Project Highlights

Location: Washington

Industry: Commercial Real Estate

Products Used: Chillers,

Services Used: Energy Analysis & Monitoring,

Climate: Dry & Cold

Topic: Sustainability, Innovation, Efficiency, Cost-Saving,

Challenge

Believing that the conservation of resources is a corporate and individual responsibility, Morguard embeds the principles of sustainability into its business. The company strives to identify and apply innovative building solutions to its owned and managed properties, in order to reduce its environmental footprint and ensure its contribution to the development of a sustainable society into the future.

The property manager was looking for ways to improve operations at Coquitlam Centre with the facility's big cooling load. “I wanted to make the property more efficient and cost effective for the Coquitlam Centre owners,” said Ken Petherick, operations manager, Morguard. “We previously implemented lighting upgrades and added direct digital controls, but we were looking for a bigger savings.”

Solution

Morguard and Trane had a long-standing relationship that spanned many years and included a variety of equipment, controls, service and maintenance projects. Based on their successful past experience, during a routine visit, the Morguard operations manager took the opportunity to discuss efficiency improvement methods with their Trane representatives. “It’s something I ask every time I talk to my business associates,“ said Petherick. “How do I optimize operations by reducing cost in a responsible way?“

Designing a creative energy-saving solution

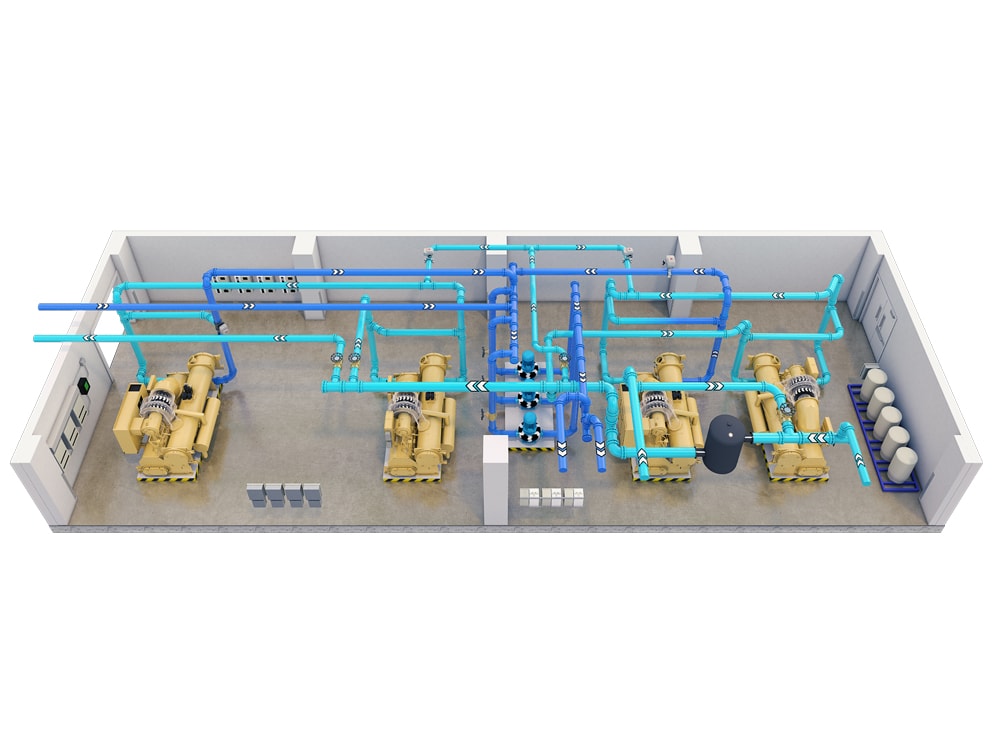

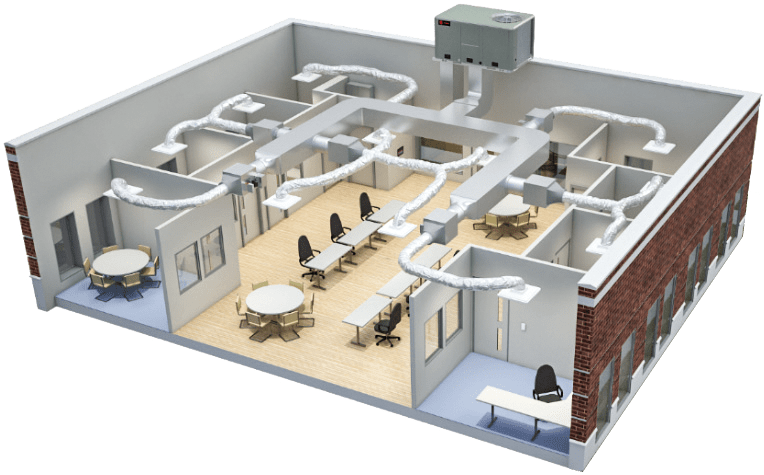

Knowing the configuration of the centre’s mechanical room with chillers and boilers in the same room, Trane suggested heat recovery as an option to reclaim and reuse the current system’s waste heat that was being vented into the atmosphere. The waste heat would be used to heat Coquitlam Centre, providing a substantial energy savings. Interested in the heat reclaim solution, Morguard engaged SES Consulting to evaluate its energy savings potential.

Maximizing use of recovered heat

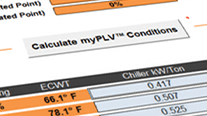

Trane engineers and SES Consulting worked together to verify design details and the feasibility of the heat recovery system. The team developed a sequence of operations to maximize the use of the recovered heat and compiled energy savings projections for the project. The energy study data was provided to FortisBC to enable funding support for the project. Morguard’s operations group included the heat recovery project details and budget in its capital plan, and presented it to the company’s management group for review and approval.

Providing reliability and efficiency

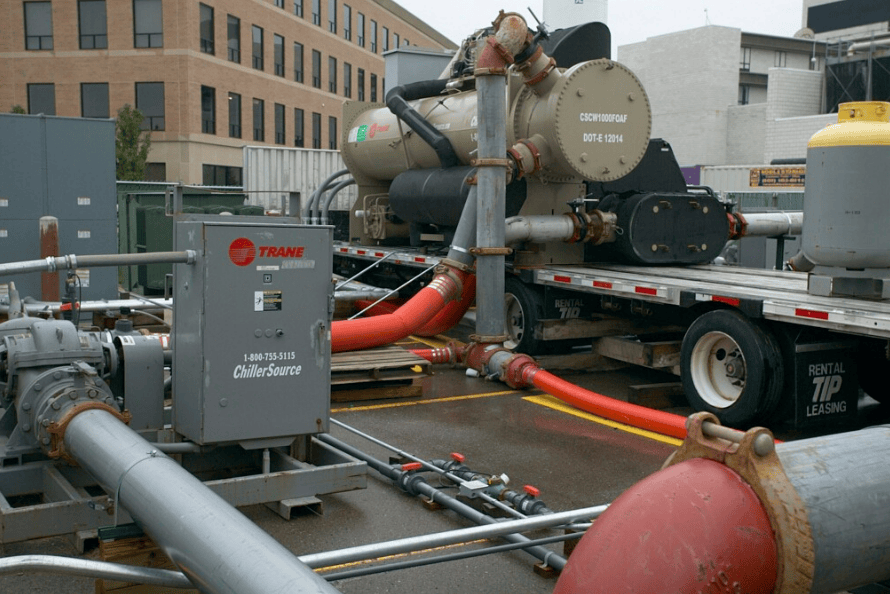

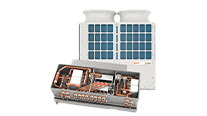

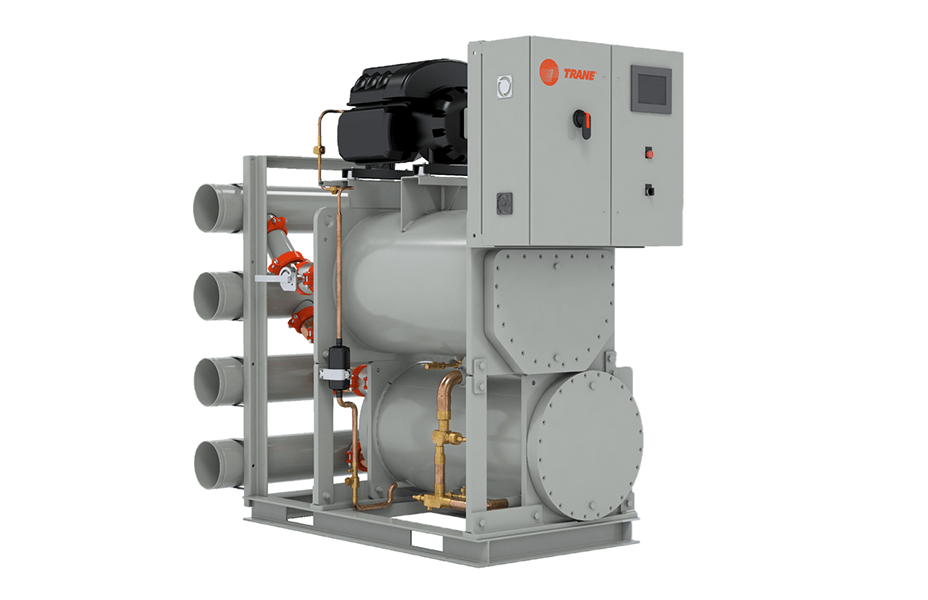

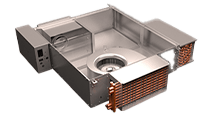

The heat recovery system utilizes a Trane® Series R™ (model RTWD) heat reclaim chiller. With its compact size, the chiller fit easily through the mechanical room doorway, making installation fast and easy. The chiller’s low speed, direct drive Helical Rotary compressor, with only two rotating parts, offers reliability and helps to reduce energy costs. Used in heat recovery mode, the Series R chiller generates leaving condenser water temperatures as high as 140°F (60°C).

Results

Demonstrating its commitment to energy conservation, Morguard, working with Trane, implemented a heat recovery system to reuse waste heat at Coquitlam Centre. The project is generating a substantial energy savings, with early results showing a 55 percent reduction in natural gas consumption, and is on track to meet Morguard’s project criteria with a four and a half year payback. Based on projected energy savings, the upgrade has also earned a substantial incentive from FortisBC to help fund the heat recovery improvements.

“The equipment is certainly doing its job. We do water harvesting on the roof, and collect make-up water. With the more efficient cooling towers not running as much, most of the water we collect is rain water,” said Petherick.

“This heat recovery project has given us a lot of satisfaction. It was a team effort, and it took a lot of effort from many different groups,” Petherick added. “It has been one of the most energy efficient projects I have worked on and the results are going to be amazing!”