tower performance is entered as typical for your location. Note the first two lines are not user entered data (orange cells) – they are informational only and describe the wet bulb conditions for the user selected reference city supplying the TMY zone data. Note that the chiller entering condenser water design temperature is critical to the chiller selection and the tower performance and control must be able to supply a condenser water temperature that does not cause the chiller operating problems.

Example data set for the “Tower Selection Conditions at 3 gpm/ton”

Data Point Label

| Value | Explanation |

Design wet bulb for Weather zone data, 0.4% humidity | 78.1 F | This data is auto selected and is only used as informational display. It is the 0.4% ASHRAE wet bulb value for the reference city of the selected zone

|

Maximum wet bulb for weather zone data | 81.8 F | This data is auto selected and is only used as informational display. This data point is the observed maximum wet bulb in the TMY data set for the selected zone.

|

Enter the design wet bulb for the cooling tower selection associated with 3 gpm/ton operation

| 78 F | User entered data point. A typical entry might be 78F, however it needs to represent your location! |

Tower design approach | 7F | User entered data point. A typical value is a 7F degree approach.

|

Chiller Design Entering Condenser water temperature | 85F | User entered data point. Often times this is just the design wet bulb added to the design approach (rows 3 and 4). But it can be higher if the user wants to add in a bit of design margin after reflecting on the maximum encountered wet bulb (row 2).

|

Condenser pump design pressure rise | 80 ft H2O | User entered data point. This is the pump pressure rise that would be expected when the entire plant is operating at design loads. The energy simulation assumes that some of the pressure drop components in the hydronic system will significantly reduce when the plant operates at lower flow rates. |

The standard rating conditions for AHRI water-cooled product are 44F leaving chilled water temperature, a 2.4 gpm/ton evaporator water flow, 85F entering condenser water temperature, and a 3 gpm/ton condenser water flow. Based on the user entered chiller performance (kW/ton) at these conditions the program will estimate the expected same chiller design performance at each new selection condition for each flow. This revised efficiency is displayed on the condenser water flow optimization table.

The myPLV® tool uses the EnergyPlusTM load profiles created by PNNL. The PNNL load profiles provide the tonnage for each of the 8,760 hours per year. The myPLV tool places each load value into the proper bin and sums up the total ton-hrs for each bin range. The total ton-hrs is the sum of the ton-hrs for all (4) bins.

The percent weighting is determined from the ton-hrs in each bin. The calculation is as follows:

[ton-hrs within that bin] x 100% / [total annual ton-hrs]

Water-cooled solution: For every hour there is a load and a corresponding entering condenser water temperature that is calculated based on the coincident wet bulb and the tower approach at that hour as computed by the cooling tower control method selected. Each entering condenser temperature is weighted by that hour's load value and summed with other weighted temperatures within that bin. This overall sum is divided by the ton-hrs for that bin to get an overall weighted entering condenser water temperature.

Air-cooled solution: The methodology is similar to the water-cooled solution; however, the outdoor ambient dry-bulb temperature is used directly as the entering condenser temperature since cooling tower performance need not be taken into account.

Water-cooled kW/ton: myPLV is calculated in the same fashion as IPLV:

myPLV = 1/[a/A + b/B + c/C + d/D]

...where the lower case letters are the decimal values for weighting, and the upper case letters are the chiller kw/ton for that bin at the myPLVTM conditions.

Air-cooled EER: myPLV EER is calculated in the same fashion as IPLV:

myPLV EER = a*A + b*B + c*C + d*D

Water-cooled: The ton-hrs value in each bin is multiplied by its respective kW/ton performance and the (4) bins are summed together.

Air-cooled: The ton-hrs value in each bin is multiplied by 12 and divided by respective EER value, then the (4) bins are summed together.

The annual kW-hrs can be used on the Bid Form tab to determine the operating costs of different chiller options. These electrical operating costs include both the demand ($/kW) and the energy consumption ($/kWh).

Ratchet rate is a term to describe minimum demand charges imposed by a utility company against peak power usage. For example, your building hit a peak power use of 500 kW in August and you have a ratchet rate of 50%, you will be charged at minimum for a 250 kW demand every month. Therefore, if your peak power use in January was only 100 kW, you would still be charge for a demand of 250 kW. A ratchet rate is common with many utility companies.

Simple payback is calculated by taking the price difference of an Option compared to the Base and then dividing that by the savings delta for Total Annual Energy Charge.

This application requires linkage to various system libraries. In order to resolve these references, the application macros must be allowed to run in the background and excel must be set up properly to let this happen. Enabling macros at program start is not sufficient, the trust center in Microsoft Excel must be set up to accommodate program execution of these macros. To do this for Excel 2010 and 2013 …

Start excel and select the “File” drop down menu

Select “options” and then select “Trust Center”

Press the “Trust Center Selections…” button

Select the “Macro Settings” from the selection list

The following 2 checkboxes need to be set:

- Enable all macros

- Trust access to the VBA project object model

Press OK and exit Excel

You can now run the myPLV application.