Project Summary

• Polyester Oriented Yarn (POY) and Polyester Staple Fibre (PSF) Manufacturing Plant

• Approximate cost: USD 175 Million

• Construction start date: November 2004

• Construction completion date: March 2007

• Erection and commissioning: September 2006

Challenge

Due to a rapid increase in their business, Indorama had embarked on a significant expansion program. A new process-cooling plant was needed due to insufficient cooling capacity to accommodate new production lines. Indorama established challenging supplier requirements relative to initial first cost, operating costs, reliability, ease of maintenance and available space. Furthermore, Indorama wanted to take an environmentally responsible position.

Solution

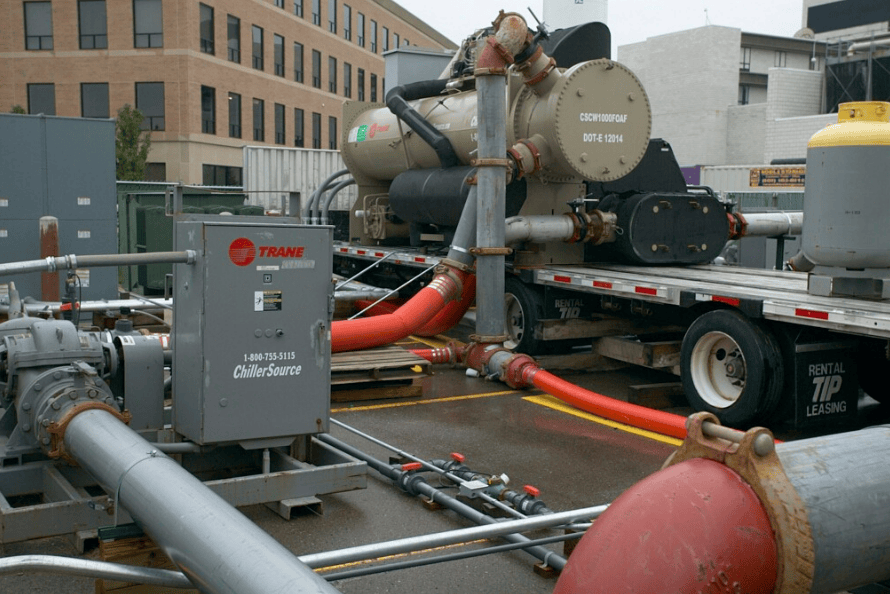

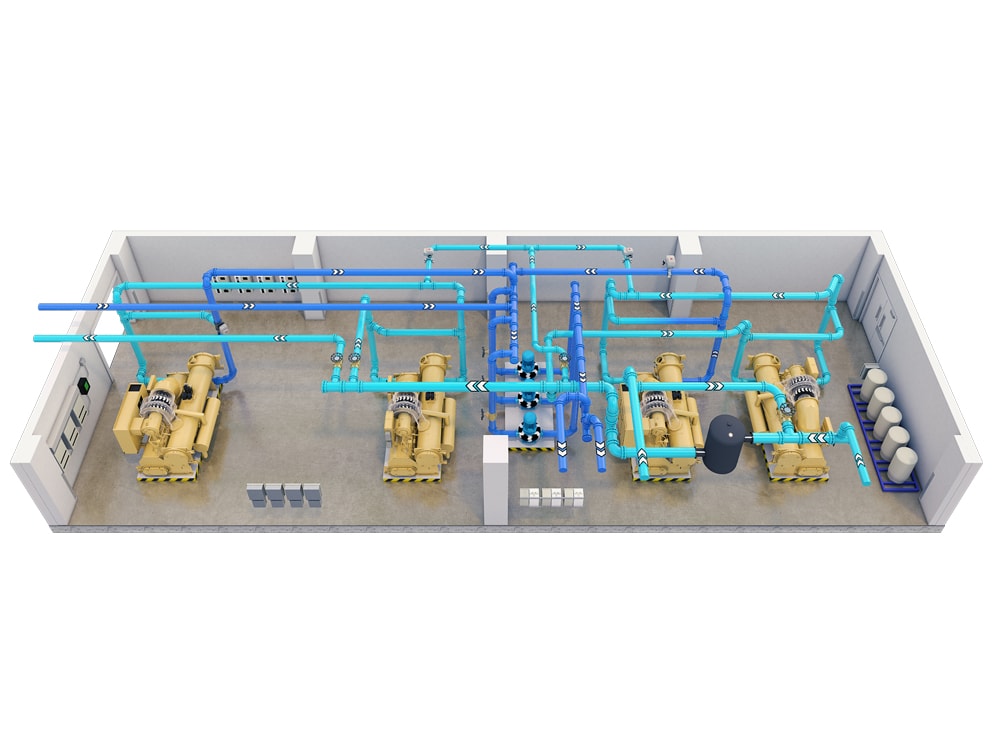

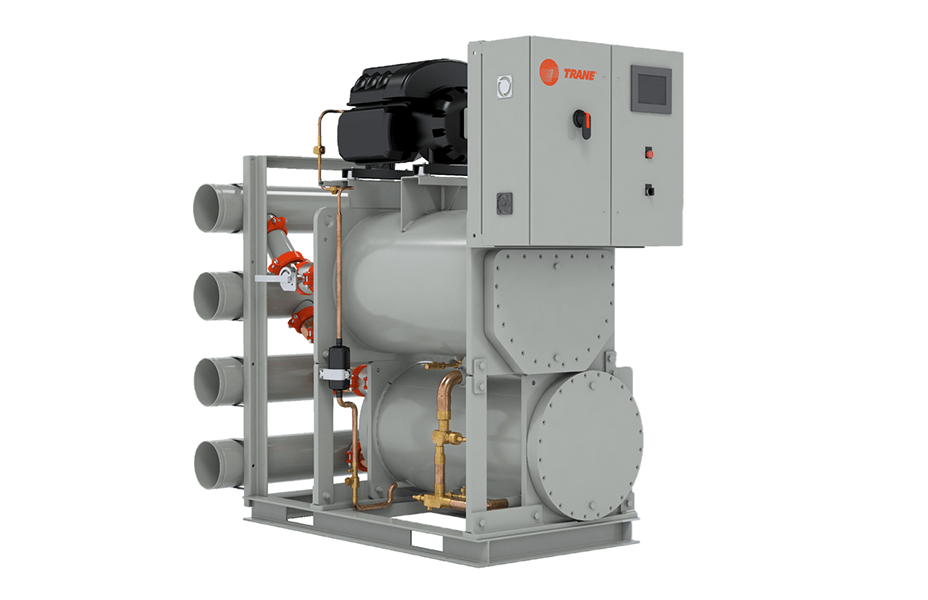

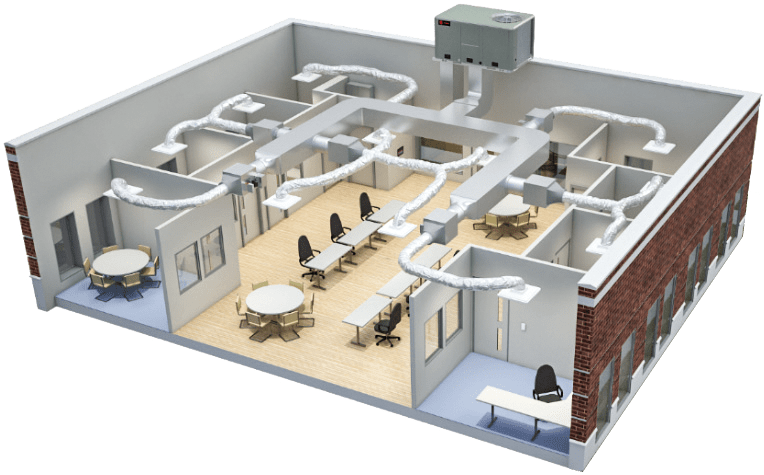

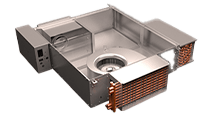

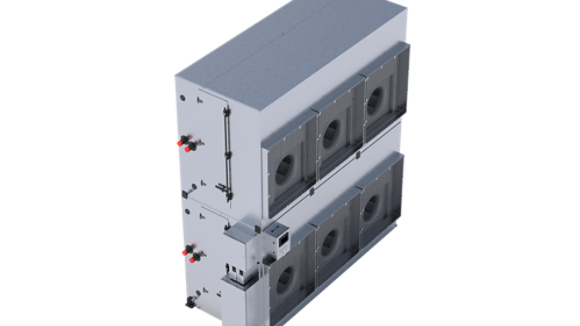

The Trane team considered a range of possibilities before proposing a central processcooling plant equipped with four EarthWise CenTraVac™, water-cooled chillers. These chillers not only provided the required capacity and operating efficiency, but also provided standby capacity for the existing chillers. To maximize efficiency and chiller plant floor space, Trane proposed installing four 1250-ton chillers instead of five 1000-ton chillers. To address ease-of-operation, Trane proposed equipping the chillers with Automatic Condenser Tube Cleaning systems. These devices eliminate frequent down time to clean the tubes and maintain chiller efficiency.

The use of an 11KV electrical configuration also eliminated the need to install an expensive and space consuming step-down transformer. Even starting current is reduced via soft starter thereby reducing the load on the electrical system. A Trane Tracer Summit™ Chiller Plant Management system was also proposed to monitor and control chiller plant operation for maximum efficiency.

Results

Indorama selected Trane, convinced that Trane provided the best overall systems for their business. Indorama also appreciated the fact that the Trane chillers use R-123 refrigerant to deliver excellent operating efficiency while maintaining a responsible, balanced environmental position.

From Integrated Comfort™ Systems to Systems management and Climate Controls, Trane ensures that your building environment is right so you can run your business better.

About Indo Rama Synthetics (I) Ltd.

Indorama Synthetics (I) Ltd. is one of the largest textile companies in India, producing premium quality polyester-based raw materials for the global textile and packaging industry. Indorama products are exported to Europe and North America.