Project Highlights

Location: Brookhaven, Mississippi

Industry: Healthcare

Products Used: Chillers,

Services Used: Upgrading,

Climate: Humid & Hot

Challenge

To minimize the risk of infection, The Centers for Medicare & Medicaid Services (CMS) emphasizes the importance of maintaining operating room (OR) relative humidity at 60 percent or less. In keeping with its commitment to continually improve patient care, King’s Daughters Medical Center (KDMC) began to continually monitor all of its operating rooms, finding that the existing mechanical systems could maintain the OR relative humidity at 60 percent or lower as long as the OR space temperature was maintained at 68°F or higher. However, most surgeons expect the OR space temperature to be between 62°F and 66°F to be comfortable and focused while performing surgery. “Performing surgery is very intense, so we want our surgeons to be comfortable,” explained Alvin Hoover, CEO, KDMC. “The hospital made a commitment to achieve the cool dry conditions in our ORs that will keep our surgical teams comfortable, while at the same time comply with the CMS relative humidity standard.”

Solution

Based upon Scott C. Woods & Associates (SCWA) long track record of delivering mechanical engineering solutions for KDMC, the hospital met with the firm to discuss their relative humidity/temperature challenges, as well as their objectives of increasing chilled water plant reliability and achieving 100 percent redundancy in their hospital chilled water cooling plant in the most cost effective and energy efficient manner possible.

Evaluating the options

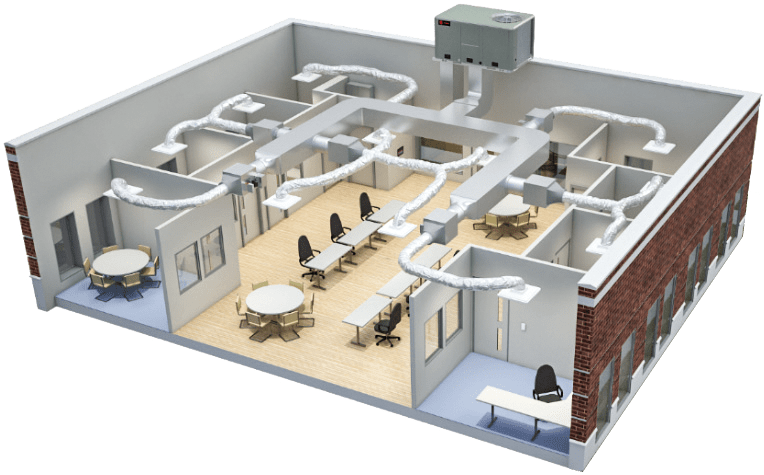

SCWA considered retrofitting the airside systems, but the option was deemed undesirable due to shut-down time required for construction and high costs. SCWA invited Trane to partner with them in evaluating options for a chilled water plant solution. The team looked into converting the plant to a low temperature glycol system but rejected the option due to high cost and high maintenance requirements. The team evaluated a third option of replacing the old existing chiller with a larger Trane centrifugal chiller designed to deliver 34.5°F chilled water to the entire hospital without the use of glycol. “Replacing the old small chiller with a new larger, low temperature chiller without the use of glycol would give us flexibility and reliability, while minimizing cost,” said Scott Woods, PE, SCWA.

Increasing capacity, reliability, and redundancy

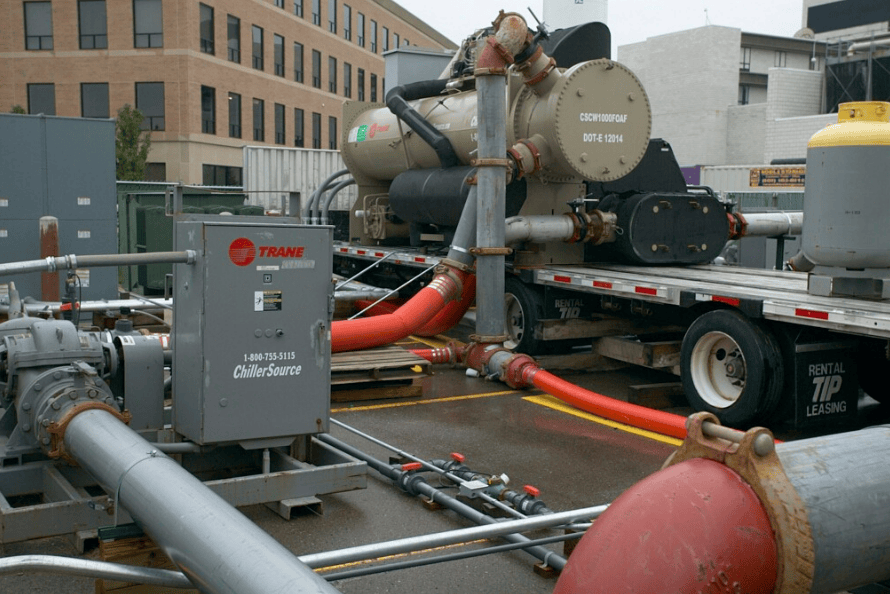

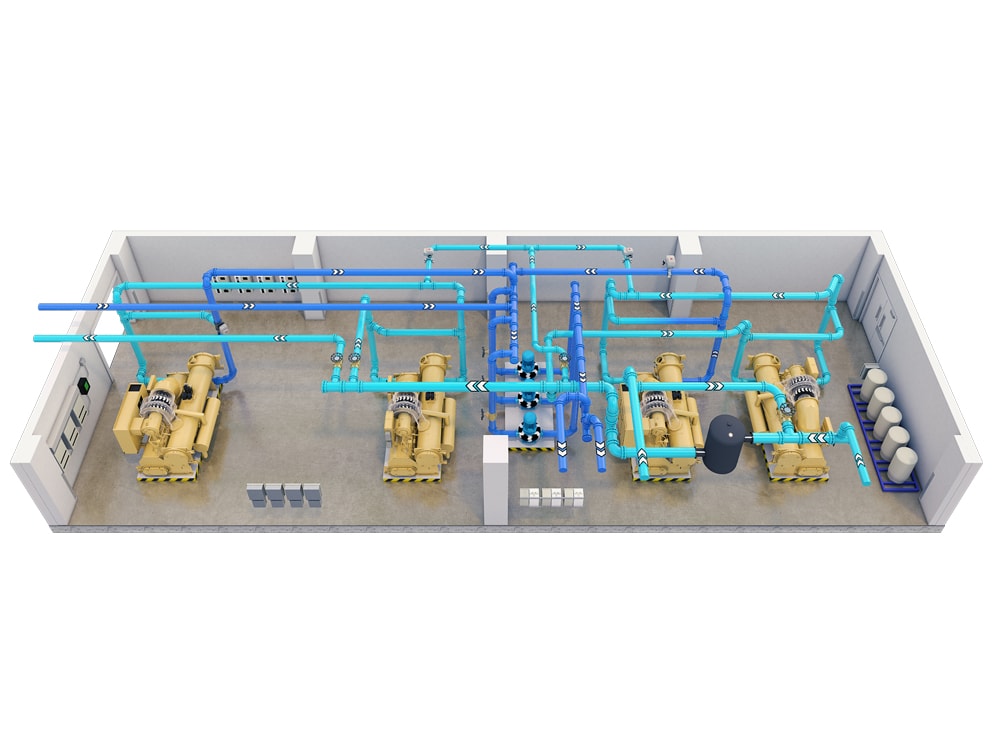

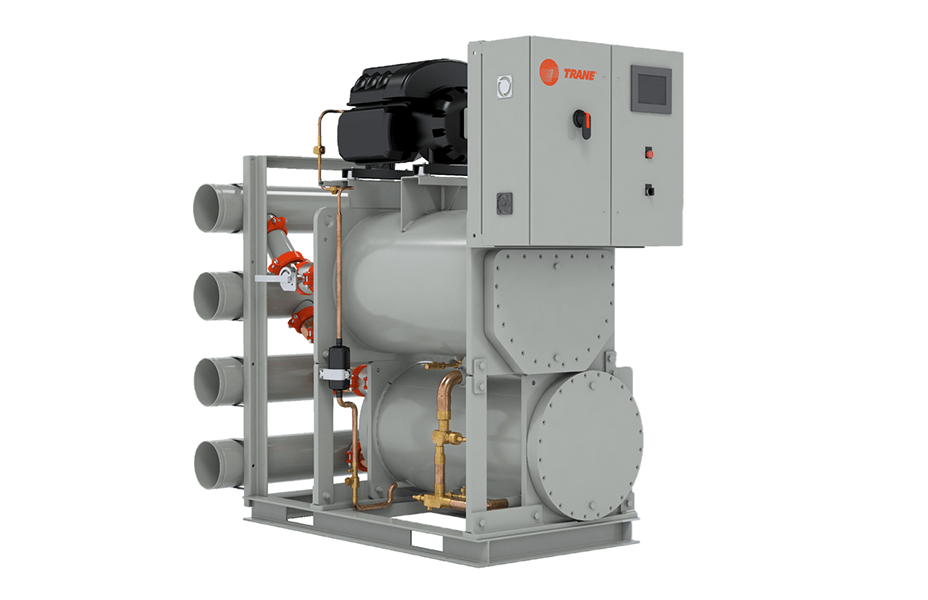

The mechanical engineer and Trane proposed replacing the hospital’s smaller chiller, which had reached the end of its useful life, with a new larger, low flow, low temperature, 475-ton Trane® CenTraVac® water-cooled centrifugal chiller. The upgraded chilled water plant would now consist of one new 34.5°F, 475-ton Trane chiller and one existing 42°F, 475-ton Trane chiller, for increased reliability and 100 percent chiller plant redundancy. After careful evaluation, it was determined that the proposed solution would achieve the desired cool, dry operating room conditions for the lowest capital investment at the lowest operating cost. The solution also delivered on the goals of maximizing the hospital’s chiller plant redundancy and reliability.

Maintaining optimal environment with efficient design

The low flow, low temperature chilled water system was designed to operate under a broad range of conditions to accommodate KDMC’s current and future needs. The CenTraVac delivers the industry’s highest full- and part-load efficiency at a constant 34.5°F leaving chilled water temperature without the use of glycol, maintaining operating room relative humidity between 50 and 60 percent, while giving surgical teams the flexibility to select OR temperatures as low as 62°F to suit their expectations.

Results

The new low flow, low temperature 475-ton Trane CenTraVac centrifugal chiller, installed by McLain Plumbing, is exceeding expectations and enabling KDMC to realize its desired cool, dry operating room environment. The ORs are in compliance with the CMS OR relative humidity requirement. The larger, robust chiller has increased the hospital’s cooling capacity, redundancy, reliability, and flexibility for future hospital expansions. Operating room temperatures are running between 62°F and 66°F at relative humidity between 50 and 60 percent, as verified and logged prior to surgeries by the head surgical nurse, and continually monitored in real time and recorded every five minutes by the hospital’s controls system. Infection rates at the hospital are below regional averages, and surgeon complaints have been all but eliminated. The new 34.5°F chilled water system has operated throughout three high humidity Mississippi summers with no condensation issues. “Before installing the new 34.5°F Trane chiller, we had to keep our operating room space temperature at 68°F or higher to prevent the space relative humidity from exceeding 60 percent. We also used to get complaints from surgeons on a daily basis, sometimes four or five work orders for one operating room in one day,” said Ronnie Killingsworth, Director of Facilities Engineer, KDMC. “Now we will typically go a month or more without having a single OR complaint. Surgeons have the freedom to set their OR temperature between 62°F and 66°F, and we are able to keep the OR between 50 and 60 percent relative humidity.”

“I consider the hospital and our team to be trailblazers,” added Woods. “This is the first system like this in operation in our entire state.”

Challenge

- OR relative humidity requirement

- Surgeon low temperature demands

- Need to increase chiller plant capacity, reliability and redudancy

Solution

- Low flow, low temperature chilled water system with 475-ton Trane® CenTraVac® water-cooled centrifugal chiller

Results

- Cool, dry operating room

- Achieved operating room relative humidity requirement

- Cool, comfortable surgeons

- Increased cooling plant capacity, redundancy, reliability

- Flexibility for future expansion

- Reduced comfort complaints

- Confirmed regulatory compliance