Yes. Trane designs HVAC systems to meet cleanroom standards, including particle control, pressure differentials, and tight temperature/humidity tolerances. Our solutions are tailored to your classification level and cleanroom zone needs.

Overview

Meeting the evolving complex HVAC demands of high-tech manufacturing.

Innovation depends on stability. Trane helps advanced manufacturers balance productivity with energy goals by integrating precise environmental control, collaborative design, and sustainable system strategies for long-term performance.

-

Precision Engineering

We deliver precise, repeatable control for temperature, humidity, and airflow. Our HVAC systems support cleanroom performance and process stability in semiconductor fabs and OSATs, EV assembly, battery and solar manufacturing facilities.

-

Collaborative Partnership

Trane works alongside your design and construction teams from day one. Our consultative approach ensures every system is engineered for reliability, efficiency, and lifecycle value.

-

Sustainable Innovation

Trane’s decarbonization and heat-recovery technologies help manufacturers reach sustainability goals without sacrificing performance. Smarter systems, lower emissions, and measurable results are built into every project.

Solutions & Services

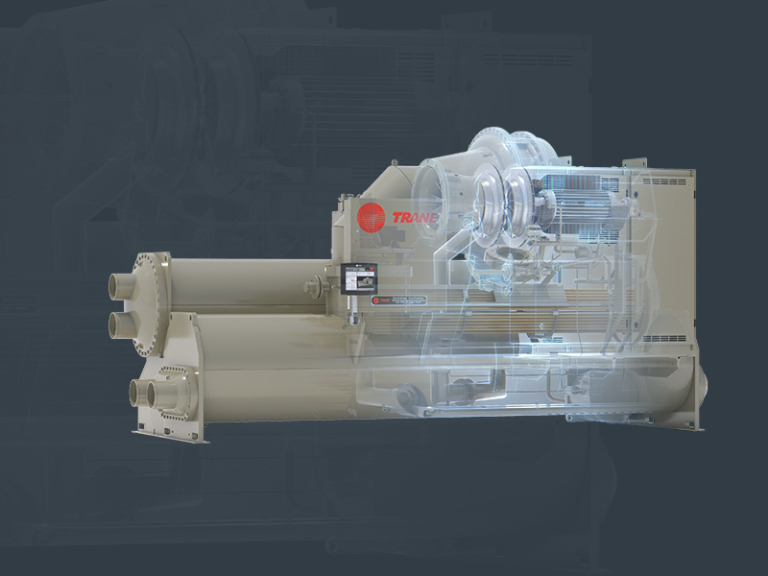

HVAC and process cooling solutions engineered for precision and sustainability.

Maintain exact temperature, humidity, and pressure control with solutions designed for cleanrooms and process-critical equipment. Trane engineers integrated HVAC and process cooling systems that help protect yield, maintain compliance, and reduce energy use even in the most demanding environments.

-

Maintain critical environments for advanced manufacturing facilities such as semiconductor fabs, EV assembly and battery, and solar manufacturing. Trane’s cleanroom HVAC systems use advanced filtration, humidity control, and pressure management to eliminate contaminants and maintain ultra-stable temperature and humidity conditions for consistent product yield and reliability.

Customer Stories

Learn how we've helped high-tech industry customers like you.

-

-

Brookfield Infrastructure Partners Data Center: Energy-Efficient Cooling and Cost Savings

Upgrades to Cyxtera’s chiller plant and pumping system controls led to a decrease in energy consumption of 0.7 kW/ton, resulting in over $2,100,000 in annual energy cost savings.

Related Products

Related Articles

-

Waste Heat Recovery for Data Centers

Esti Tierney, Product Manager - Centrifugal Chillers for Trane, explores how to give purpose to all the power and energy we already have and turn it into a strategic advantage.

FAQs

Your questions about HVAC for high-tech manufacturing, answered.

Ideally, Trane is brought in during pre-construction, during the design development. Early collaboration helps align HVAC performance with process requirements, avoid redesign, and ensure efficient system integration from day one.

Semiconductor fabs and battery gigafactories require ultra-tight temperature and humidity control, contamination prevention, redundancy for uptime, and often large-scale process cooling. Trane engineers solutions that support tool-level performance and yield protection.

We offer electrification strategies, heat recovery, thermal energy storage, and energy contracting. These enable facilities to reduce carbon emissions without sacrificing process stability, all aligned with ESG reporting requirements.

Strategies to reduce HVAC energy intensity in cleanroom environments include variable airflow control, heat recovery, chiller plant optimization, and right-sizing based on tool load. Trane’s controls and analytics help continuously optimize energy use without impacting classification or uptime.