VO: You are listening to Cool Air Hot Takes.

Charles Jelen: Welcome to Cool Air Hot Takes the podcast that's as smart as your building's Thermostat twice as fun. I'm Charlie Gellan.

Dan Gentry: And I'm Dan. Every couple weeks we get together to bring you guys the latest news in HVAC. The. Of course some hot takes and

Charles Jelen: expert interviews with industry leaders. And this week we've got Zach Sense, he's the technician productivity manager here at Trane.

We're gonna talk about all things HVAC technicians, what's grinding their gears, what's the future look like and what challenges does the industry face?

Dan Gentry: And later on we'll have some HVAC headlines. We're gonna do an application engineer fantasy football. So stay tuned for that and we'll wrap it up with the stat of the day.

Charles Jelen: Alright, I have been very dere elect in my duties for season two. Yeah. You know, it's, it's not just Dan and I that are getting these guests to come on. We have people from all over the country, all over the company that are helping us find these guests and getting 'em connected with us, and I have been forgetting to thank them.

So we gotta run back through a little bit here. First off, thank you to Erica Gallant and Trevor Jolson for getting us hooked up with Ruth Chena from the Renewable Thermal Collaborative. Thank you to Tim Sample for getting us connected with Steven Zaki at Olo. And last, certainly not least, our pal, Mr.

Aaron Eilers 42 L for getting us connected with Sam Brown from Server Farm. Wow. So there you go. Thank you. And by the way, listener out there, if you have people that you think would be a good fit for the show, send him our way. Cool. air.hot takes@train.com.

Dan Gentry: Takes a village.

Charles Jelen: Good one. You got a hot take today.

Well, I don't have a hot take. There was a listener hot take that was so good that I had, we got some

Dan Gentry: good listener Hot takes. I know they're

Charles Jelen: good. I'm liking it. So this is from Eric Wilson in in Louisville. You gotta say that right? Little Louisville. There you go. Yep. He sent in his hot take to the inbox.

Cool air.hot takes@train.com. And his was, I'm just gonna read it a little bit. He goes, I remember Beta max versus VHS and Blu-ray versus DVD. Mm-hmm. I experienced lawn talk versus Backnet and ZigBee v FY in the BAS industry. What I see coming a battle over data normalization. Oh. Yeah, it was good. All right, so here, here's what he wrote.

Everyone will have their BAS data in the cloud. It is going to be about the best way to organize that data so that it can be assembled by multiple systems for multiple purposes. Owners will wanna be able to use any analytics, ai, digital twin types, smart services from multiple companies. And to be able to switch between those providers.

Essentially he's saying that whoever can take all of the data that's in any one of our systems and get it into a usable packet for other third party companies to be able to use that is going to be like this transition or translation layer that is gonna be very valuable. That what

Dan Gentry: like Johnson Mo was talking about.

Charles Jelen: Kind of, yeah, like how do you get your data ready to be processed into ai? You can't just send AI loose on like disparate data sets. Yeah. It needs a little bit more than that. Needs to be trained. It needs a little bit. Yeah. So that is a great hot take. So thank you Eric Wilson for sending that in.

Appreciate it. That is

Dan Gentry: a good one. What's your hot take today? I couldn't help myself for this. And I have to say, on my way out to the studio this morning, I, I saw one so it just reinvigorated me. I am really hot on mini excavators right now. Mini

Charles Jelen: excavators? Yes. Whatcha you doing with the mini

Dan Gentry: excavator?

Well, so we got some, uh, we got a farm up, 40 minutes out town and we need to.

Charles Jelen: Mano area. Yeah.

Dan Gentry: Mano area. It's a beautiful area and we need some more trails. And my son is getting into dirt bikes and he needs a, he needs not want, he needs a Supercross track. So like a Supercross track. How do you go about building a Supercross track?

And then Trails and I, I was on Facebook and I stumbled upon these straight from the Chinese factory excavators for like three to 5,000 bucks. Nice. And they look pretty awesome. I've been watching some YouTube videos. I'm like jacked up about it. I'm really thinking like next spring I might become an excavator guy.

Charles Jelen: Okay.

Dan Gentry: I like it. And who doesn't need an excavator guy? I've, we'll have to do

Charles Jelen: like a remote show from the

Dan Gentry: land. Like a demo. Yeah. Yeah.

Charles Jelen: Alright. Remember listener, we want your hot takes, we want your questions as well. Let us know what you got. You can send us an email, cool air.hot takes@train.com. Leave us a review on Apple, or leave us a comment on YouTube or Spotify.

And as always, you can find all this information in the show notes for every episode.

Dan Gentry: Next, let's get to your HVAC headlines,

VO: HVAC. Headlines your news today.

Charles Jelen: It's 7 42 in Cairo. Here's your headlines. Hey. I got a headline for you.

Dan Gentry: Whoa.

Charles Jelen: Jumping

Dan Gentry: in on that. I headline. I gotta get in there. I gotta get my spot. I got a big headline. It is my birthday today. Hey, happy birthday. I'm 41 years old, so working my way into my forties. Feeling pretty good.

Charles Jelen: Well, very good. Headline number one. I can steal that. Let's go Dane birthday. I love it. Alright, headline number two for today, the Future of Cold Storage, innovation and Energy Efficiency. So this is from HVAC and Refrigeration Insider. Yeah, we talk a lot about. Comfort Cooling. We talk a lot about process cooling, data centers, industrial stuff.

We do not talk a lot about the cold chain. So the cold chain is, is all sorts of different areas of cold storage as well as transportation. So Trane has an entire business unit for refrigerated transportation. That's our Thermo King business. The major points of, of the article here is why does energy efficiency matter now more than ever, they cite rising costs, shifting regulation and growing demand for sustainable business practices.

The key areas that they came up with that the article cited is like, these are the growing areas of either energy efficiency or sustainability inside. Cold storage number one, which I am a big fan of, really good insulation for any application, but that's what they cited, is we need to move away from current technologies for insulation, move into extruded polystyrene or vacuum insulated panels.

Vacuum insulated panels, I think is. You think of Yeti, basically Yeti anything? Oh yeah. That's all vacuum inated. There's gotta be a

Dan Gentry: ton of opportunity in improving the performance of these buildings.

Charles Jelen: Alright, the second thing that they looked at here was smart controls. So just changing the way that you control primarily the, the compression system.

So today it's just, you run it for six hours. Off for a half hour. It's like base level controls on a lot of these. So how do you start to incorporate feedback controls, using thermostat, using sensors, whatever. Mm-hmm. Um, the third one, PCMs face change material. So this is being able to run your compression circuits longer so you don't have to cycle 'em on and off as much.

These PCMs, they essentially act as little storage devices inside the room itself. So you can put 'em on the walls, you can put 'em on the ceiling. If it's a really big warehouse, you can put 'em on top of the racks where they store material. But essentially what it does is you, you charge these materials up with just the air conditioning that's going on in the space.

They hold that energy and then when you turn off your equipment instead of the room, like instantly. Coming down to a set point, a little drift, and then firing back up. There's a drift period in there where you don't have to run anything.

Dan Gentry: Makes sense.

Charles Jelen: Um, so it just helps with, with reliability of the equipment.

And it can also help you in the middle of the day when it's the hottest outside and your equipment is the least efficient,

Dan Gentry: more capacity.

Charles Jelen: And then the last one was just pure mechanical efficiency stuff's getting more efficient, better compressors, better heat exchangers, better thermodynamics. Cool. So I thought it was a good headline.

Alright, headline number three, how we're making data center more flexible to benefit power grids. So this article came straight from Google in season one. We talked with Adam Scarsella from Volti about demand response, and that's what a lot of this article hits on. And one of the topics was how important it is for new, large loads coming onto the grid to be flexible.

Dan Gentry: Very important.

Charles Jelen: Very important. The reason it's important is because generally speaking, we don't have enough electrical power. To power all of the data centers or all the large loads that are coming online. And that's because a lot of times if the load is not flexible, you have to be able to send the peak at any given point in time.

Yep. And so you end up, not oversizing, but there's a safety factory where

Dan Gentry: Got a lot of generation

Charles Jelen: Yeah. A lot of generation for potentially a couple hours of the entire year where you're actually peaking. Yep. So what this article is getting at is if your data center can be flexible, which a lot of. Data centers actually can't be that flexible.

It depends on the workload going on in the data center. I was gonna ask about that.

Dan Gentry: Like some can, some can't,

Charles Jelen: correct. Yeah. And so if the data center, if the workload of the servers is for search based, if it's map based or cloud-based, a lot of those are just on all the time. 24 7 have to be available. But newer workloads, especially machine learning, they can be more flexible.

Mm-hmm. And so that's what this Google plant is doing. They piloted this in a facility in Omaha, proved it out, and now they're designing it into another facility in Fort Wayne. But essentially what it allows you to do is it gets you connected, interconnected, faster, because you don't need as much power.

You do not have to replace as much new transmission and new power plants. So if you think about it, like if, if the data center peaks at a hundred megawatts, they have to give them a hundred megawatts. At the worst case condition.

Dan Gentry: Yep.

Charles Jelen: But if Google says, Hey, I can turn everything off during those worst cases, there's extra capacity that's out there available.

Dan Gentry: Which in that case, that could be a lot of energy you're talking about too,

Charles Jelen: right? Yeah, absolutely. And so it, it allows, call it stranded capacity that if you're able to be flexible with your loads, you can grab that stranded capacity and use it throughout the year.

Dan Gentry: Interesting. Good stuff.

Charles Jelen: Alright, up next we've got Zach Sense.

He's the technician, productivity manager at Trane. Don't go anywhere.

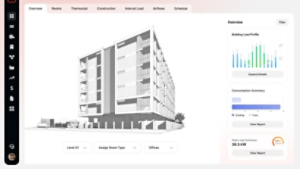

Dan Gentry: Are you ready to elevate your building design and analysis process? Introducing Trace 3D Plus from Trane.

Charles Jelen: Well, listener Trace 3D plus delivers faster, more accurate results through an intuitive workflow that aligns perfectly with today's building processes.

Dan Gentry: With

Charles Jelen: Trace

Dan Gentry: 3D plus version seven, you'll find improved functionality, more system configurations and outputs designed to support your business efforts.

Charles Jelen: Version seven also includes enhanced data visualizer upgrades, making it easier than ever to analyze and compare your designs.

Dan Gentry: Trace 3D plus making your job easier, your design smarter, and your buildings more sustainable. Visit trane.com to get started today.

Charles Jelen: All right, listener, we've got with us today a blue blood baltimorean. I think that's how you say it. We'll find out shortly. But this guy loves all Baltimore sports teams. He's a skilled bartender. He's a dad to two boys. His dad is a technician. His uncle is a technician. He is was, we'll find out a technician.

Needless to say, a white windowless van in this guy's driveway is not a site he's unused to. Welcome to Cool Air, hot Take accents. No problem. Thank you guys for having me. I appreciate it. All right. So give us the, your dad's a technician, uncle's a technician. I'm assuming that's how you got into this.

Zach Zentz: Yeah, so my father started years ago. He is been with train around 35 years at this point. Oh, awesome. And then my uncle, my dad's brother was also a trained technician in the same office. My father's still a technician with the Baltimore train office. Nearing the end of his career, but not quite there yet.

Dan Gentry: Alright. And your boys are trying to be technicians too, I assume.

Zach Zentz: Yeah. My son has said he wants to work for Trane, but I said that a lot too when I was younger and my father tried to push me other directions. I, I tried many for a while and then ultimately found, you know, it was a good living, so decided to take it up

Charles Jelen: Nice.

Alright, well the name of the show is Cool Air Hot Takes. We ask all of our guests to come on with a hot take, whether it's personal, professional, anything in between. What's the hot take for today's episode?

Zach Zentz: Uh, can I give you two? One personal, one professional. Oh, absolutely. Yeah.

Charles Jelen: Love it. Yeah.

Zach Zentz: All right.

We'll start with the personal one. Personal is back in 1996, Jeffrey Mayer was a 13-year-old kid who robbed a catch from Tony Toco in game one of the 1996 American League Championship series with the A Yankees and Orioles, and that sent the Orioles on a downward spiral. And it was the incorrect call. It was not a home run.

Should have been an out, uh, it's like it was like Bartman before Bartman kind of thing. Yes. Yeah. Okay. Exactly. Exactly. As OS fans, were still suffering the fate of a 13-year-old back in 1996.

Dan Gentry: Oh, wow. What a tragic story. Yeah.

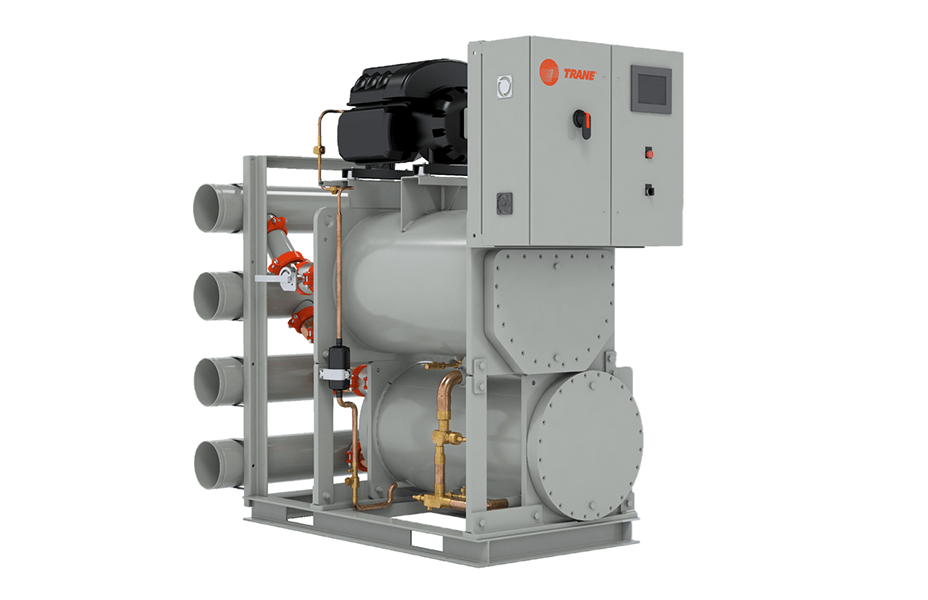

Zach Zentz: Professional is one. A discussion I had with a manager. Years ago when I first got into the trade where I was told that get away from water, cool chillers, they're a thing of the past.

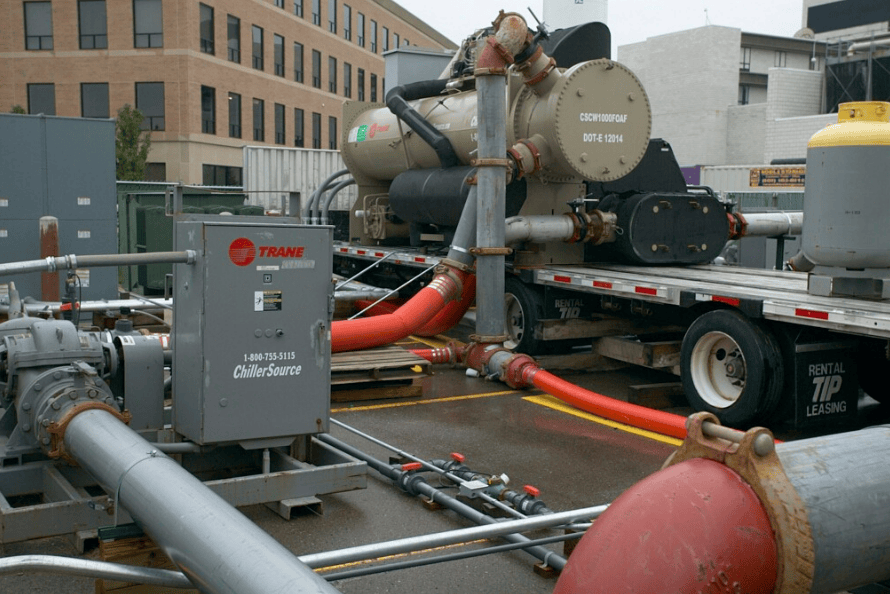

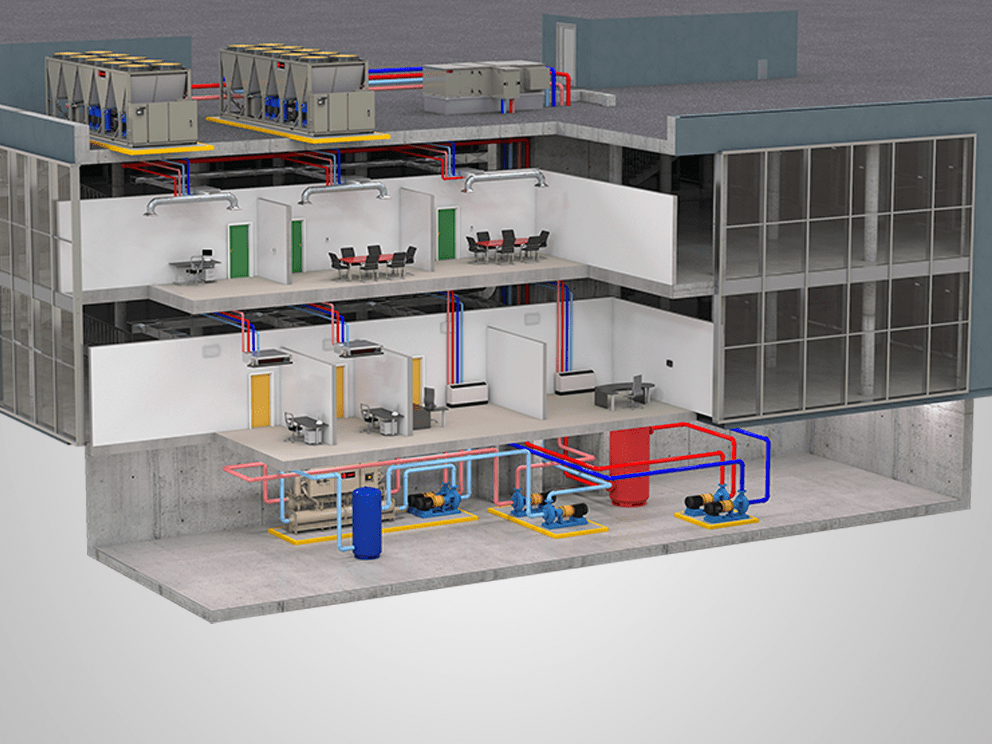

It's not the way the future will be. Granted, this was 14 years ago and I think that recently things have turned, uh, water cool. Chillers will be around for quite a while.

Charles Jelen: Alright. Yeah. Wow. I hadn't heard that. That's interesting. Product managers on the water cold side everywhere are, are applauding. You Alright, z You're a technician.

Productivity project manager. What does that mean? What do you do for tra

Zach Zentz: Uh, man, anything and everything related to technicians I'm involved in. The new product development teams, I sit on a lot of the meetings, um, from a serviceability and service tools aspect. Do you know what is the best way that we should design some of our pieces of equipment so that techs are, have an easier job of working on 'em, or they're able to accurately do the tasks that they need to do to maintain and repair the equipment?

And then also, do we have the tools in the field that we need to be able to do that work? Or do we need to prepare the field with new tools, new equipment to make sure that our service techs are able to service the equipment? In addition to that, we are running a new hire technician onboarding program where we're centralizing some of the tasks that our managers need to do to bring a new technician on at train to try and support the regions with some of the massive growth that the train service has seen in the past number of years.

And we're also running a pilot around parts delivery. Making some of these things available to our technicians on demand and just keeping in touch with various parts of the business and making sure that a technician's opinion a technician's needs are part of the conversation and they're considered when some of the decisions are made.

Charles Jelen: There are lots to jump into there, but I think one of the common themes that you hear, no matter who you talk to in, in terms of an OEM or any contracting business, is the lack of technicians available today. So let's start there. What, what are some of the biggest challenges that our industry is facing On the technician front,

Zach Zentz: the number one thing is just availability and the numbers.

I think trade schools at the high school level are, are much fewer and farther between than they used to be in years past. There was a big drive for a number of years around. You have to go to college, and I was coming through high school at that time as well. You know, I went to a school that prepared me to go to college and I did go to college and ended up finishing my degree.

But I got about halfway through college by the time I decided, hey, I, I think I wanna pivot to something else. And then, you know, I enjoyed doing something different every day, working with my hands, working on the type of equipment that we work on. So I think the number one challenge really is just.

Finding the talent available. Uh, luckily within Trane, we have a number of resources for that, but there's a bigger industry issue that probably needs to be looked at from making sure that we're preparing individuals that want to pursue work in the trades. Mm-hmm. To make sure that they have the tools and they have that step when they eventually get into the workforce.

Dan Gentry: So from your perspective, do you think that's changing at all? We're getting more kids interested in the trades. 'cause I have to say I did the same thing that, that you did. I went to college after high school and I don't think I should have right away. I should have gone to the technical college or something.

Would've been what?

Charles Jelen: Pharmacy wasn't right for you? What are you trying to say?

Dan Gentry: Does it? There you go. I, I blame the high school. I blame my guidance counselor. But no. Do you think that's changing?

Zach Zentz: It seems like the conversation is taking place more often now that, you know, the trades are an acceptable way to go, an acceptable career, and seeing that there is a need for individuals in the trade.

So I think the conversation shifting, the second step would be getting the infrastructure in place to support the individuals who do want to do that or choose that route. Like, you know, shop class seems to be a thing of the past in most high schools. And thinking about the days when my father went through, you know, he split his time between traditional high school and a vocational high school.

There's not the diversity of different trade classes offered to some of the kids coming through high school these days. So even in my time I had to finish high school, then go do trade school after that. I think starting to get some of those kids into the trades during high school and maybe coming out a first year apprentice, second year apprentice, third year apprentice, it is.

On its way. We just really have to start making the investments and I think companies driving it is a big help. I think we're starting to, we're just not quite there yet.

Charles Jelen: Got it. Yeah. What's the minimum requirement for a technician to come in and and be a trained technician? Do you have to have some accreditation or can you come on with trained right outta high school and then work that way?

Zach Zentz: So Train does have its own internal tap program where we will take individuals potentially straight out of high school. The local office will send them to the TAP program where they will spend time in the field learning with our technicians as well as in the classroom. Cool. Basically going through a, a train internal apprenticeship.

Mm-hmm. And then depending on the areas, they have different routes. There are things like, we have sort of high school internships where we. Do potentially have high schools that do have some kids with interest in the trades and we can partner 'em with a trained technician a couple days a week during the summer to see if that is a path they wanna pursue down the road.

And then, you know, the good thing is we get to test them out, see their interest level, and if they work out, we're feeding our own technician force.

Charles Jelen: Love it. Nice. What's, uh, okay, so other than just the raw availability, the number of technicians out there, talk to our listener a little bit about what, what a technician does on a day-to-day basis.

For those that don't know what a technician does, give us an idea. Day in the life. Basic just intro to what a technician is and what they do.

Zach Zentz: We have, I'll say three main types of work here, which is number one, maintaining equipment that's operating, doing your inspections, doing your preventative maintenance to make sure that that equipment continues to run.

We also then have startups where a new piece of equipment's come into the field and you're gonna start it over for the first time, log it, make sure that it's ready to go, and it's operating the way that it should be, as of it leaving the factory. Mm-hmm. And then we also have just standard service call work.

Somebody calls and says, Hey, I'm too hot. Hey, I'm too cold. We need somebody to come out and look at the equipment. One of the things I loved about being a technician was every day I was driving to a different building. Every day I was driving to a different area of town, seeing different things. It was a new challenge.

Interacting with different people was something that I always enjoyed. You know, you get in your truck in the morning, you look into your cell phone, see what your call is for that day, and then you prepare for the day, drive to the job. You start the job. You may be ordering parts, you may be. Looking up parts, you may be using a laptop quite a bit, maybe using your tools the entire time.

Mm-hmm. I think the biggest challenge these days seems to be that we're using our laptops as often as we're using our toolbag anymore, which is a change in the field. But I will also say that the younger techs coming in, they have an aptitude for that already, which is great. Mm-hmm. And honestly, you'll be surprised how often the older techs are teaching the younger techs mechanical skills and the younger techs are teaching those older.

Text, the computer skills and the troubleshooting involved in that way.

Dan Gentry: I like it. Yeah. Trane has a ton of different kind of products from, you know, residential all the way up to Cent Vac that we are here in lacrosse. I assume a technician doesn't just start like, Hey, go start the Centra vac up. How do you get, uh, is it training or how do they get from different, maybe like one level to another or like a type of product or what does that look like?

Zach Zentz: So number one in the field, training with another technician is the most valuable at all times that hands-on knowledge, learning, learning on your own with another individual who's experienced in that type of equipment day to day. That's, that's the number one transfer of knowledge that's happening with any technician.

And in addition to that, there's just a bunch of resources available to us that we have. The greatest thing now is, you know, in years past, it used to be an actual hardcover books or hard copy books, and every tech had a shelf on their truck full of. Individual books, all of those things are available online now through PDFs, so I can carry any number of manuals in my laptop and be able to access, you know, just a plethora of information that I need.

The new equipment is probably the hardest to keep up on just because newer styles of equipment are coming out faster than they ever have before. So technicians are typically. Very familiar with the traditional Trane brands that have been around for years. And you know, they've built their legacy, the rts, our Cent vx, all of those.

But the newer stuff, there's just tweaks to it to make it operate a little differently. Those are the things you wanna research and learn, and honestly, as a technician, there's a lot of research on your own time.

Charles Jelen: Huh? Yeah, I bet. And, and especially in the, in the space that we're in now, the amount of new product coming at you guys is probably double now.

Oh yeah. Than it, than it was 10 years ago. With everything from the expansion of the products and data centers, and then the products on the heating side of the business for heat pumps.

Dan Gentry: Yes. I mean that's crazy 'cause like we can't even keep all this stuff straight, but you guys have to keep 'em operational and maintained.

Zach Zentz: Yeah.

Dan Gentry: That's gotta be a task.

Zach Zentz: It's a challenge. Especially now, you know, things are operating differently than they ever have before. It wasn't happening very often in the past that things were heating and cooling at the same time. Mm-hmm. Now you have that. That's a common. Thing that that's occurring in, in a lot of buildings.

So yeah, it is. As a tech, it's difficult to stay on top of. But it, you know, the biggest thing for any technician is if you, if you're facing a challenge for the first time, you haven't seen it, just kind of step back to the basics. Everything operates under the same principle. Start from there. We always say like, Hey, cut the problem in half, eliminate one side.

Now you're focused on the other side. And honestly, being part of a good team is a big part of that. Having those resources available internal that you know, you can call at any time and they'll pick up the phone, it points you in the right direction, even though they'll. They'll rarely solve the problem for you, but just getting you pointed in the right direction.

Sometimes staring at something for too long, you need to take a step back and listen to another voice.

Charles Jelen: Yeah. So you talked about new product development and that's part of your new role. What are some of the things or the thing that you're most excited about for technicians that's on the horizon?

Zach Zentz: Oh, man.

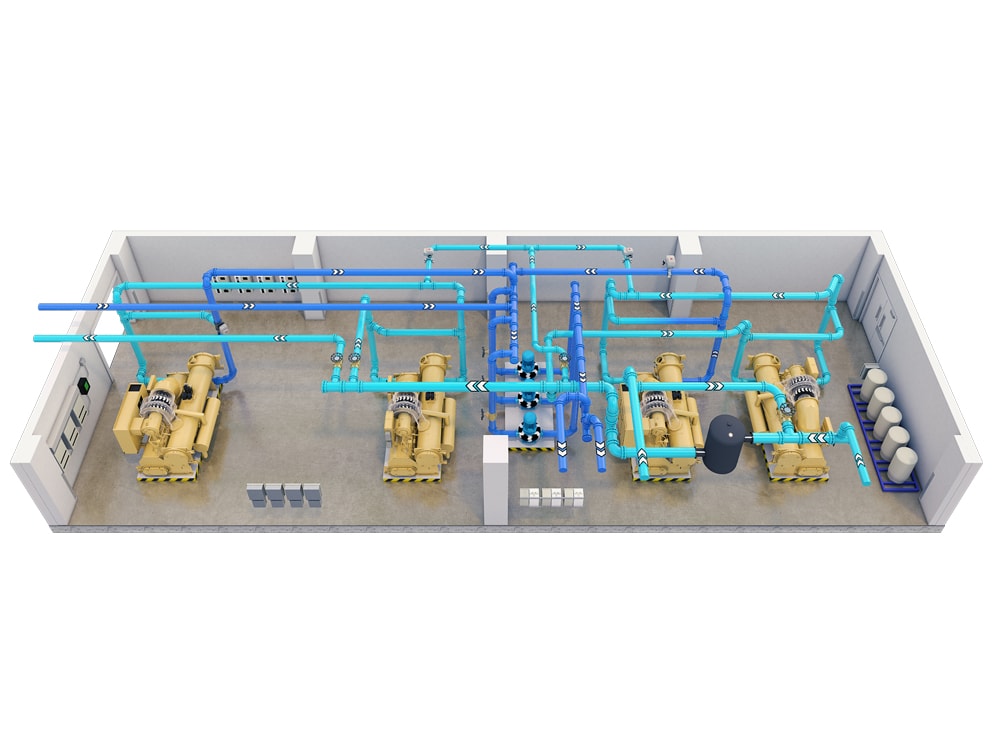

Um. Everything in the data center world is just amazing. It's a new window of opportunity for us, to be honest, I I, I did not work in data centers when I was in the field. However, hearing the stories and, and being able to envision, oh, you walk into a building and it's, it's just a row of chillers. I mean, that's my dream.

That's, you know, never having to pick up and move each day is huge. And being able to see the massive amounts of energy and cooling being produced by these pieces of equipment and knowing that, you know. You have a big part in keeping that stuff up and running that entire world. The mission critical spaces.

Sometimes you think it can be more stressful and it is, but also when you solve that problem, you feel like a bit of a hero too.

Charles Jelen: Yeah, we hear a lot about productivity with new tools, especially AI or using data. Are you getting in any of that or anything that you can share with the audience here?

Zach Zentz: Yeah, you know, we are constantly looking for ways to integrate anything that is gonna make our technicians more productive, more efficient, and make their jobs a little easier.

So there have been some beginning stages around things like ai. We do provide them different tools where they may send a snapshot of a serial number and it kicks back some information for them automatically, whether or not they need to utilize it. The key is just that it's there for them at their fingertips if they need it.

And that's just sort of the tip of the spear where it comes to that we're, you know, constantly looking for, for other ways to make our techs jobs easier in the field. They get hit from a lot of different directions. So, you know, one of the things I always sort of say is that, you know, the techs job is to turn wrenches for eight hours.

That's what we bill for. That's what we charge for. That's, that's the technician's job. But they do a lot of other things in that eight hours. So you're still expected to be able to accomplish all of that. And do your eight hours worth of wrench turning. So any way we can shorten the time that they're looking for other things, IDing parts, ordering parts, going to get parts, all of those different items, it just makes everybody's job easier and keeps us moving.

How does Connected Mechanical fit into all this? Connected mechanical is huge. Being able to, number one, trend a piece of equipment, that's a huge benefit. As a technician, you would run a lot of service calls where you show up and the equipment's running and they say, well, yesterday it did this, and your answer sort of.

Well, it's working now. I can only tell so much from what it did and you can look into things and Id some things, but being able to run a call the next day and see that, hey, at 2:00 AM all of your valves slam shut. We lost flow. That's why you're chiller tripped. That's an added service to the customer.

They feel as though you've given them an appropriate resolution to the issue they're bringing to you. Being able to roll less trucks and being able to log in remotely and see a site maybe before I even go to the site potentially I is huge. It also builds a little more trust with the customers. It provides them a greater service, and as a technician, any additional tools I can get are tools that I want to have.

Charles Jelen: Love it. Alright, let's, let's close this out. Yeah. You've, you've been a technician a long time. You've been in and around the technician space. What is the craziest, weirdest story from a job that, that you've heard? Oh man,

Zach Zentz: there's so many, but, uh, the, the one that I. Took part in myself was, we had a, a job site in Baltimore, a big casino that was going up and a lot of crazy things went on every day that we showed up.

'cause the casino was open overnight. We'd show up at 6:00 AM and each day there was, we would walk in, check in at the security office. There was a big wall of individuals who had been permanently banned and all the crimes they'd committed. Against the casino the night before. So we enjoyed showing up, handing our IDs over each day and reviewing the board to see who had been out.

Um, I was part of a conversation where one individual had apparently been permanently banned from the casino three and four times, and one of the notes under his name said, how does he keep getting in here? Um, and Harry Houdini. Yeah, that same casino. We worked what was supposed to be overnight. Um, but turned into essentially 20 hour shifts for three weeks straight, trying to take a piece of equipment down, make the repair, get it back online all within the same day.

And that was in single digit temperatures outside. But then when we stepped into the equipment, they were big custom air handlers. The, the inside the air handlers was around a hundred degrees, so we were fully suited to go on the roof and as soon as we stepped in, had to take everything off. And the site developed a nickname for sometimes the lack of maintenance or some of the items they would choose to do, but it was a constant thorn in our side as technicians.

We knew when we got called there, it wasn't gonna be a fun trip.

Charles Jelen: You know that sauna cold bath, that's like a thing today. Now, like all the kids are doing it.

Zach Zentz: If somebody had walked on the roof not knowing we were in that unit working, it would've looked like three guys just evaporated on the rooftop.

Charles Jelen: Alright, Zach, well great. Thank you for giving us a little peek inside the life of the, the technician world. Really appreciate the conversation today.

Dan Gentry: Yeah, thank you.

Charles Jelen: Sure, no problem. Thank you guys.

Dan Gentry: Ready to electrify your next HVAC project. Trane leads the way with heat pumps and heat recovery solutions designed to meet demanding market needs and evolving regulations. From project design to installation, Trane is your partner in smarter greener electrification of heat. Wanna stay ahead of the future of HVAC products?

Don't miss out. Visit trane.com today.

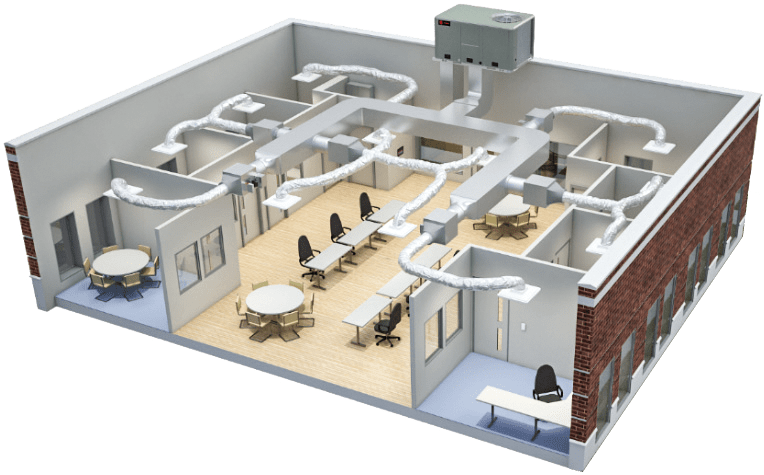

Charles Jelen: All right, listener, we got a fun one here in honor of everybody completing their fantasy football drafts. We wanted to do one as well, but instead of, you know, your traditional NFL football, we are going to do application engineering fantasy draft. Yes. For those who don't know, application engineering is kind of a, a, a famous group inside of Trane.

These are some of the best in the brightest that have come up. They do a lot of work on system level engineering, so how do you take products and pieces, put 'em together with controls over the top to optimize the system for whatever you're trying to optimize for. All right, so Dan and I are gonna play rock, paper, scissors to see who goes first.

We're gonna draft a quarterback, a running back, a wide receiver, a defense, and a kicker ready?

Dan Gentry: Okay.

Charles Jelen: Rock, paper, scissors, shoot. Oh, scissors, tide. Rock, paper, scissors, shoot. Yes. One with a rock.

Dan Gentry: First pick. Alright. Well I think we both know who's gonna probably go early in the first round and I. Luckily, take Mick Schwer as my quarterback.

It's a no-brainer choice. He knows the game, he knows everything in the industry. He's a leader in what he's good at. He's very smart. And he's gonna bring my team yeah, to the championship.

Charles Jelen: Recently retired Mick Schwer, applications engineering for a long time. Uh, 42 years. National ASHRAE president. Kind of an easy number one pick.

Yeah,

Dan Gentry: I mean, it's like, Hey, I'll take to,

Charles Jelen: I get it. I get it. Alright. My number one pick. I'm also gonna go quarterback John Murphy.

Dan Gentry: Okay.

Charles Jelen: One of the best in the industry. If you've ever met him, one of the most helpful people, he sat right behind me. He was probably very annoyed with me because I had to ask him every question that came in.

Number one, pick for me. Number two, overall solid.

Dan Gentry: Pick my quarterback, solid pick. I'm gonna pick a running back. Mm-hmm. I'm picking Ben Kora for my running back. Oh, you know why? You gotta think about this position and you can just. Give him the pig skin. He cuts through the line and makes progress. Like he's so consistent.

He's my pick. I feel good about it.

Charles Jelen: I like it. That's a good one. Alright, with my second pick, I'm gonna go defense. I'm gonna draft Lee Klein as my defense. Okay. One of the best in terms of hydronic design. He knew how to get water where it needed to go. Yep.

Dan Gentry: You know, I mean, he's obviously gonna go high in this draft, so no surprises there.

There you go. I'm gonna pick a wide receiver next. Okay. And I'm picking somebody who was on the team. I'm picking you for my wide receiver. I need somebody that can be very reliable. You're gonna throw the ball down the field. You need them to catch it. Got some feet. Turn that defense into burnt toast. I'm flattered.

I'm flattered

Charles Jelen: you're next. I like it. All right, my running back. Dave Guck Berger. Okay. I never worked, worked with Dave, but I know the name. Yes. Not only does he have a fantastic last name. Yes. Guck Berger, but another great guy, one of the best application engineers out there. He's my running back.

Dan Gentry: Okay. I'm picking a defense as well.

Okay. I'm picking Justin Ween for my defense. Okay. You want somebody to put up a wall? You want this guy to stop the offense? That is it. I don't even have to say much more. I think that's a solid

Charles Jelen: DI like it. All right. My wide receiver is Paul Solberg, the soul man.

Dan Gentry: Okay.

Charles Jelen: If you needed a split system, he was the guy.

Probably still is. I think a lot of people miss him out in the field.

Dan Gentry: Yeah,

Charles Jelen: a lot of people do. We get asked for,

Dan Gentry: Hey, who took over? Who's the new Paul? Uh, good question. No, that's a good one. Uh, rounding it off with a kicker. Mm-hmm. You know, you need somebody to change the position on the field, right? Oh, yeah.

I'm going with Ryan Geister for the kicker. You can really change the position.

Charles Jelen: There is a little caveat there. He never actually was an application engineer. He managed.

Dan Gentry: I know. I figure like, eh, that's okay. That's all.

Charles Jelen: We'll let it slide. Thank you. Alright, my kickers. What's one thing that a lot of kickers have in common?

A little quirky, a little, little different, you know? Yeah. Yeah. Yep. That's fair. All right. My

Dan Gentry: kicker, Dennis Stankey. Okay. I actually met Dennis Danky at a retirement party not too long ago.

Charles Jelen: Well, it must have been a good party because talking to Dennis is, is great. If you have a chance to talk to Dennis, he's, he's an awesome guy.

Uh, he's always got something fun, always got something interesting to say. He's my kicker. So I'll, I'll run down my quarterback. John Murphy running back. Dave Guck Berg. Wide receiver. Paul Solberg defense Lee Klein kicker. Dennis Stanky.

Dan Gentry: Nice. I got quarterback Mick Schwer running back. Ben Kora wide receiver.

You defense Justin Weiman and kicker Ryan Geister?

Charles Jelen: Yeah, my team's kicking your butt. It's not even close, eh?

Dan Gentry: I feel pretty good about it.

Charles Jelen: All right, up next we got Stat of the day. Stat of the day. Here comes Joe Day. All right. Listen to your stat of the day is highest paid athlete by sport. Daniel, you wanna take a a shot at what sports are in the top 10?

Dan Gentry: I mean, I would guess football, baseball, NBA Formula One.

Charles Jelen: You are one of the top four. Okay, let me start on number 10. We'll go 10 to one. Number 10 is Fabio Cortaro Row. Moto GP makes $14 million a year. That's Moto. Is that, is that uh, like crotch rackets? I it must be, yeah. Moto gp, Moto Grand Prix. Uh, number nine WE Pro Wrestling.

Oh yeah. Makes it. Roman reins is making 15 mil a year. Oh yeah. NASCAR, Kyle Busch. 17 million a year. Dak Prescott, NFL 60 million. That was a big jump from NASCAR at 17 to NFL at 60. Uh, Dak Prescott's number one. Number one in baseball is Shhe. A 70 million. N-B-A-S-G-A from the OKC Thunder 71 million max for Stepin Formula one 72 million.

Canelo Alvarez boxing 73 mil. This is a year, by the way. Uh, golf number two. Bumping up a bit. Yeah, with all that live money out there, John Rah makes the list number two, a hundred million a year. Number one with a bullet, not even close. Christiano Ronaldo is making $234 million a year.

Dan Gentry: 234, 3 0 4. He's got a couple hundred extra grand.

A lot. That is, wow. That's insane. That is a lot. 200 million to play soccer. It's

Charles Jelen: a good gig if you can get it. Yeah. Might as well. Well listen, that's your stat of the day. Uh, unfortunately, Dan, you didn't make the list this year. Maybe next year.

Dan Gentry: Yeah, next year.

All right. Thanks for listening to this episode of Cool Air Hot Takes. Thanks so much to Zach Zenz for joining us today. It was a great interview. Thanks to the cool Air Hot Takes production team, Elena Ye Bailey, Ainsley, Katie

Charles Jelen: and Kristy. Thank you guys. All right. Send us your questions and hot takes by leaving us a comment on Spotify or YouTube.

Leave us a review on Apple. Drop us a message@coolair.hot takes@train.com. Don't forget, you can also rate us wherever you listen. Five stars will be great.

Dan Gentry: Until next time, stay cool and keep those takes hot.