There are a variety of systems that can serve indoor agricultural spaces and commercial grow rooms. Each has its own set of advantages. Consideration must be given to the type of system, system configuration, installation and system control to help support reliable operation in all conditions.

Indoor Agriculture Systems

Overview

A technology-based approach to indoor agricultural HVAC.

Trane helps specify systems that are designed to precisely control the ideal indoor agriculture environment to enhance yield.

-

Environmental Control

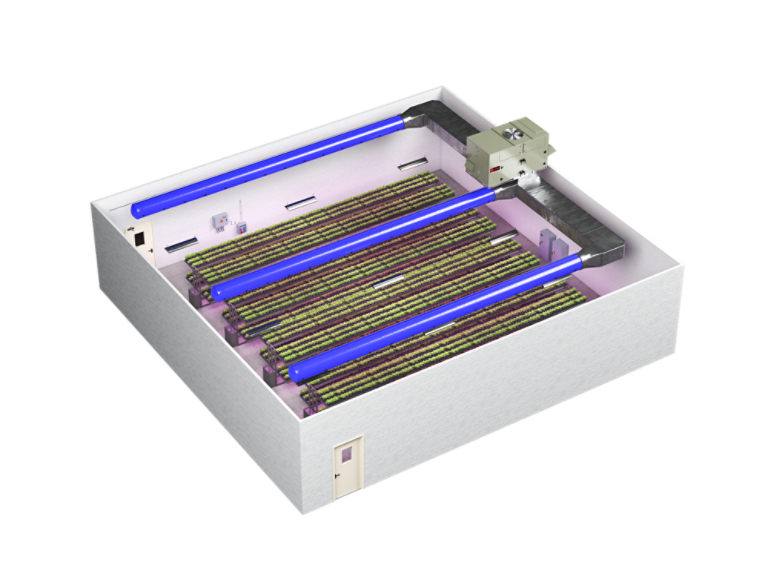

Trane indoor agriculture systems manage lighting, temperature, humidity, and CO2 levels to support consistent growth cycles. Simplify management of proprietary growing processes.

-

Energy Efficiency

Lower your production expenses and enhance efficiency by maintaining ideal growing climates 24/7. Trane indoor agriculture systems utilize efficient lights, automated control systems, and scheduling strategies to save energy.

-

Advanced Technology

Trane provides purpose-built indoor agriculture systems, air-handling units, and chilled water systems, all combined with advanced controls for monitoring, troubleshooting, and insights to help improve harvests.

Product Information

-

Trane Thrive is a packaged rooftop unit designed specifically to meet precise dehumidification and temperature requirements for indoor grow rooms.

-

Air-Cooled Chillers and Heat Pumps

Trane’s air-cooled chillers and heat pumps are designed for customizable efficiency, sustainability, and cost-effective thermal management in commercial buildings. -

A diverse portfolio of water-cooled chillers, featuring centrifugal and helical rotary screw technologies, ranging from 80 tons to over 4,000 tons.

-

Performance Climate Changer® Air Handlers

Trane® Performance Climate Changer® air handlers can help HVAC systems improve efficiency and indoor air quality while reducing maintenance requirements.

Trane Engineers Newsletter LIVE

Indoor Agriculture HVAC System Design Considerations

FAQs

Your questions about indoor agriculture HVAC systems, answered.

Indoor agriculture can be an energy-intensive operation. During the “daytime” mode when grow lights are on, indoor agriculture HVAC systems must provide enough cooling to offset the sensible loads (likely from grow lights and some envelope loads). At the same time, the systems must also offset the space latent loads from plant evapotranspiration which requires dehumidification.

To maintain space temperature and humidity for indoor farms, indoor agriculture HVAC systems will very likely need to be equipped with both temperature and humidity control.

During the “nighttime” mode when grow lights are turned off, systems often need to provide dehumidification to offset some space latent loads from the plants, but there is little sensible cooling to offset. In fact, there may be times when the space requires both dehumidification to offset the plant’s water vapor contribution and heat to offset the cooling effect from the plants.

When dealing with commercial grow rooms or indoor farming, several HVAC considerations arise. Plants need a variety of nutrients, minerals, vitamins, water, carbon dioxide, and oxygen. A system or enterprise control system can be used to integrate lighting, irrigation, fertilization, and HVAC operation.

The procedure for determining the proper supply air conditions—dry bulb temperature and humidity ratio— may be different due to the fact that the load can be dominated by plant latent loads. As a result, the proper supply air conditions may not conform to traditional comfort cooling methods. HVAC design and analysis tools, like TRACE® 3D Plus™ can help with this.

The use of a controlled environment permits the growers and operators to determine when plants are illuminated for the “daytime” period when grow lights are on. In those buildings with multiple, separated growing spaces, operators may consider staggering the “daytime” periods for several reasons including reduced peak load, electrical demand and load swings.

Air filtration helps HVAC components remain relatively clean and helps keep foreign contaminants and particles out of the growing environment.

Resources & Insights

Explore indoor agriculture system resources.

-

-

6 Ways for Indoor Agriculture to Grow Sustainability

Precisely maintained indoor environments make indoor growing operations highly efficient. They consume up to 95% less water, use less fertilizer and pesticide and are hundreds of times more productive per square foot compared to traditional farming methods. And growers don’t need to worry about Mother Nature spoiling the harvest. -

Designing an HVAC Systen When Your Building Occupants are Green

Green plants, such as lettuce, kale, basil, and other crops, are being grown by indoor agriculture producers around the world. Maintaining an optimal environment is just as important when plants are grown indoors as when they are outside. -

Nevada Looks toward Electricity Deregulation Vote

Nationally, the trend of power deregulation seems to have largely stabilized. While there are some occasional efforts in states like Ohio or Michigan to re-regulate, these rarely make it past the introduction of a bill or speculation on the part of a utility spokesperson. Similarly, few states seem to be interested in deregulating (or in the case of California and Michigan, further deregulating) their power sector.