Turnkey solutions reduce product loss, generate $350,000 savings • Remington, Indiana

Solae, LLC, a world-leading producer of soy-based ingredients for food manufacturing companies worldwide, was challenged by high humidity levels and rising energy costs at its production and packaging plant in Remington, Indiana. To remedy the situation, Solae enlisted Trane Turnkey Contracting Services.

Challenge

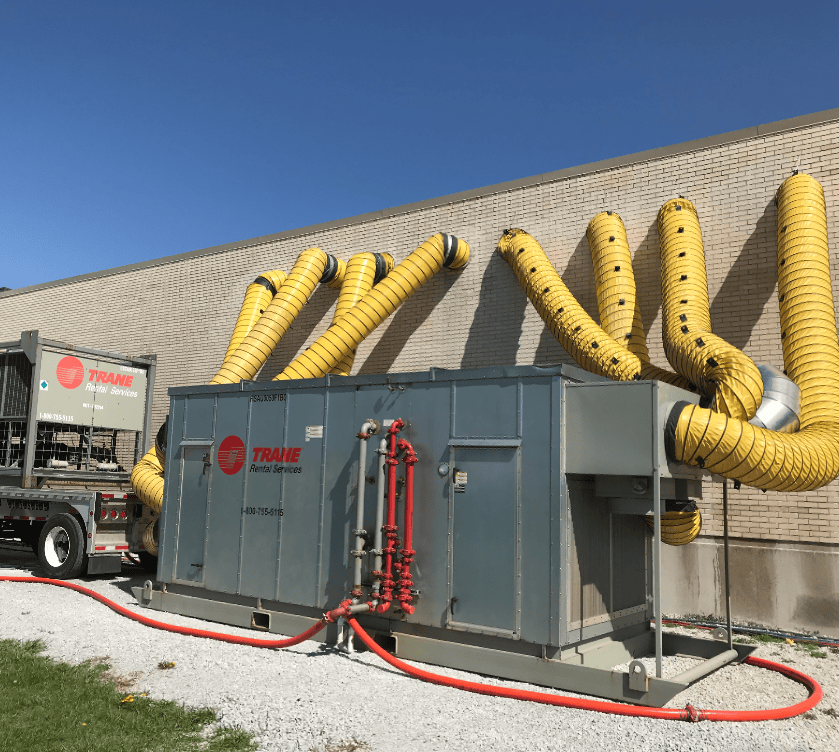

The Solae plant in Remington, Indiana, with a 40,000 square foot main building and a five-story packaging tower, was difficult to cool. It was a struggle to maintain high product quality levels during spring and summer when temperature and humidity levels exceeded ideal production conditions. During such times, the plant was forced to discard an estimated 10 to 15 percent of product produced.

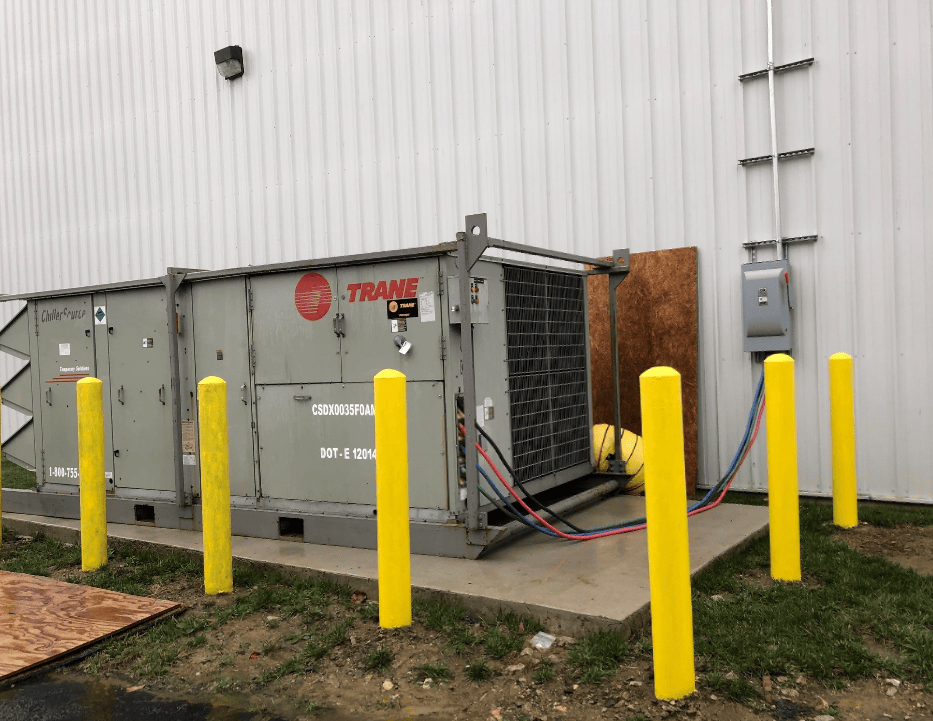

Much needed plant upgrades would have to adhere to strict installation requirements in order to keep the plant explosion proof and free of flammable vapors. In addition, any equipment installed was required to be 4 feet to 8 feet off the ground to stay within zone classifications.

Solution

Based on a thorough understanding of plant business goals, infrastructure needs and safety requirements, the Trane team determined the best solutions to maximize comfort, efficiency and savings.

High-efficiency HVAC systems maintain temperature and humidity levels

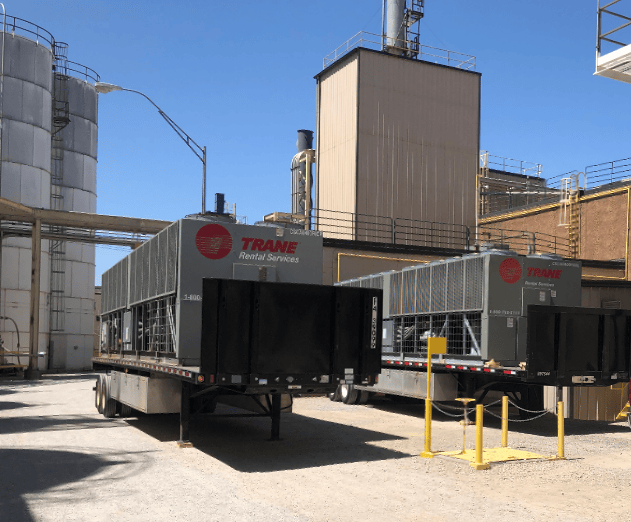

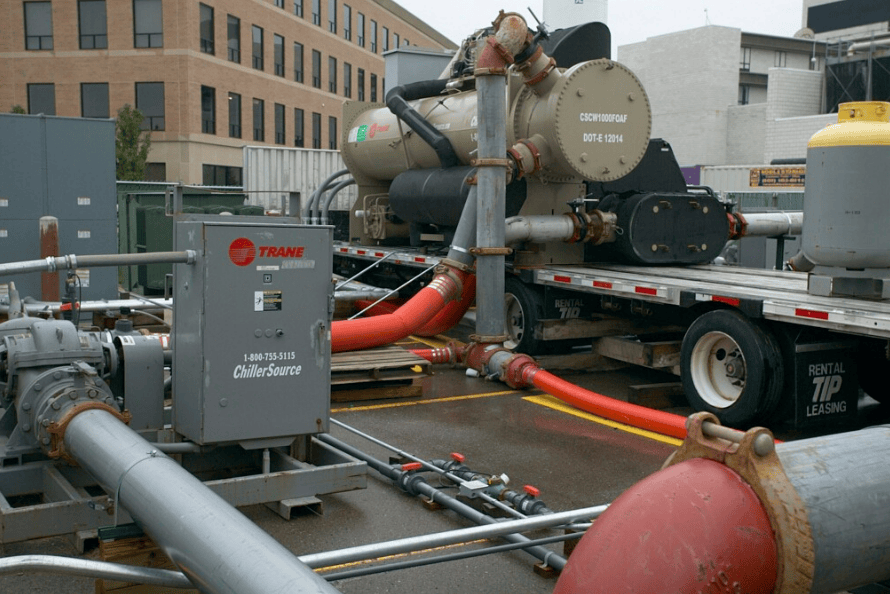

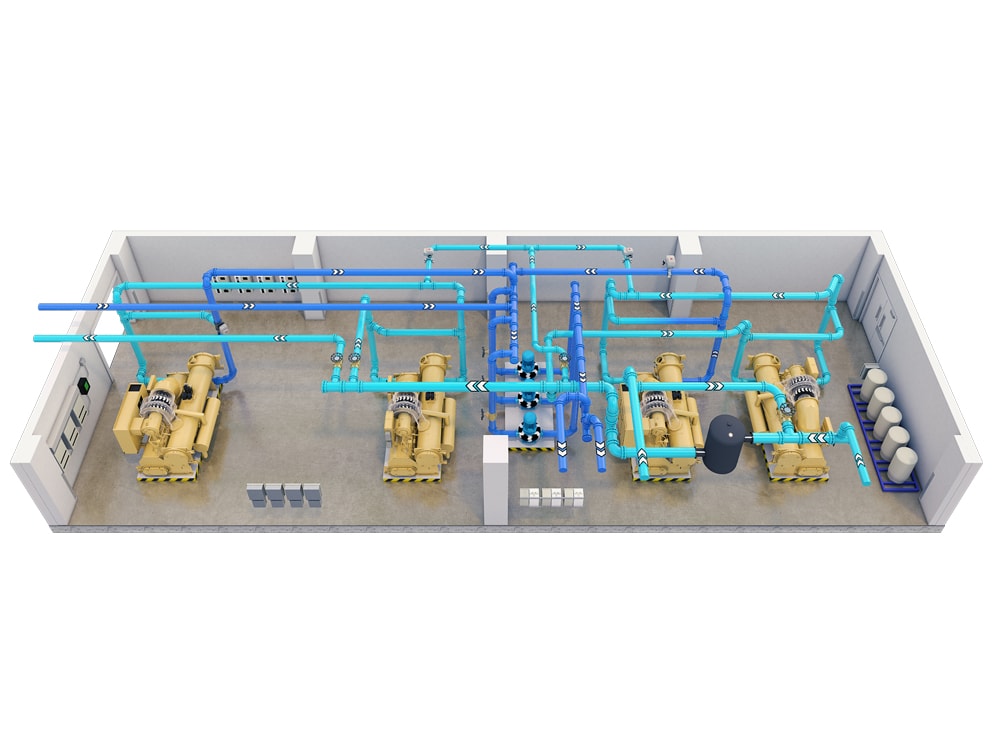

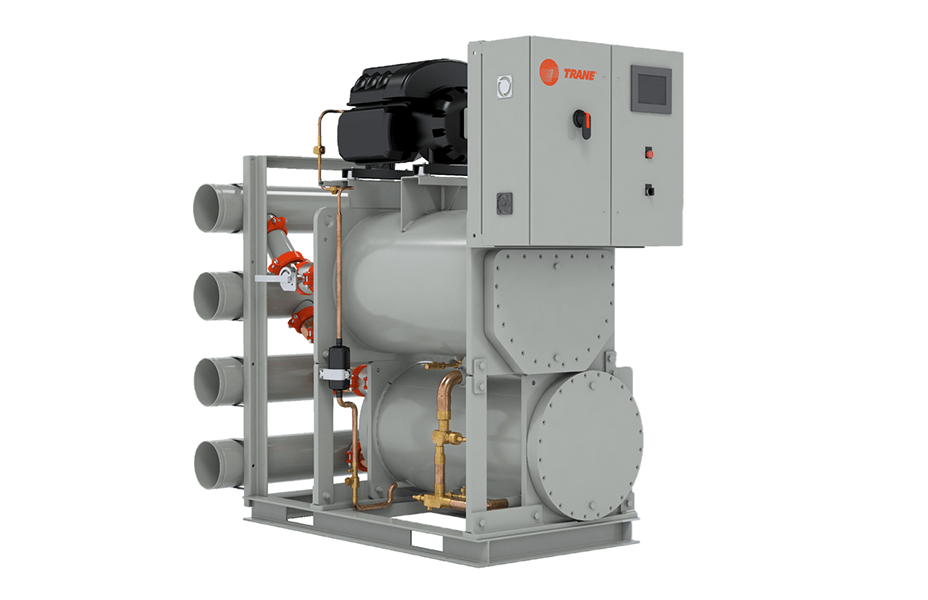

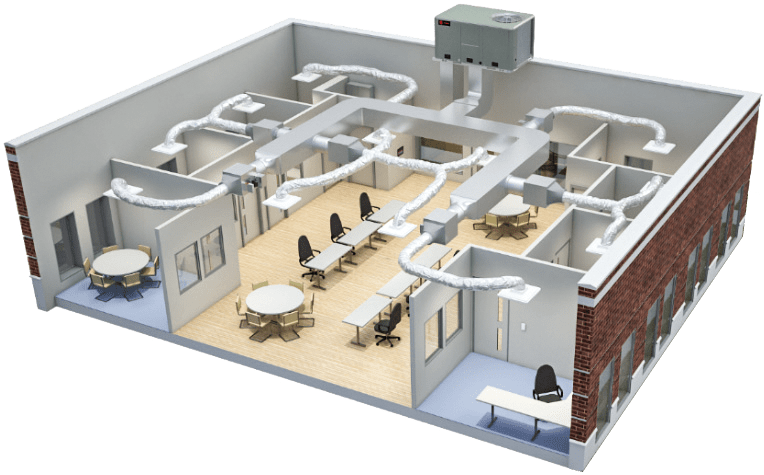

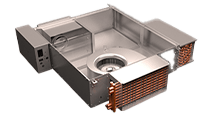

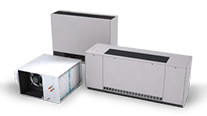

A Trane T-Series Climate Changer™ advanced air handler maintains humidity levels at 30 percent and temperatures within a margin of 2ºC to 4ºC. It also provides sufficient cooling for the previously under-served packaging tower. A second, more reliable chilled water system was added. The system incorporates outside air for higher energy efficiency during colder months.

System controls help assure optimal performance

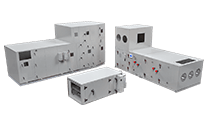

Trane Tracer™ programmable controllers were integrated into the plant system to keep the air handler, chillers and pumps running at optimum levels. The expanded plant system includes additional monitors and sensors, and offers the flexibility of remote access from any computer.

Service agreement extends equipment life

A Trane Scheduled Service Agreement extends the useful life of the systems, reducing costly repairs and improving performance. It assures that all periodic maintenance is being performed, by factory authorized technicians, as scheduled.

Results

The Solae project is expected to provide over $350,000 per year in energy and operational savings with a payback of less than two years. Annual improvements include:

• Product loss down by 2.5 percent

• Equipment downtime reduced

• Energy use cut by nearly 25,500 MMBtu

• CO2 emissions down by over 26 million lb

• Solvent emissions reduced nearly 16,500 gal

• Potable water use cut by 2.5 million gal

• Wastewater down 2.1 million gal

"Trane walked our plant to see the challenges we faced firsthand," said Chris Steinbrenner, assistant plant manager, Solae. "We needed to meet some very specific humidity and temperature requirements to ensure the quality of our product. Trane responded quickly with an effective solution."

"The plant no longer needs to alter production based on weather conditions," added Eric Barber, senior production engineer, Solae. "Previously, this was a common occurrence during high humidity months."

About Solae LLC

The Solae Remington plant includes a five-story packaging tower.