Charles Jelen: You are listening to Cool Air Hot Takes.

Dan Gentry: Welcome everyone to Cool Air Hot Takes. You're listening to one of the top podcasts in the world that features two HVAC professionals that met in middle school. Now, you may not know that category exists, but it is a pretty huge one and people are

Charles Jelen: talking about it. I'm Dan, and this is Charlie. Thanks so much for being here.

Every couple of weeks we get together and bring you the latest in HVAC news, a couple of hot takes and expert interviews with industry leaders this week. That interview is with Sam Brown, he's the Chief Development Officer for Server Farm, one of the world's leading data center providers, and we're gonna talk about.

You guessed it just like it sounds. We're gonna talk about data centers specifically. We're gonna get into site acquisition, the challenges that they face into some of the next generation technology that's headed our way. We're also gonna bring you HVAC headlines, another episode of Dan Inside the Factory.

If you've got names for that title, please send 'em our way. Cool layer.hot takes@train.com and then we'll finish up with stat of the day. Ooh, gonna be a hot episode. I like it. Alright, Danny, boy, I had. A epic week of pop in culture. Buckle up. If you're not familiar with pop in culture, go back to, I think it was season one, episode two.

Give it a listen. But Tucker had a baseball game. Millie had a baseball game. There were an hour in between 'em, and we had an hour to kill. So what do you do when you've got an hour to kill? Popin. That's right. Yep. Stopped over to, uh, uncle Jimmy's, aunt Kayla's, hell a cocktail hung out, you know, fixed their internet.

Helped him out a little bit the next day, driving by my parents' house and I see my Uncle Kyle's truck in the driveway. Alright. And that is an absolute homing beacon. Like if, if you're into pop culture and you see a car that you know isn't normally there and you have that opportunity. To bring an extra popin to a pop-in that's already happening.

Is that a pop-in party? It's incredible and I hate this term, but I'm gonna use it. It's the only time where it's applicable is where one plus one might equal three. That is awesome. Double pop-in back to back days. It was great. I love that. Alright, what do you got for a hot take this week? Actually? I think I want you to go first.

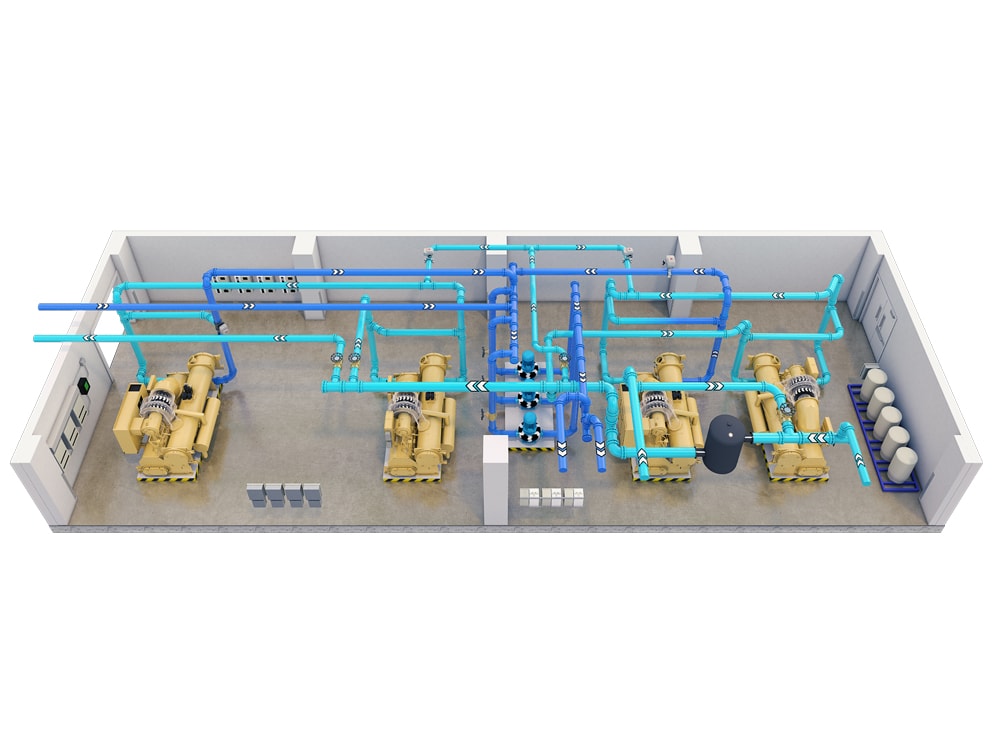

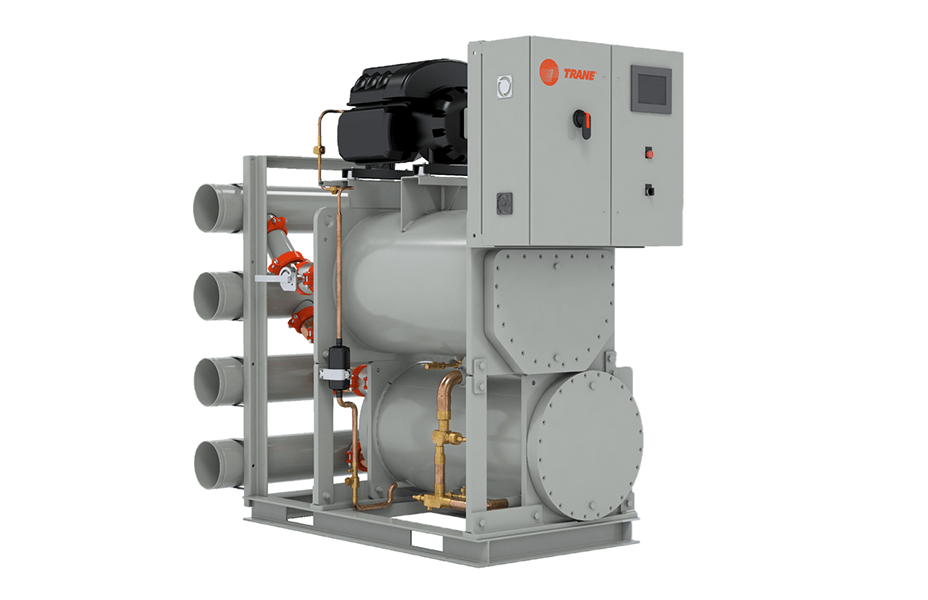

I'm gonna go first. All right. I'll go first. Yeah. I wanna hear yours. Okay. Mine's plant sizing. Mm. I'm a big fan. I don't know where to draw the line here. So let's go. Chilled water plant sizing. It's a topic we, we talk about often. You far more than I do, but for maybe, I don't know. Let's draw the line at a thousand tons.

We'll call it a thousand tons. If you're designing a plant less than a thousand tons. My hot take is that you should. Not be designing them with all the same size chiller.

Dan Gentry: Yeah. You know, you need some, uh, some low end, turn down. Maybe like a pony chiller.

Charles Jelen: Yeah. Pony chiller, heat recovery chiller, something to maximize the efficiency of the units that you put in there.

Totally understand that that is a more complicated system, but with the controls that we have these today with chiller plant control, it is not hard. To adequately stage and, and with sensors like, you know, the load that's in the building, or you should know the load that's in the building. Mm-hmm. It's a new plant, you know where the load is and you know the capability of the plant that you have there.

If you're looking to maximize efficiency, reliability. My hot take is we should stop designing plants with all equally sized chillers.

Dan Gentry: That's hot and I like it, and I agree. Alright. What do you got? Uh, why'd I have to go first

Charles Jelen: here? Well, because now I'm very curious.

Dan Gentry: You know, it was kind of a, like, it was a setup.

It was a, it was a setup. You're setting me up. What'd you read?

Charles Jelen: You, do you, do you read my notes?

Dan Gentry: Uh, you know, I sometimes I like to do a little dabbling just to, you know, make sure this all works. But, um. Because you brought it up, you brought up chiller plants. I'm gonna stay in, in chiller plants. And, uh, I'm also going to give a little shot to my buddy, uh, Mr.

Espresso out in, uh, Minneapolis, who was actually just full of hot takes, uh, the other day and was so full. I think he had to go cool down actually.

Charles Jelen: So it's more than just hot air. There's some, there's some takes in there too. Yep. Yep. There are some takes. Just kidding. Mr. Expresser.

Dan Gentry: It was a great one though and really aligns with yours.

But, uh, this take, whenever you're looking at replacing a pony chiller, which is gonna be a smaller chiller, maybe a swing chiller, some people call him in a plant, look at replacing that with a heat recovery chiller.

Charles Jelen: There you go.

Dan Gentry: A lot of times that's a smaller unit. It, rule of thumb, it kind of works out pretty well for capturing some heat.

Uh, you know, it's not gonna be every single time that works out, but definitely something you should look at and consider. When you're in that situation, so thank you espresso, and make chiller plants hot.

Charles Jelen: Make chiller plants hot again. Yes. All right. Remember listener, we want your hot takes as well. You can send us an email, cool air.hot takes@train.com.

You can leave us a review on Apple, or you can leave us a comment on YouTube or Spotify. You can also find all of this information in the show notes of. Every episode. Next up we've got your HVAC, headlines,

VO: HVAC. Headlines your news today.

Charles Jelen: Alright, listener, it's 7:00 PM in Madrid. Here's your headlines. Alright, this is less of a headline, more of an industry trend. There was a couple headlines that, that I've read over the past couple months, so just kind of conglomerated them into one. All right? But the general trend is private equity, buying up independent contractors.

Why? Great question. Alright. And now this goes out, uh, there's a couple people that have, uh, that I've worked with in the past that have gone into this space, uh, open invitation to, uh, send letters to the editor, you know, uh, to, to correct us or to provide their opinion on this one. But I'm just reporting some of the stuff that I've read, just the facts.

It's, well, I don't know. You know, it is hard to know what facts are, uh, when you're doing Google research books. Uh, all right. So according to PitchBook, over 800 MEP contractors have been acquired by private equity since 2022. Wow. A lot. Alright, so some of the major reasons why this is happening. One is private equity in these firms that are looking to, to invest their money, the MEP space.

So smaller mechanical contractors are looked at or are seen as fairly recession proof. They've been very resilient over the years because people need heating, they need cooling, and mm-hmm. Those are the people that are servicing that equipment and installing that equipment around the country. There's a perceived opportunity for operational improvement, so efficiency of scale.

If you can take a small mom and pop shop and you can combine 10 of them together and kind of combine that back office, create processes, you can potentially improve the efficiency of those businesses. There's a growing demand generally across the country for higher efficiency units. A lot of that is code driven, but then there's also parts of the country that are looking to.

Go with heat pump solutions, which are just generally more technical in nature and require a higher level of technician to install some of those pieces of equipment. Mm-hmm. And then the last bullet that I have here is fragmented across the country. So there's lots of small operations combining that into scale.

Consistency. Yeah, there's, there's opportunity for private equity. So here are the perceived positives of private equity coming into the space. The first one is it offers an opportunity for mom and pop shops to exit the business at, at probably an attractive price. You know, who knows what they would've been able to sell their business for locally.

And so having this bigger company come in and, and offer them what they perceive as the worth of their business, that gives 'em a potential out. So that's one, uh, potential to infuse capital into a business to make it grow faster.

Dan Gentry: Mm-hmm.

Charles Jelen: And so if you're, if you're a small company and you wanna retain the ownership, but you know you want to grow and there's this outside company that's willing to take a stake in the company and potentially fund some of that growth, it's potential upside there.

Yeah. Um, and then potentially you, you could have lower fixed costs and operating costs with, with larger scale. So if you combine a bunch of mechanical contractors together and you, you can buy at larger scale for components or service you, you potentially lower the cost of the business. Hmm.

Dan Gentry: Yeah,

Charles Jelen: that makes sense.

So those are the perceived positives, perceived negatives here. Right. And this is where I, I would love to, to get some feedback, is there is likely going to be a culture shift. From like a relational business to more of a metric driven business. More of a corporate environment?

Dan Gentry: Yeah, like kind of like, you know the guy who's preparing your thing because you have coffee with him on Sundays or whatever.

Yeah. Who,

Charles Jelen: who fixed your

Dan Gentry: water here? Mr. Uh, hay. That's right. Ralph Plumbing. He did a heck of a job. And he's a buddy. You know, and like it's Uhhuh.

Charles Jelen: I, I know him. Yeah. Well, we won't talk about why you needed to fix it. Uh, another one is potential rising costs to meet revenue targets. If you don't realize the efficiency that you think you're driving into the business and you've got these revenue targets or margin targets that you're looking to hit.

Yeah, could actually see the market go up. And then also if you combine a bunch of local, smaller competing contractors into one business, lower the competition in a given market, which potentially could drive the cost up as well.

Dan Gentry: Yeah, that's an interesting headline. I guess we'll see what happens moving forward.

Charles Jelen: Yeah, certainly a trend in the business. If people have information out there, I would like to share their opinion. Send it our way. Cool. air.hot takes@trane.com. Alright, up next we've got Sam Brown. He's the Chief Development Officer at Server Farm. Don't go anywhere.

Dan Gentry: Hey there, listener. Join 2020 five's top VRF, questions answered. Webinar on September 24th from three to 4:00 PM Eastern. Our ductless experts will answer your questions about best practices regarding VRF installations.

Charles Jelen: Doesn't matter if you install VRF systems daily or you're just getting started, we've got you covered.

Tune in. Grab the answers you need on everything from refrigerant, piping to control integration, and get back to the job with confidence

Dan Gentry: out in the field during the webinar. No worries. Watch it whenever you want. On demand.

Charles Jelen: Go to trane.com or click the link below to register.

All right, listener. Of all the intros I've put together for guests on the show, this one has to have the highest potential for getting cut by legal. Um, Sam, your, your friends, your quote unquote friends here, they did not hold back on stories. Uh, they, they spanned things from, uh, hikes gone sideways in Hawaii, groomsmen getting DUIs before the rehearsal dinner.

Uh, USA World Cup cheers during a wedding ceremony. They really covered some ground. We're not, we're not gonna go down that route. Where we will start is, uh, listener we have with us today, a, a real data center professional. He's been in it his whole career. Graduated from, uh, Mizzou and went right into the data center space.

And he'll tell you all about his professional career in a second. Uh, but when he's not at work, it sounds like you can find him in one of two places. First is on the soccer field. He has three boys, by the way. I, I think our kids are almost identical in age. Mm-hmm. Uh, and second is on the links because this man here has an index.

Under two is what I hear, which is incredibly low. Uh, so welcome to Cool Air Hot Takes Sam Brown. Thank

Sam Brown: you guys so much. Happy to be here.

Charles Jelen: Alright, so name of this show is Cool Air Hot Takes. We ask all our guests to come on, uh, bring us a hot take, whether it's personal, professional, anything in between. So did you, did you bring a hot take?

Sam Brown: Yeah. Uh, I don't think liquid cooling is gonna stay around. How about that one?

Charles Jelen: Whoa. Oh, okay. Okay. So give us, give the listener a little background on the difference and and why that is such a hot take.

Sam Brown: Everything within our customer delivery pipeline right now is based on liquid cooling. They're trying to get higher density cabinets and just fit more compute into a smaller space.

Liquid cooling is a much. More effective means of cooling these servers and facilitating a lot of the AI growth that our customers are chasing right now. But I just see there being this challenge with, uh. Something's gonna go wrong and someone's gonna fry like a billion dollars worth of GPUs or something.

Charles Jelen: Right. So like the typical technology that's at use today is either air cooled or liquid cooled, and there's this growing sentiment that everything is gonna shift to liquid Cool. In the not too distant future. And you are saying. Pump the brakes on that. What do you think? You think we're gonna stick with air cooled, or do you think there's gonna be another technology?

Sam Brown: Honestly, I think that rear door heat exchangers, like close coupled air cooling, gives you an appropriate sort of safety factor in terms of the system being able to withstand step inputs, like a utility outage or something like that. Mm-hmm. Like you have that thermal buffer and that thermal inertia that can.

Help a system ride through a problem, whereas when you're dealing with liquid cooled applications, there's just so much more compute in such a smaller space and a, a, a step input, like a utility outage, you know, coupled with maybe something else that could go wrong, like it will have a much larger impact on Yeah, the

Dan Gentry: customer business.

All right. I hadn't heard that. That's, that's hot.

Charles Jelen: You nailed it. There you go. Alright, so you are the Chief Development Officer for Server Farm. Mm-hmm. Can you quickly give us who is Server Farm, what do you do and then what do you do specifically as the the CDO?

Sam Brown: Yeah. So Server Farm, uh, is a data center co-location company at its roots.

So we're developing data centers. We operate the facilities that we own and we lease 'em out to end users and then support whatever sort of facility level business needs they might have. How long have you been doing this? I'm going on my 15th year, so I've been here for a long time. Yeah.

Dan Gentry: So you kind of got to like see it all then being with it that long.

Sam Brown: Yeah, we uh, I definitely know where all the bodies are buried, but um, so maybe that's why keeping me around. Yeah, exactly.

Charles Jelen: Uh, one of the questions that we got a lot is site acquisition for some of these data centers. And we're gonna talk about power here, and I definitely wanna ask you about that, but outside of power availability, what are the hurdles to citing some of these data centers?

Because it feels like historically they've been clustered. You think of like Loudoun County and Virginia Silicon Valley, and it's just, you just keep building out that same hub, but it feels like it's changing. Now, some of that, I'm sure is driven by AI and the different workloads, but what goes into citing a data center when, when you look at it from your seat, other than power, we'll talk about power in a little bit.

Sam Brown: Sure. I mean, latency is always gonna be a driver. AI sort of, you know, neuter that a little bit. It's not quite as important just because of, you know, what AI actually is. It's not like cloud where you're providing services yet.

Charles Jelen: Right. Latency for the listener is physical proximity to other data centers so that you don't have a lag between any of the processes.

Is that a accurate

Sam Brown: Yeah, very well said. Yeah. So latency would be the other big driver. Outside of that, it's real estate development. I mean, you're looking for a friendly municipality. With I, you have to have tax incentives, uh, of some variety because it just wouldn't be market competitive if you didn't.

What does that mean when you say

Charles Jelen: tax incentive?

Sam Brown: Yeah, so most of the tier one and tier two data center markets are going to have a sales tax exemption that is geared towards data centers. And there are certain metrics and thresholds that the applicant would need to meet in order to qualify for that sales tax exemption.

So there's gonna be a certain number of jobs that you need to create and employees that you need to have at that site. They need to make a certain amount of money. They might vary here and there between states, but those are gonna be the key drivers and it's a huge number. I mean, a 60 megawatt data center is gonna have, you know, 200 to $250 million in equipment.

So you know, 10% sales tax or something like that. It moves the needle in terms of proforma, and then that's the smallest piece. Then you have the customers, they go and buy the servers. That it, it's probably an order of magnitude more than that 250 number I just said. Yeah. What makes a local municipality friendly?

Data centers do create quite a bit of tax revenue for a. The local economy. So big agrees in Silicon Valley has perfect roads and all of that infrastructure and new books and schools, it's data center revenue. It's a substantial amount of money. So they will court data centers to come in because they know it's gonna create construction jobs and it's multi-year and it's supporting that sort of digital infrastructure industry, good jobs, things like that.

So they want data centers for all of those reasons.

Dan Gentry: Yeah, it sounds like data centers are a good neighbor in your community.

Sam Brown: You know, we try to be, I think there's a lot of press right now about why they aren't good neighbors. I would just tell you, the server farm has been, we are really good stewards of the environment and we really do try to be fantastic neighbors, so we.

Do everything that the zoning regulations and local municipalities and federal regulations would require us to do from noise and emissions and things like that. But we don't use water when we're doing maintenance. We try to do it at times when. If we're near a residential neighborhood, we're gonna do it when they're not home.

Right. We're gonna do it when they're at school, at work so that, you know, they don't have a bunch of generators running it on a Saturday at eight in the morning or something like that.

Charles Jelen: Lot like the neighbor that runs their lawnmower. Yeah,

Sam Brown: exactly. Like that's just an unwritten rule. You don't do that. Yes.

Um, you don't run generators or lawnmowers before eight o'clock.

Charles Jelen: There you go. Yeah. Uh, you said like courting and, and that's a, that's an interesting one. Do areas, court developers to try to come develop something and so I asked that partially because I'm curious. I recently joined the Wisconsin Data Center Coalition, which is a coalition of.

Manufacturers in Wisconsin that are looking to bring data centers in because Wisconsin feels like it's behind in this build out. So are there coalitions like that, that are reaching out to you at Server Farm and say, Hey, we want you to come develop here, and is that even attractive for you? Or are you like, no, my clients want data centers in these three spots.

Thanks, but no thanks.

Sam Brown: Really good question. I think it's a little from column A and a little from column B, so the vast majority of our development is going to be in tier one markets, right? Where it's, it's established. I would say that it definitely happens. The gigawatt campus that we're looking at is absolutely one of those where they were courting a data center developer to come in.

But the vast majority of our development is gonna be in tier one markets where there's established customers. What are the tier one markets? I mean, Northern Virginia is the biggest. It is the, it's main and Maine in terms of data center demand. It is the largest market in the world, and unless they run outta power, it'll continue to to be the largest market in the world.

You have other ones. Dallas is huge. Atlanta's huge. Chicago's a big one. Ireland, Dublin is a, a massive market. London, Amsterdam. Those are all like really, really?

Charles Jelen: Serious data center markets. If you had to bet on the next tier one, who's coming in next?

Sam Brown: I think Charlotte is a perfect market for data center development.

I know some people are looking there, but they have infrastructure. It's close enough to Northern Virginia, so that if you needed to have like some spillover capacity, certainly could. I mean, right now these hyperscalers are building for their own account, like in Ohio, new Albany. The development there is absolutely mind-boggling.

Charles Jelen: Let's go to power. Power's power. Here we go. More power baby.

There I you. I've seen articles. It's like weekly. It's this trend of BYOP. Bring your own power, and you see people buying nuke plants and talking about small modular reactors and hooking up fuel cells. Is that real? Is the microgrid, large hyperscale, big co load data center?

Is that going to happen or is that. It is

Sam Brown: happening. It is. Alright. It is absolutely happening. What form the microgrid is gonna take, I think is still to be determined. You know, there's onsite, you know, natural gas reciprocating plants and turbines that definitely work. Uh, there are the SMR sort of approaches that.

I think are going pretty fast right now. Like there will be a, a use case for us all to evaluate with SMRs here in the very, very near future.

Charles Jelen: Oh, it sounds like you're under

Sam Brown: NDA, but I don't like it. No, no. It's, I should, yeah, that's right. I can't tell you. Part of our job is talking to peers and understanding what they're doing and how they're solving problems and microgrids are absolutely gonna be part of it.

I think the interesting piece. So the utilities are gonna be expanding as well, right? They have more red tape than a, you know, a data center developer's gonna have in terms of standing up generation assets. But they're going to do that. They're going to expand their ability to generate power and the reach of their transmission grid.

And then the question becomes, okay, do we pull these microgrids onto our transmission network? And then there's like a sleeving arrangement. Now we're. We have these generation assets as well, and I think that's gonna be the compelling thing in the future to understand how, again, being good neighbors, these data centers who are trying to go fast and solve these problems can actually solve national grid issues.

You see that a lot more in in Europe, but it will absolutely be part of the generation of power in the future for everybody.

Charles Jelen: Gotcha.

Sam Brown: What are you most excited about? We get to build like really cool. Pardon? My way was like, data centers are awesome.

Charles Jelen: Um, I was just, okay, so before you answer that question, we were just in a family trip in St.

Louis. We're looking at the arch and Dan goes, dude, we don't build anything like this anymore. And I was like, I think we do. You just don't see it. And I think it's data centers. I think that is like the new monument building of our generation. The scale you can't see the size you necessarily can't see, but it is impact to people.

Yeah, it's very there. Yeah.

Sam Brown: Yeah. Yeah. That is really insightful. I mean, if. If we spent a little bit more money making 'em look nice, like you could probably say it

Charles Jelen: kind of is. You're probably right. You'd have the four corners of the earth coming to see the largest data center in the world. You know what I mean?

Totally. We could drive this, you know, it's go architectural beauty. I would

Sam Brown: show my kids, you've driven to see like the largest ball of yarn, like of course you'd go see the largest data.

Charles Jelen: Yes. Alright, well hey, you include that in your next pitch for a gigawatt. Yeah, absolutely. I want like a data

Dan Gentry: center that looks like the pantheon or something.

Charles Jelen: Yeah.

Sam Brown: It is so fun to build these things. You know, when you're dealing with data centers, you're just dealing with a, like a higher class of criminal. It's, it's just, you know what I mean? Like, it's just a more sophisticated workforce. It's a more sophisticated construction team. Design team. You know, when you come in and you're talking to municipalities, they understand that it's a data center and they know that you're gonna have your stuff together and they are asking good questions.

I, I don't know. I. I couldn't build a school. It's super important, but the pace and the scale and the sophistication, just data centers are awesome. Data centers are rock.

Charles Jelen: It's the best. Yeah. Alright, last question. If you had a magic wand, you could change one thing in the data center space, what would it be?

Sam Brown: I, that's a great question. I think that there's an intellectually dishonest conversation that happens with. Customers and developers all the time about schedule. People think that you can go faster than say the laws of physics can accommodate. That's the piece that it gets me. They want you to go as fast as possible, work three shifts, work seven days a week, get as many electricians as you can get.

All these people ramped up, but then they want you to be as safe as possible. We want maximum safety and, and zero risk. Zero risk. Like the quality has to be good. I want the same expertise with the day shift. Electricians as the night shift electrician, you have to have maximum productivity all the time, seven days a week.

And it's not possible. Like, why are we even talking about it? Let's set the, the standard for pace and. Just go

Charles Jelen: forward with it. But yeah, and I'm sure you never get any faulty lead times from OEMs on chillers. I'm sure that never happens. No, no, no. Never.

Sam Brown: No, no. It's uh uh, everyone does as good as they can, as long as you step up to the flight and try to help solve a problem.

You're good. In my book. Love it.

Charles Jelen: That was great. Cool. That was good. No, fellas. I appreciate it. This was fun. Sam. Thank you so much for coming. That was an awesome conversation. Up next, Dan's going back inside the factory. Stay tuned.

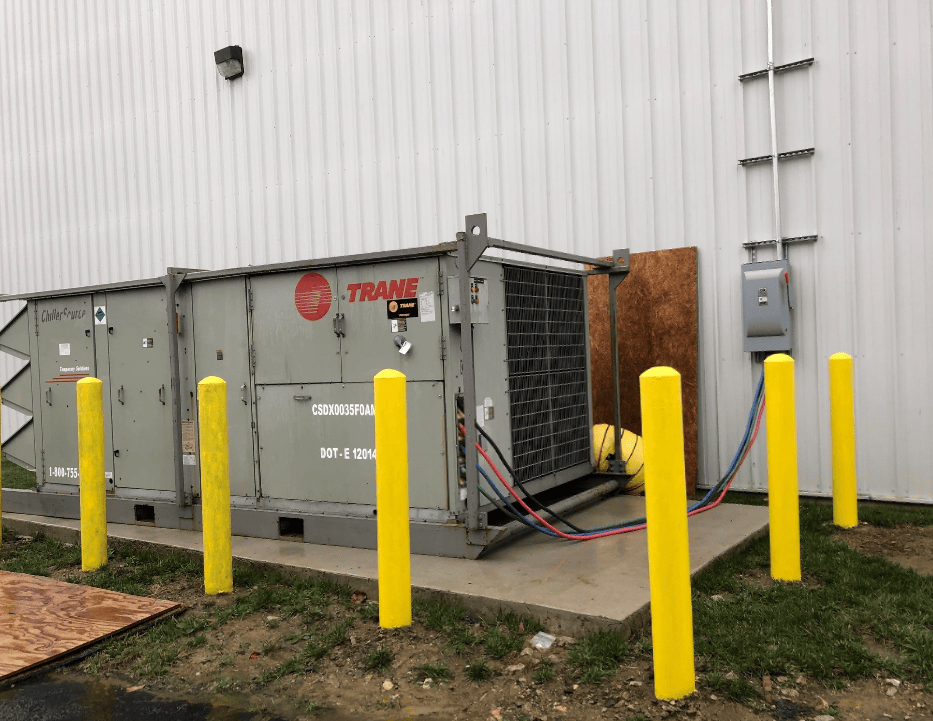

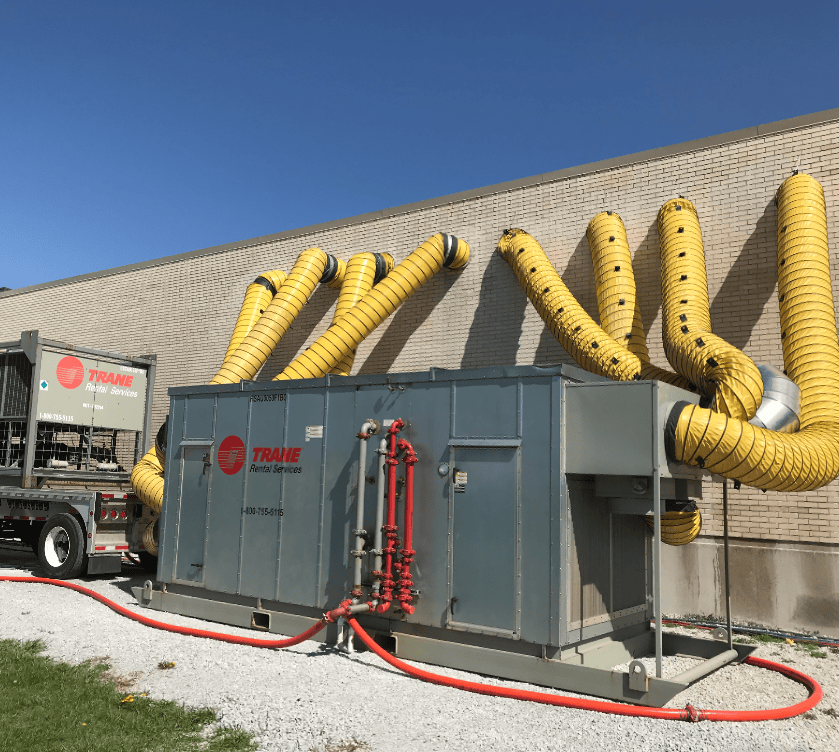

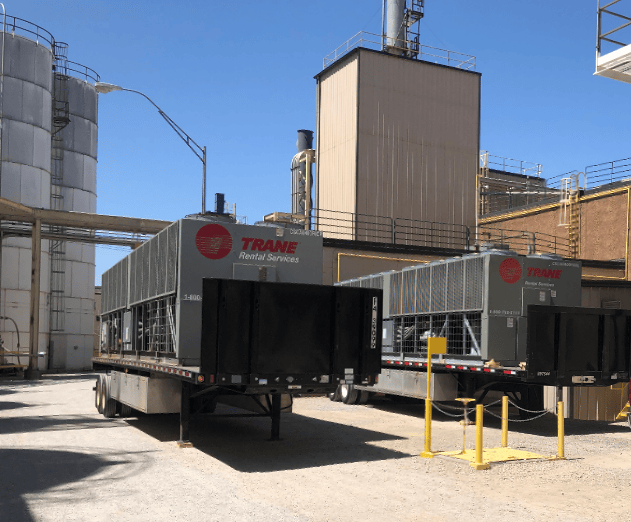

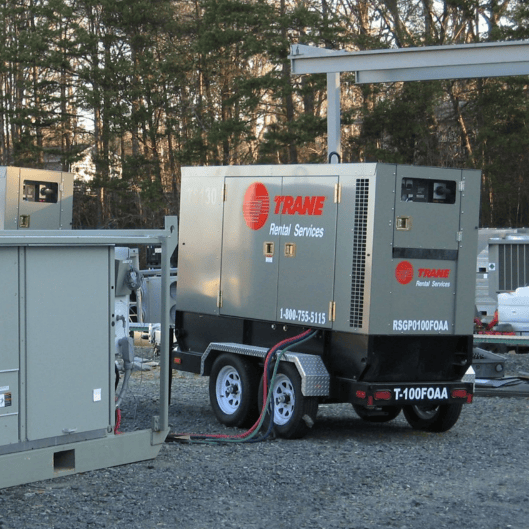

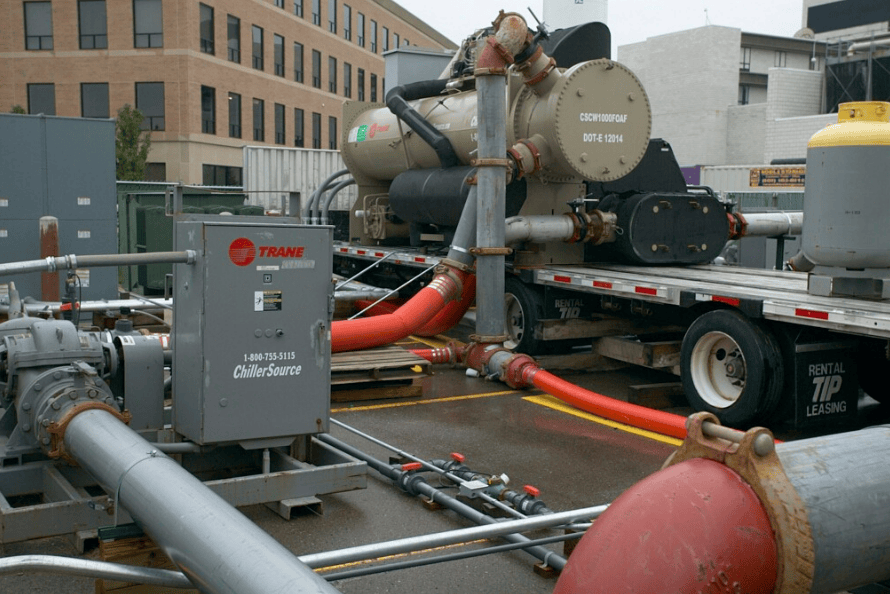

Danno. Yeah. What's available 24 7 365 to keep your operations up and running. Oh, you know, it's all gotta be ball bearings these days. Well, that's a good line, but I'm talking about train rental services.

Dan Gentry: Oh yeah. Whether you're dealing with seasonal demand, emergency needs, planned expansion, or those annoying production gaps, train rental services has

Charles Jelen: got you covered.

They provide customized solutions to keep your operations run in smoothly and avoid any costly downtime. The best part, they're available 24 7 365. And of course, it's

Dan Gentry: easy to connect with them too. Check out trane.com/rentals to learn more today.

Charles Jelen: All right, listener, it's time for another installment of Dan Inside the factory, or whatever we're gonna call it in the future here. This was inspired by Gary Hill, who emailed us asking if we could get up close and personal to the train factories. And boy did Dan ever deliver. Oh. Oh yeah. It's a good time.

So let us know if there's specifically anything that you wanna see inside the factory, inside our labs, inside our offices. Send it over to Cool air.hot takes@trane.com.

Dan Gentry: So, as you know, last week we had, uh, ESD on and we walked through the chiller manufacturing facility to check out what that kinda looks like.

Uh, this week we're gonna head over into the lab where product development and testing gets done, and we're gonna go talk to one of the technicians that operates and test these units and see what that work looks like and see what they're up to. So. Here we go. Check it out. Alright, listener, we're uh, back on assignment again.

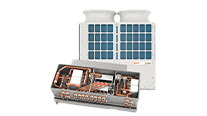

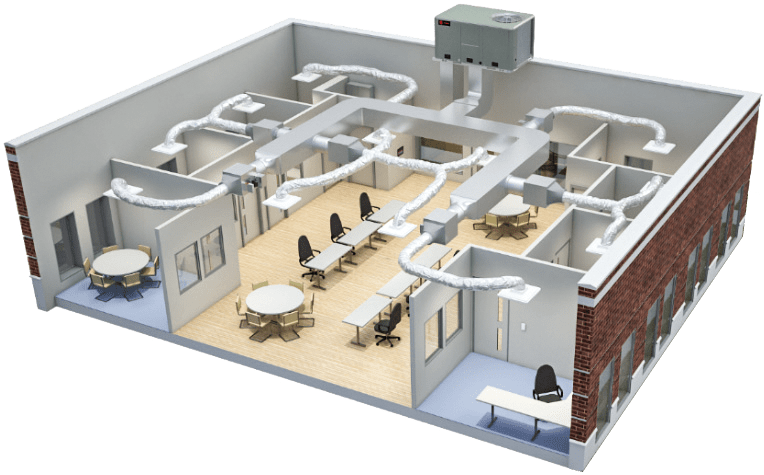

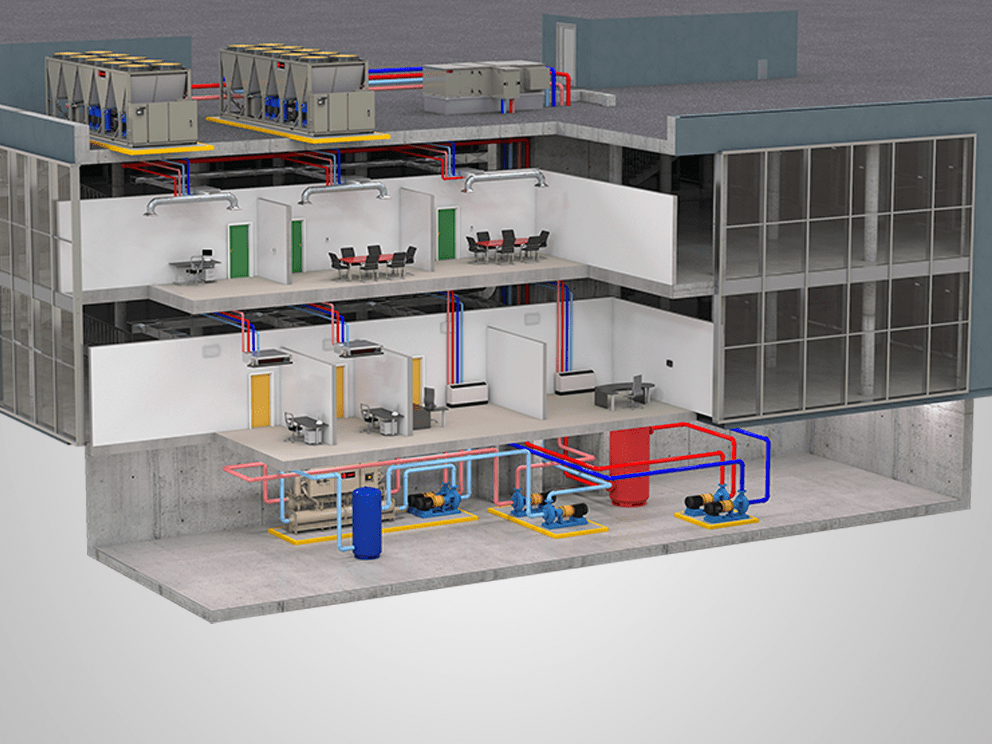

I'm outta one of the factories again. This time we're gonna be looking at a CDU, uh, unit, which is a cooling distribution unit. I'm out here with Scott Neiman Scott, why don't you tell us who you are and what we're looking at.

VO: Thanks, Dan. My name's Scott Neiman. I'm a. Thermal systems development engineer and we're looking at a CDU or coolant distribution unit, and this is essentially a tertiary pumping unit allowing us to connect our, uh, large industrial scale cooling abilities with our chillers and connect them to the, uh, technology side of a data center.

We essentially the server racks inside of a data center,

Dan Gentry: so. One side of this unit will be fed by chillers, runs through a heat exchanger in the unit, and on the other end, cold water is being provided to the white space in the data center, the computers, all those cooling components.

VO: Exactly. We have two sets of pumps in here in parallel, so it offers some redundancy and essentially that heat is transferred over onto the facility side and kicked out of the facility through our train chillers.

Dan Gentry: And those pumps are redundant, you said? One's operating one's in standby.

VO: Yeah, almost always we have one operating one on standby. Sometimes we'll set it into a a duty mode, so one pump will run for a set amount of hours, and then the other one will run so that you can get equal amount of run times on 'em, or you'll just have one in standby so that if it ever, ever fails, you can switch over to the other one.

Dan Gentry: Okay, cool. Next thing, this is a really beefy unit. Just when you open up this cabinet and look at it, I see stainless steel valves. Fittings, all that kind of stuff. This looks like I said heavy duty. Why? Why is that?

VO: It is heavy duty. I mean, on one side you're saying, uh, we're on the industrial scale of things.

The regular stuff that we deal with day in and day out. On the other side of things, we're talking data centers, really a high end technology, and they're looking for. Really clean, really, uh, contamination, free cooling on their side. They don't want any sort of contamination. Getting into the data center and potentially destroying millions of dollars worth of sensitive technology

Dan Gentry: makes a lot of sense.

So you wanna have a really robust. Cooling system because what you're cooling is so valuable.

VO: Exactly, exactly. We got a lot riding on these things, so we need to make sure we get this right. What kind of capacity is this? The one we're looking at right now is a one megawatt unit, but we do have options to go up to two and a half megawatts and you can combine them together to get a 10 megawatt, 10 modular solution.

Okay,

Dan Gentry: cool. And just for the. Audience. I would say this would be the size of like a large commercial refrigerator. Yeah. Maybe if you took one of these and in some context,

VO: yeah. I'd say that a large commercial refrigerator, essentially the large server racks, if you think, yeah, a large server farm. This kind of fits that same form fact.

Awesome. Cool. Well. Thank you for your time. Absolutely. Okay.

Charles Jelen: Well, Danny Boy, another good installment of Dan Inside the Factory. Up next, we've got stat of the day.

Dan Gentry: Here

Charles Jelen: come Joe of the day. Sta of the day. Alright, listener, stat of the day. Childcare Costs by US State. So this is from, the data is from Wallet Hub. So what we're looking at is, or what we're talking about is the median percentage of income spent on childcare in the us.

So the median across the US is about 9%.

Dan Gentry: 9%. Okay.

Charles Jelen: So we're gonna talk about the top states and the bottom states. So where's it the cheapest? Where is it the most expensive? You got what? What? Gimme your top. What do you think? I

Dan Gentry: mean, I

Charles Jelen: think the

Dan Gentry: most expensive would be like Northeast States. I'm gonna think like New York.

Mm, okay. Massachusetts. And then I'd probably go hop on an airplane out to California. What's the least, least expensive? Yeah, most affordable. Uh, most affordable, I would say like the Midwest or the south.

Charles Jelen: Yeah. Oh, you nailed, you nailed that one. All right, let's do this. So Hawaii tops the list where families spend 13.5% of their income on childcare.

So the wasn't on my radar. So the median is 9%. Hawaii's at 13 point a half, oof. Vermont at 13.2, Oregon 12.9, and Washington State at 12.6. Hmm. I don't know if I would've guessed those, to your point. The other ones aren't far behind. Massachusetts is 12.4 in California. 12.3. Alright. Most affordable. Most affordable.

Where? Where you wanna live, if you want lower cost. Mm-hmm. Childcare, South Dakota. 6.7%. That is the lowest. All right. Other ones include Mississippi 7.7, South Carolina 7.8, Alabama 7.9.

Dan Gentry: Okay. My Mississippi, Alabama. I'm gonna call South Dakota close enough to the Midwest. Oh, I, I

Charles Jelen: definitely

Dan Gentry: think so.

Charles Jelen: Thanks for listening to this episode of Cool Air Hot Takes. Thank you so much to Sam Brown from Server Farm for coming out and talking to us today. Thank you to the cool Air Hot Takes production team. Tip of the cap to Elena, Juan Yee, Bailey Ainsley, Katie and Christie. You guys are awesome.

Dan Gentry: And of course, send us questions and hot takes by leaving us a comment on Spotify or YouTube leaving a review on Apple.

Or of course, dropping us a message@coolair.hot takes@trane.com. Don't forget, you can also leave us a rating wherever you listen. As always, five stars, only please. Until next time, stay cool. And keep those takes hot.