- 10-year heat exchanger warranty standard on all units

- Two-point suspension on propeller fan unit heaters

- High-efficiency models available; offer 20 to 25 percent annual fuel savings over conventional gravity-vented models

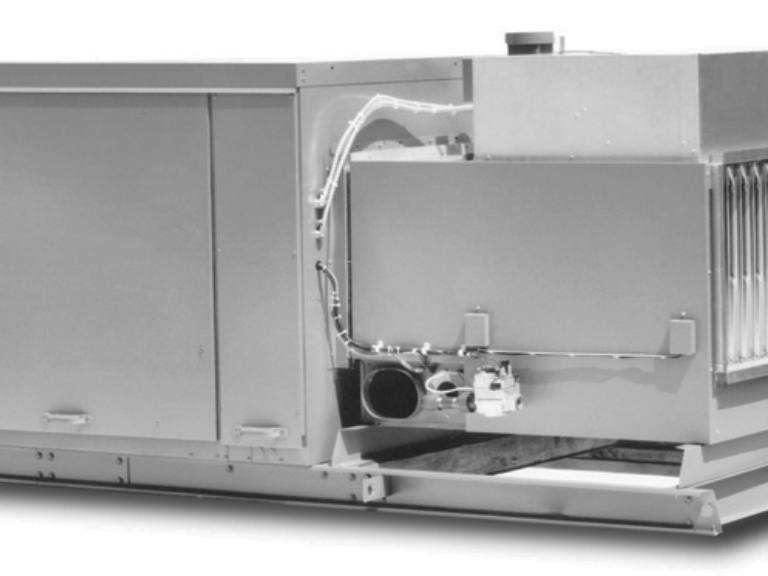

- Lightweight, rugged, compact design is fully accessible for easy installation and maintenance

- Optional explosion proof motors

Trane Hydronic Unit Heaters

Overview

Explore the benefits of hydronic unit heaters.

Uniform heating for large open areas—such as warehouses, factories and showrooms—without extensive duct systems. Easy, budget-conscience installation.

- 38 models, 8 to 705 MBh

- Model P available in 15 sizes to 705 MBh

- Model S available in 23 sizes to 360 MBh

- Available in steam or hot water

- ETL Certified

-

Flexible

The line of Trane Hydronic Units Heaters is built from two models: Model S and Model P. The Model S is a horizontal propeller heater of unusually compact size and low weight. The Model P is two units in one. A vertical heater which easily converts to a low final air temperature unit.

-

Unmatched Array of Options

The Trane line of Hydronic Unit Heaters features 26 models and 130 selections, an array of options that are unmatched in the industry. Model P available in 15 sizes to 705 MBh and Model S available in 16 sizes to 400 MBh.

-

Streamlined and Budget-Conscience Installation

The lightweight, rugged, compact design of Trane Hydronic Unit Heaters is fully accessible for easy, cost-effective installation and maintenance.

-

High-Efficiency Models Available

The Trane Hydronic Unit Heater line also features high efficiency options, to help with sustainability, budgetary, or efficiency goals. These units offer 20 to 25 percent annual fuel savings over conventional gravity-vented models.

Product Information

- 38 models, 8 to 705 MBh

- Model P available in 15 sizes to 705 MBh

- Model S available in 23 sizes to 360 MBh

Installation Operation Maintenance (IOMs)

FAQs

Your questions about hydronic unit heaters, answered.

A hydronic unit heater is a heating system that uses hot water or steam from a boiler or heat pump to generate heat, which is then distributed through a fan to warm a specific area.

Sizing a hydronic unit heater involves calculating the heating requirements of your space based on factors such as square footage, insulation quality, and local climate conditions. Our account managers can assist you in this process using our advanced selection software.

Hydronic unit heaters offer efficient and consistent heating, are highly durable, and can be integrated with existing hydronic heating systems, making them ideal for various commercial and industrial applications.

A hydronic unit heater works by circulating hot water or steam from a boiler or heat pump through a heat exchanger. A fan blows air over the heat exchanger, distributing warm air evenly throughout the space.

The primary difference is the heat source: gas unit heaters burn natural gas or propane to generate heat, while hydronic unit heaters use hot water or steam from a boiler or heat pump. This makes hydronic heaters ideal for buildings with existing hydronic heating systems.