Project Highlights

Location: Pascagoula, Mississippi

Industry: Healthcare

Products Used: Chillers, Controls,

Services Used: Energy Analysis & Monitoring, Energy Efficiency Contracting, Rental Services, Upgrading,

Climate: Humid & Hot

Topic: Efficiency, Cost-Saving, Optimal Comfort, Air Quality,

Challenge

The thirty-year-old original chillers at the Singing River Hospital in Pascagoula were failing. Besides being inefficient, the chillers did not provide the capacity or redundancy the hospital desired. In addition, with the old chiller plant located in the basement, the chillers were hard to access, and in a poor geographical location, when service or maintenance was required. The hospital sought a solution that would increase capacity; provide reliability to ensure the comfort of patients and employees; increase cost efficiencies; and offer redundancy to maintain continuous hospital operation in the event of an equipment issue.

Solution

Singing River Hospital contacted their consulting engineer, Sanders Engineering, regarding the upgrade project. To address the hospital’s challenges, the consultant teamed up with Trane, which was the hospital’s daily service support, and Air Masters, a mechanical contractor familiar with Trane equipment and solutions.

Improving redundancy and efficiency

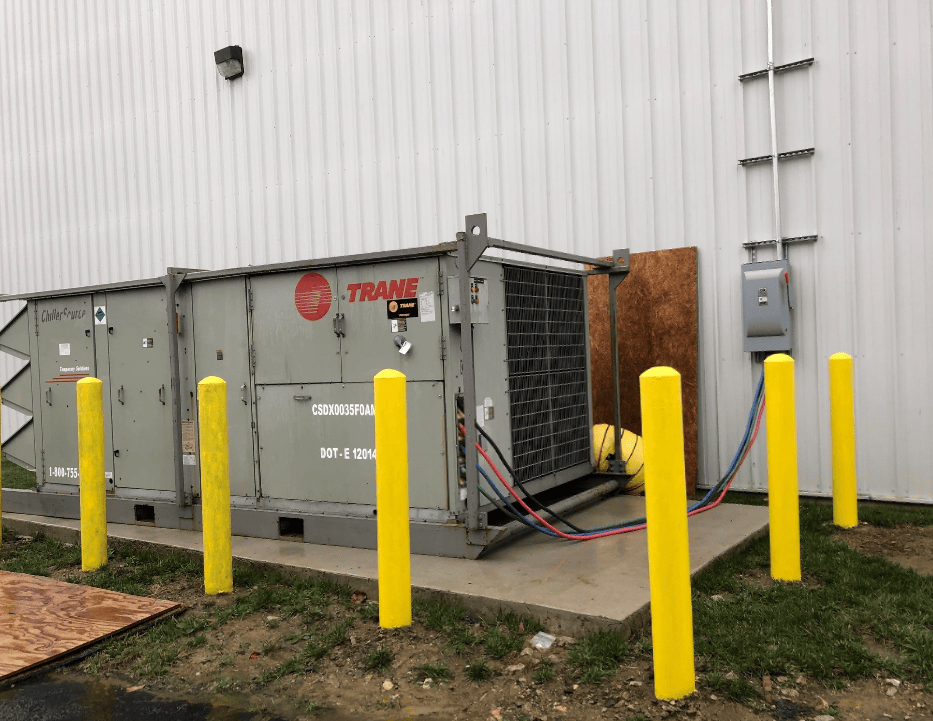

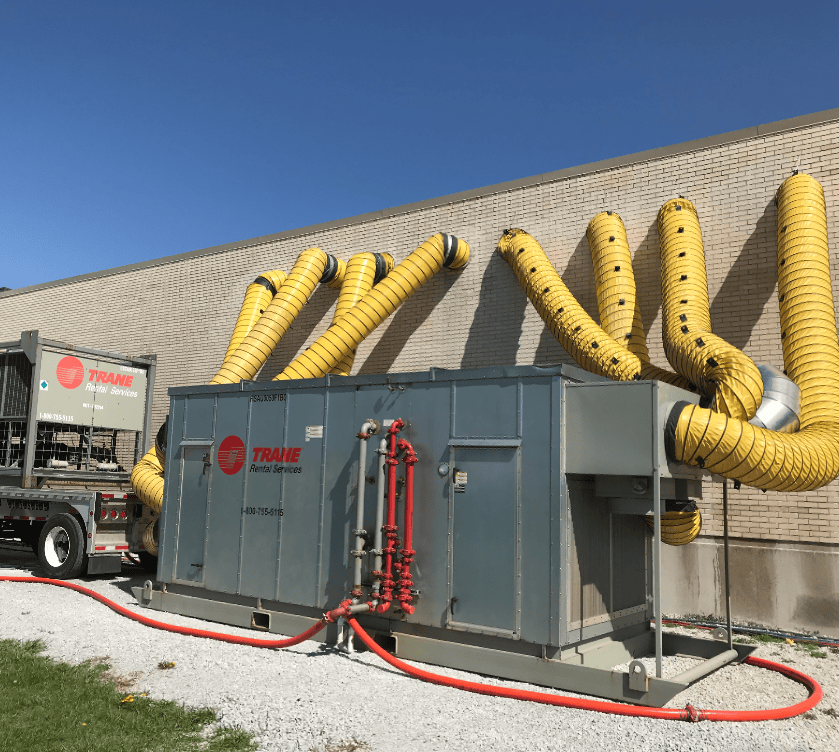

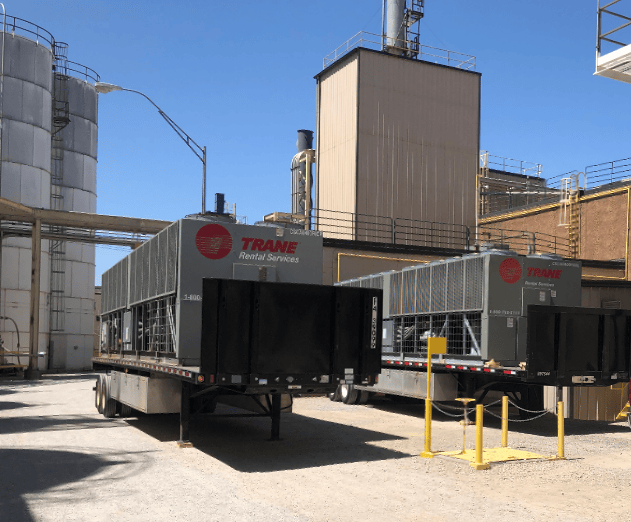

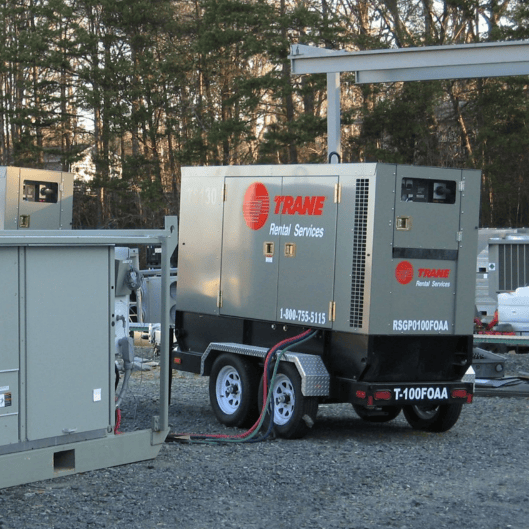

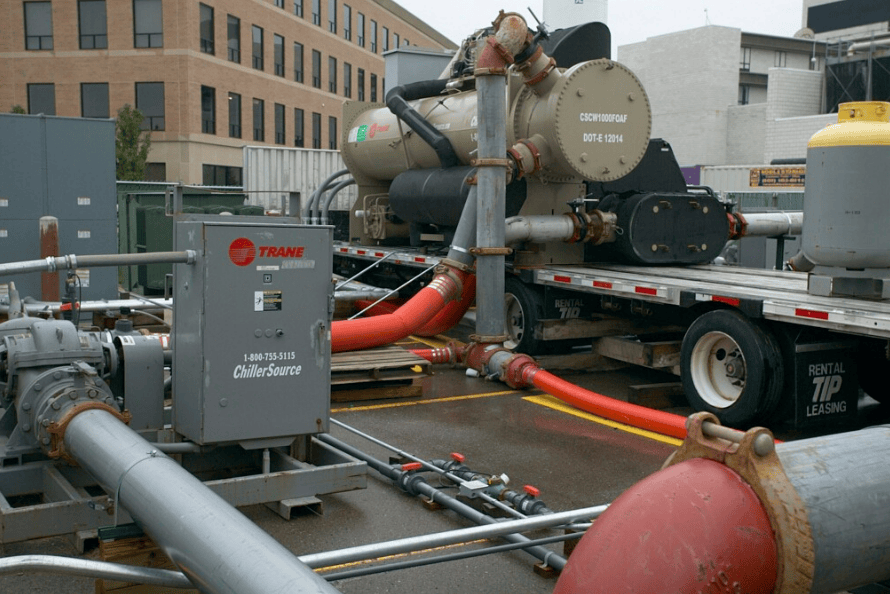

The team moved forward to design a new 2,100k sq ft central energy plant to address the needs of the entire hospital. A 500-ton air-cooled Trane rental chiller was installed to provide temporary cooling to enable the hospital to continue its service to the community during construction.

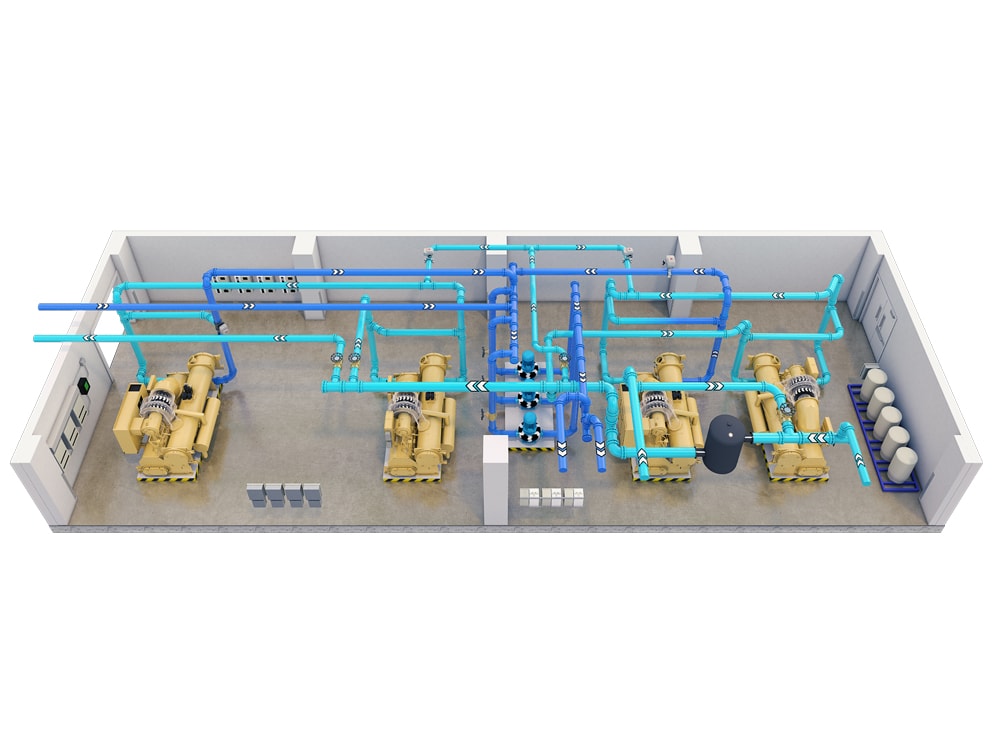

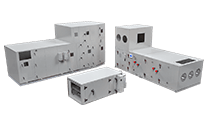

For the new plant, the team selected a site outside of the hospital to ensure easy access for service and maintenance. The central energy plant design included all new equipment and a new cooling tower with controls to provide reliability, reduce downtime and lower maintenance costs; extra capacity to meet the hospital’s growing needs; and redundancy to ensure there would be no interruptions to the hospital’s critical operations. To optimize efficiency, the facility was designed as a variable flow plant, and threeway valves on the hospital’s existing secondary loop air handlers were retrofitted to two-way pressure independent control valves to reduce pump energy usage in the plant.

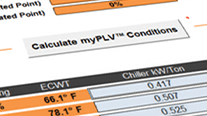

Estimating future equipment performance

The Trane myPLV® calculator, a manufacturer-agnostic tool, was utilized to evaluate chiller options to help make the chiller purchasing decision. With myPLV, users enter their location, building type, building peak load, number and size of the chillers in the plant, and chiller condenser control strategy. The myPLV calculator uses industry-standard building model data, in combination with the user-specific information, to predict applied chiller operating conditions for the specific building and application, and provide an accurate estimate of the chiller’s future performance. Looking at pumping costs with different pressure drops across the evaporator and condenser side, Trane used the myPLV tool to quickly and accurately estimate the energy usage of five different chiller options. The team selected the chiller package with the highest efficiency over the lowest cost option.

Increasing reliability and comfort

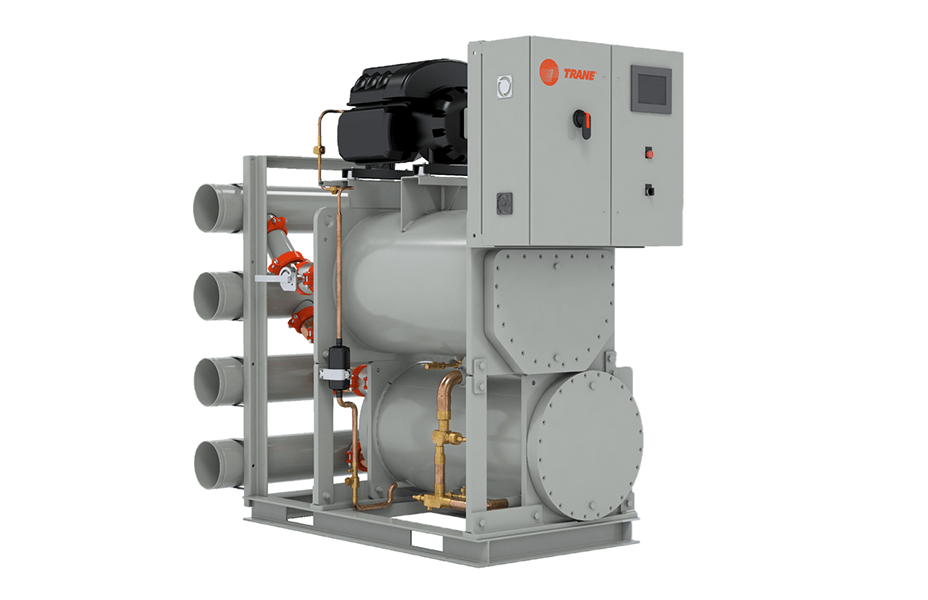

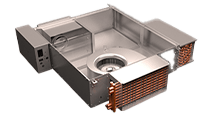

Three identical 650-ton Trane® CenTraVac® chillers were selected to handle the needs of the hospital and provide redundancy to keep hospital operations running smoothly. Factory testing was conducted at Trane’s La Crosse, Wisconsin, plant to ensure the custom-built chillers performed within established tolerances to sustain precise temperatures crucial for critical processes, and proven efficiencies to reduce energy consumption. The CenTraVac chillers offer a simple, robust design, with semi-hermetic motor efficiency and the use of low-pressure refrigerant that provides reliable operation to keep patients’ comfortable; and clean, cool operation for maximum performance. With the CenTraVac’s few moving parts, and the use of marine hinged water boxes, the chillers are easier for Trane service professionals to maintain, helping to reduce labor time and costs. In addition, the CenTraVac’s vibration-free operation ensures a quiet, comfortable environment for patients and hospital staff.

Optimizing operations

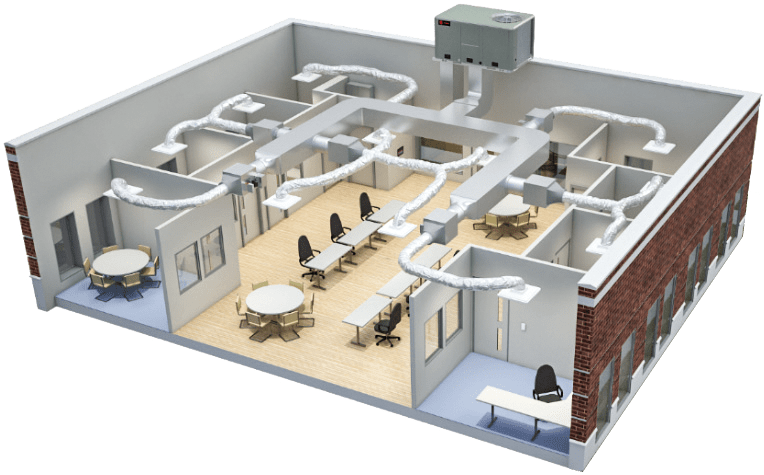

The hospital uses a Trane® Tracer® SC building automation system (BAS) with Tracer® Synchrony™ user interface to control comfort of its facility and energy efficiency of its operations. Accessible from most PCs, tablets, and smart phones, the web-based Tracer SC eliminates the need for a dedicated computer and monitor, allowing facility managers to access HVAC systems on-site or remotely to handle daily operations, adjust temperatures, optimize sequencing routines, establish setpoints, troubleshoot issues and address alarms.

“With the Tracer SC we control cooling, humidity and room pressurization,” said Randall Cobb, director of facility services, Singing River Health System. “We can monitor all aspects of our HVAC system on a 24-hour basis. We can look at our floor plan to make sure we have the desired temperature in our patient rooms at all times. We can see if we are providing enough chilled water to our air handling units, which service surgery rooms and our labs. And in the event of a system failure, we can access the systems remotely to troubleshoot issues and even monitor our emergency generators to ensure they come on in seven seconds as planned.”

Results

A team effort by Singing River Health System, Trane, Sanders Engineering, and Air Masters successfully implemented a new central energy plant and controls system at Singing River Hospital in Pascagoula. The upgrades are enabling the hospital to provide consistent temperatures and humidity levels, improved air quality, and a quiet environment to enable a better level of care for patients and more comfortable working conditions for hospital staff. With the reliable, high-performance central energy plant, the hospital has been able to lower service costs and improve efficiency.

“The biggest benefit of the project is that we have been able to reduce energy costs by about 20 percent,” said Cobb. “We continually work to lower our energy use and carbon footprint to make Singing River Health System a greener company. The money we save on energy will be reinvested in the hospital to purchase medical equipment so we can maintain our top level clinical quality rating.”

Project Highlights

Challenge

- Failing, inefficient chillers

- Increase capacity and redundancy

Solution

- Rental chiller

- New central energy plant

- myPLV calculator

- Trane® CenTraVac® chillers

- Trane® Tracer® SC BAS with Tracer® Synchrony™

Results

- Consistent temperatures and humidity levels

- Improved air quality

- Quiet environment

- Lowered service costs

- Reduced energy costs by 20 percent

- Savings to be reinvested in medical equipment

About Singing River Health System

Singing River Health System is a community owned, not-for-profit health system comprised of two hospitals, plus community medical clinics throughout the area. One of the largest employers on the Mississippi Gulf Coast, the health system employs more than 2,500 associates, including 300 physicians and healthcare professionals. The system provides critical health services, numerous outreach and educational programs, and charitable services to make the surrounding community a better place to live and work. The hospital offers 24-hour emergency services, caring for more than 100,000 patients each year. Its wide scope of offerings includes heart, vascular, rehabilitation, and behavioral health services, cancer care, and state-of-the-art neuroscience centers.