Glossary

Heat Pump Chiller

Discover the reason heat pump chillers are becoming more widely used. Learn about their operation and advantages.

Selecting a language changes the language and content on the Trane site.

Trane ComfortSite is an extranet site designed to save you time. With your secure login, you can:

This is the login for Trane® Connect™ and other Trane® commercial applications. Trane® Connect™ is our secure, cloud-based customer portal to access your building systems to remotely monitor and manage building systems, and conduct routine maintenance.

Latin America

Europe

Asia Pacific

Glossary

Discover the reason heat pump chillers are becoming more widely used. Learn about their operation and advantages.

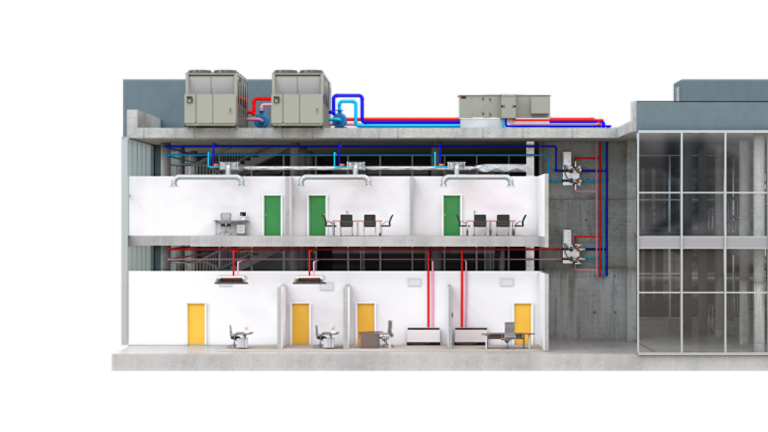

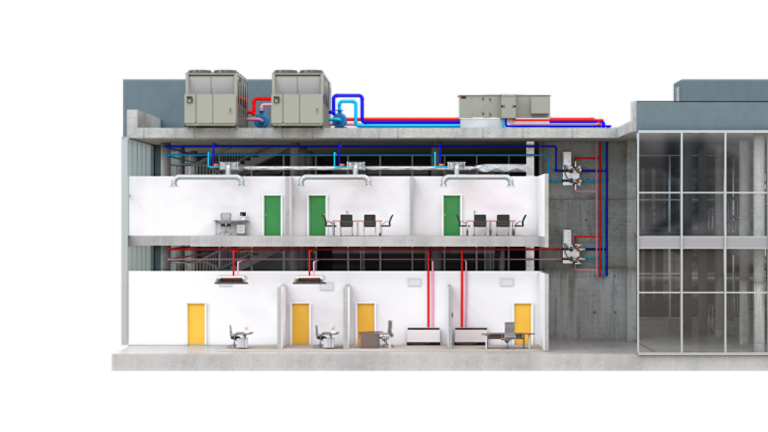

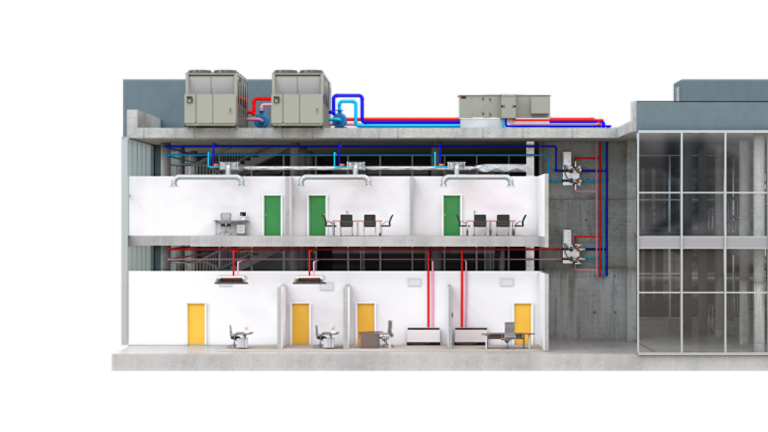

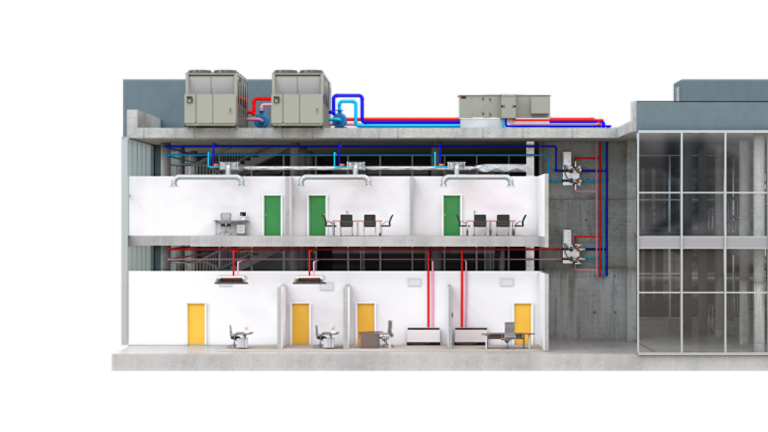

A heat pump chiller is a specialized HVAC system that provides heating and cooling by sourcing heat from water, air, or other fluids and transferring it to a fluid, utilizing the same basic components as a traditional chiller but with heating control capabilities. These systems are increasingly used in large commercial applications due to their energy efficiency and versatility.

Heat pump chillers incorporate the same basic components as standard chillers and air conditioners, but with one added piece — the ability to heat which is sometimes achieved with the use of a reversing valve. Here are the components of a heat pump chiller and their functions:

Heat pump chillers transfer heat rather than generate it. They extract heat from air, water, or the ground to heat spaces.

The pros outweigh the cons with heat pump chillers in most cases, but to ensure you choose the best system for your building and its location, talk to one of our experts in your area.

Resources for Heat Pump Chillers

To learn more about how our heat pump chiller systems can help your business save energy and long-term costs and improve its sustainability, contact your local Trane representative today.