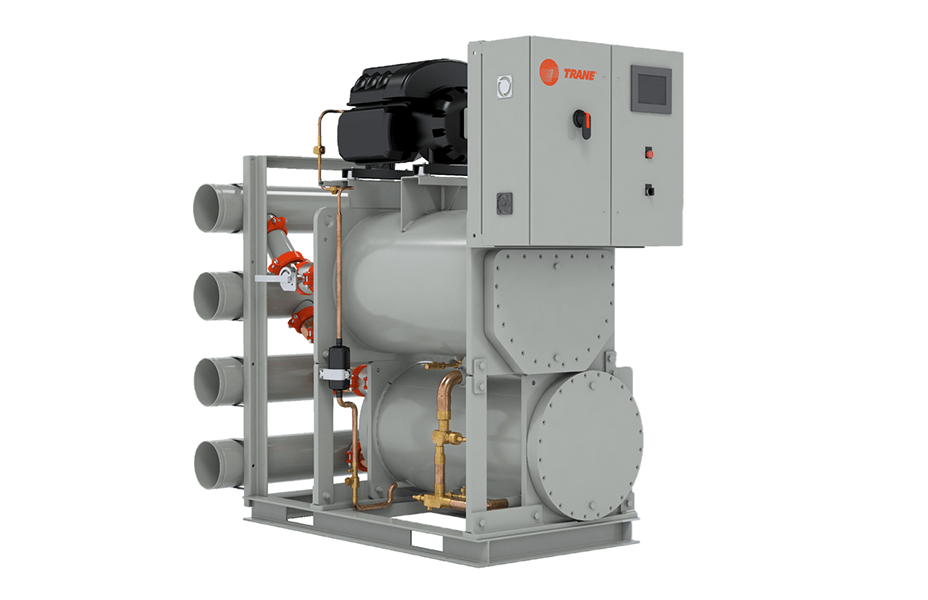

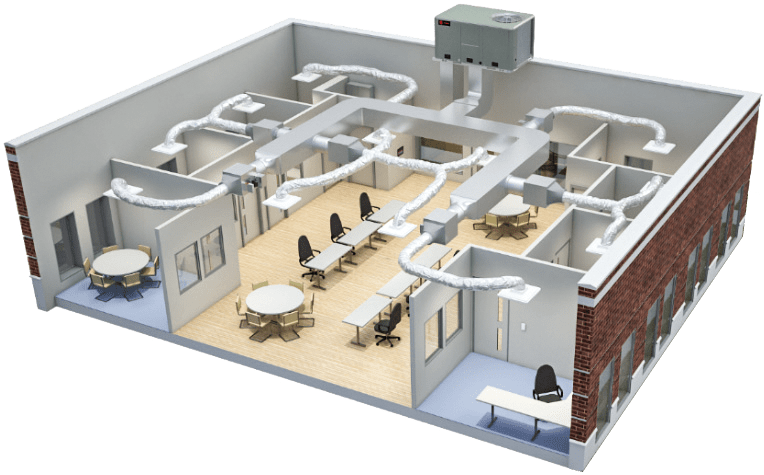

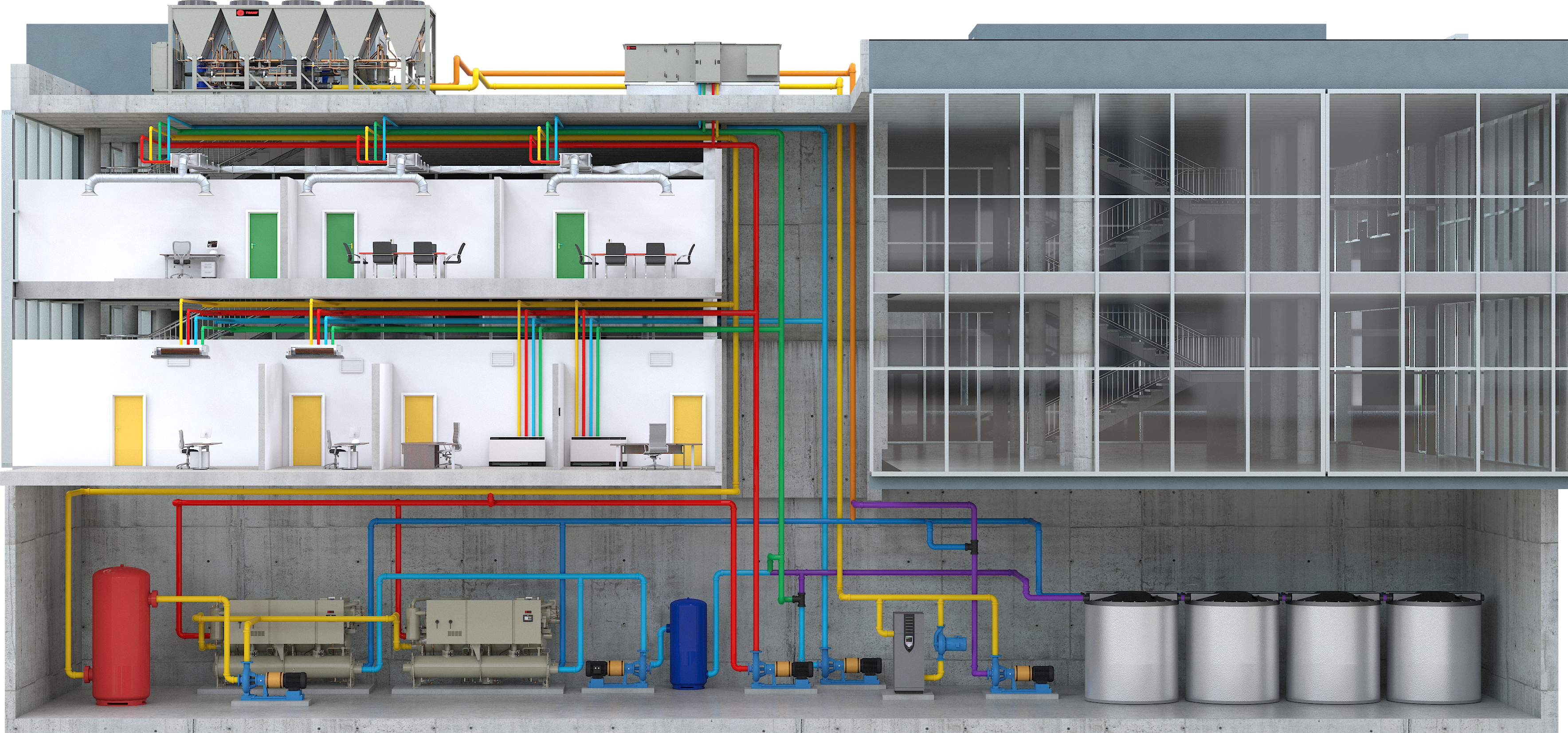

Last year, Trane made it easier to specify commercial heat pump solutions for hydronic systems by introducing our Comprehensive Chiller-Heater Systems. The first system in this series, the Air-to-Water Heat Pump System, brought together an engineered combination of air-to-water heat pumps, chiller-heaters and controls. For many buildings, those three components alone can provide a reliable and efficient replacement for fossil fuel heating that helps owners achieve building electrification and avoid carbon penalties.

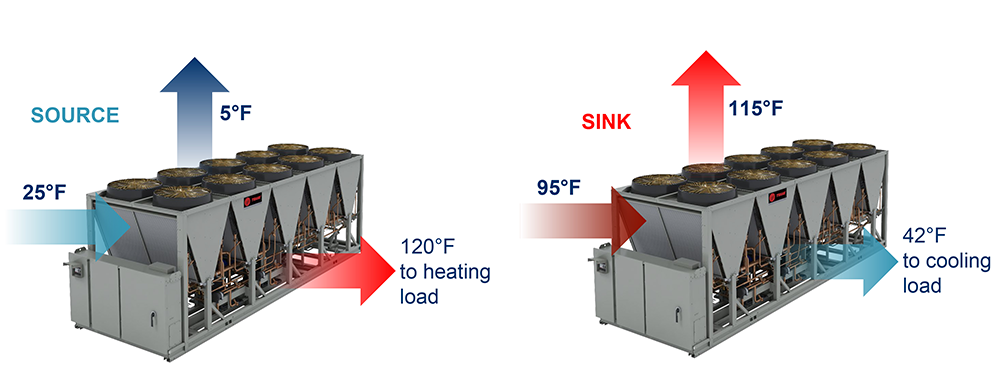

It is an amazing solution for many applications. Yet, it may not be a fit for some buildings. First, most urban buildings don’t have enough roof space available to accommodate big air-to-water heat pumps—in multiple. Second, air-to-water heat pumps have diminishing capacity and lower leaving water temperatures at low outdoor ambient temperatures. And finally, defrost cycles must be accounted for when calculating air-to-water heat pump capacity.

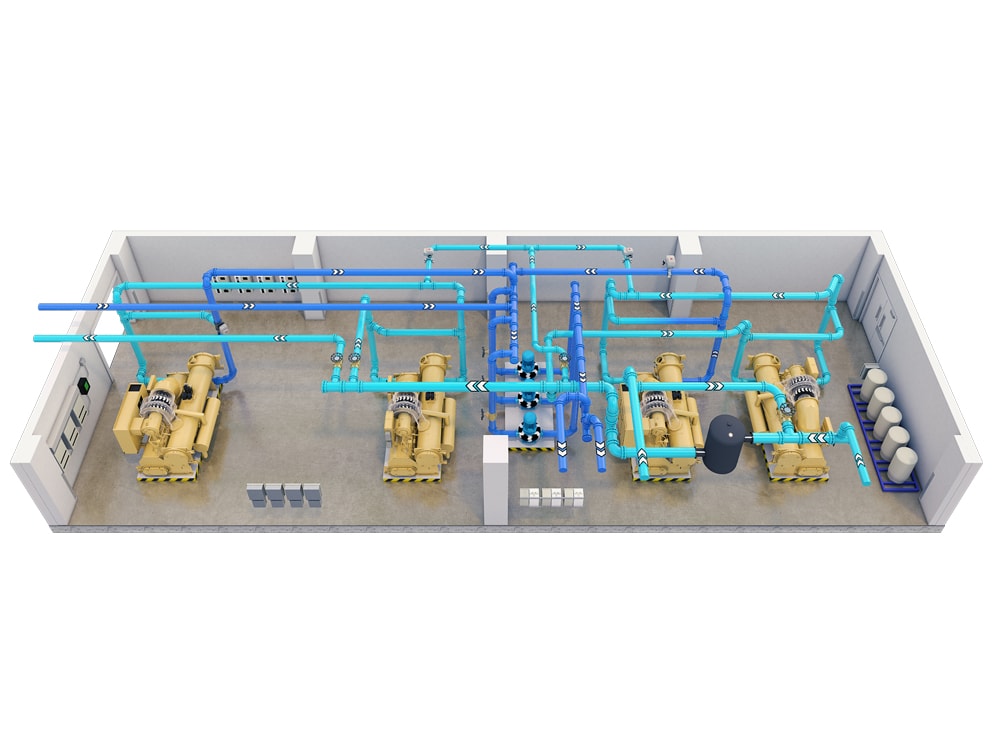

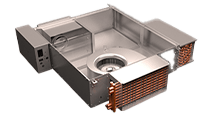

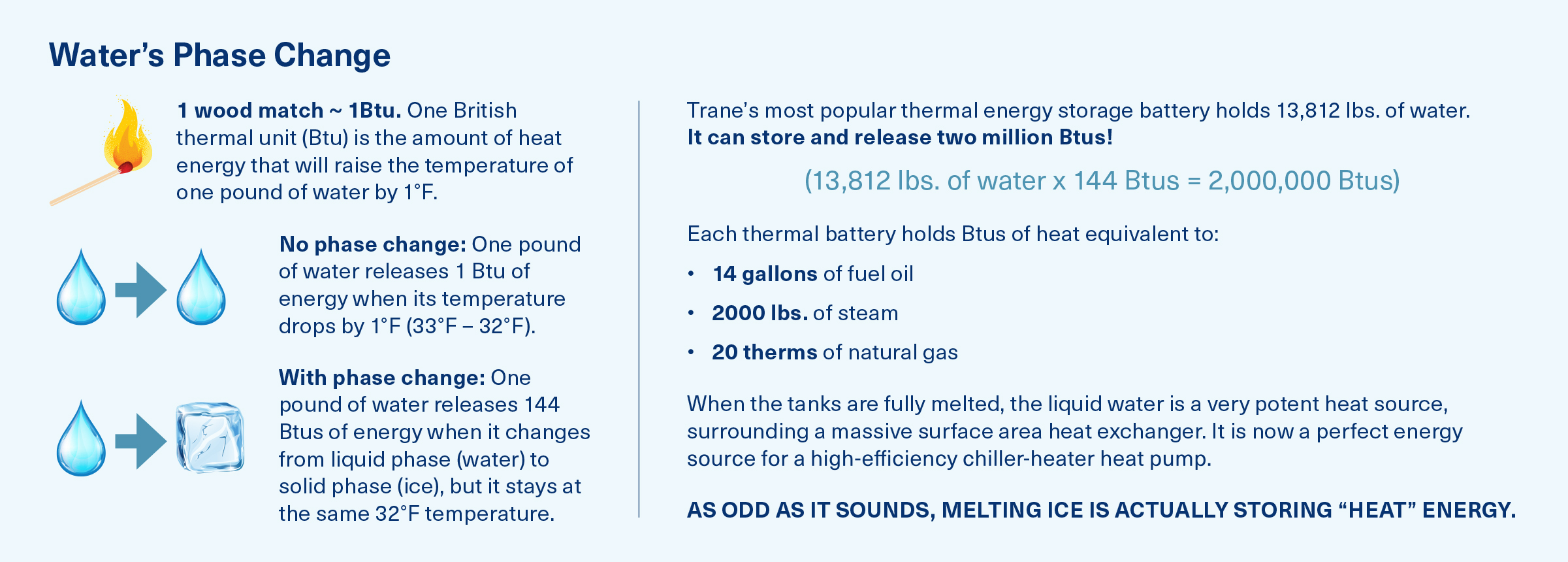

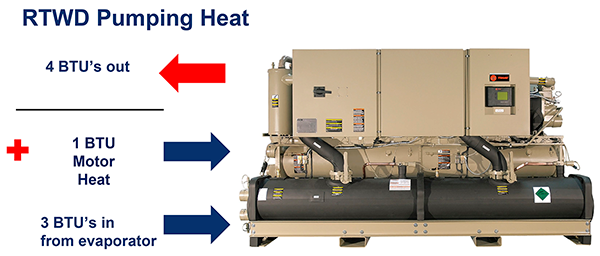

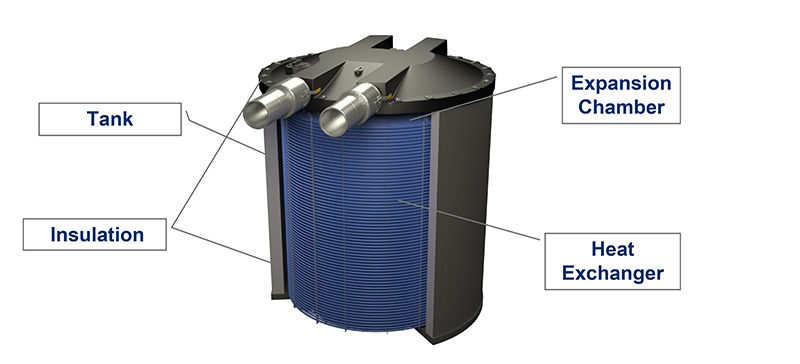

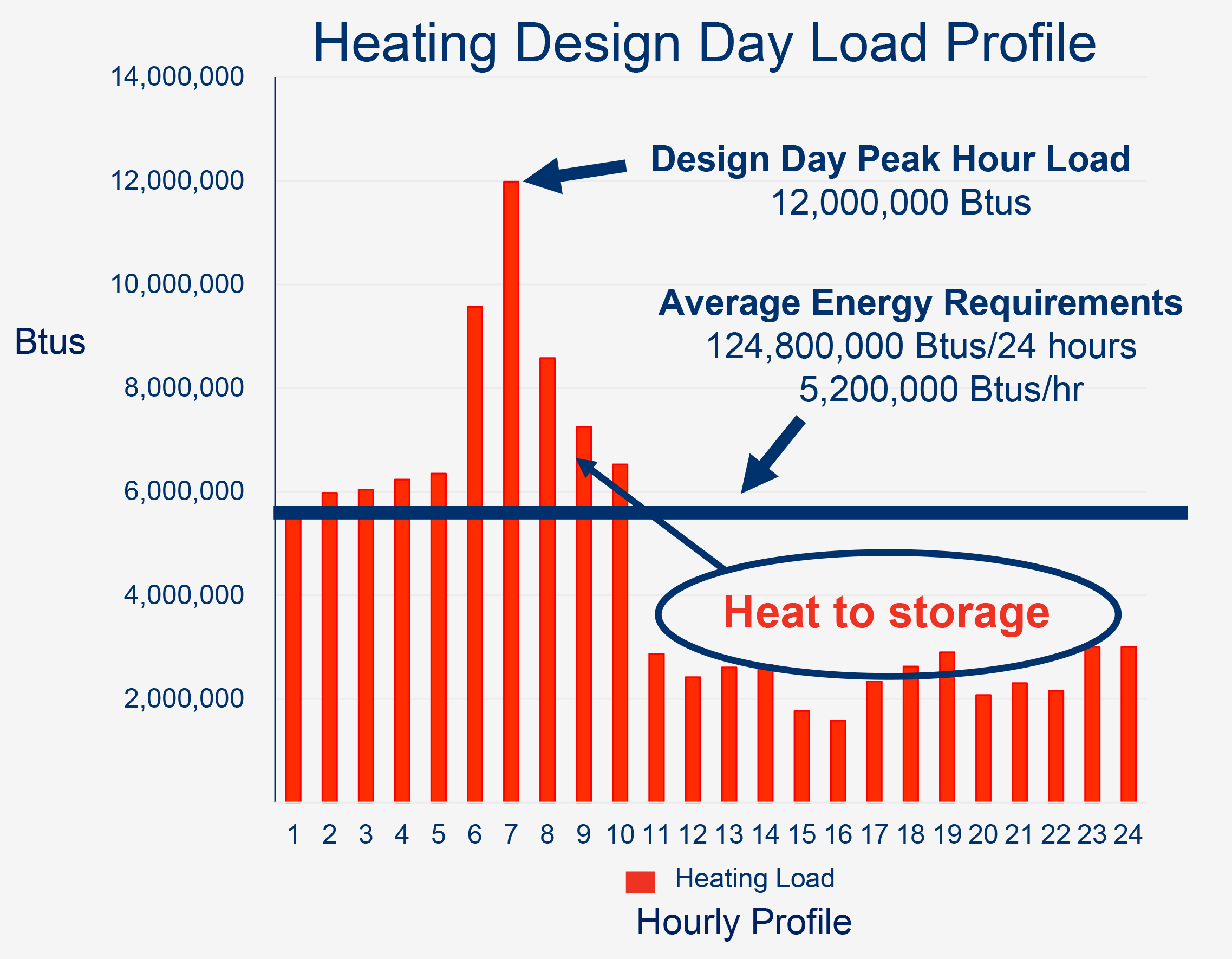

The solution to these issues is ingenious, but the premise is as simple as a high school physics lesson: Heating with ice. Adding thermal energy storage to the Air-to-Water Heat Pump System overcomes these barriers, so more buildings can join the decarbonization movement.