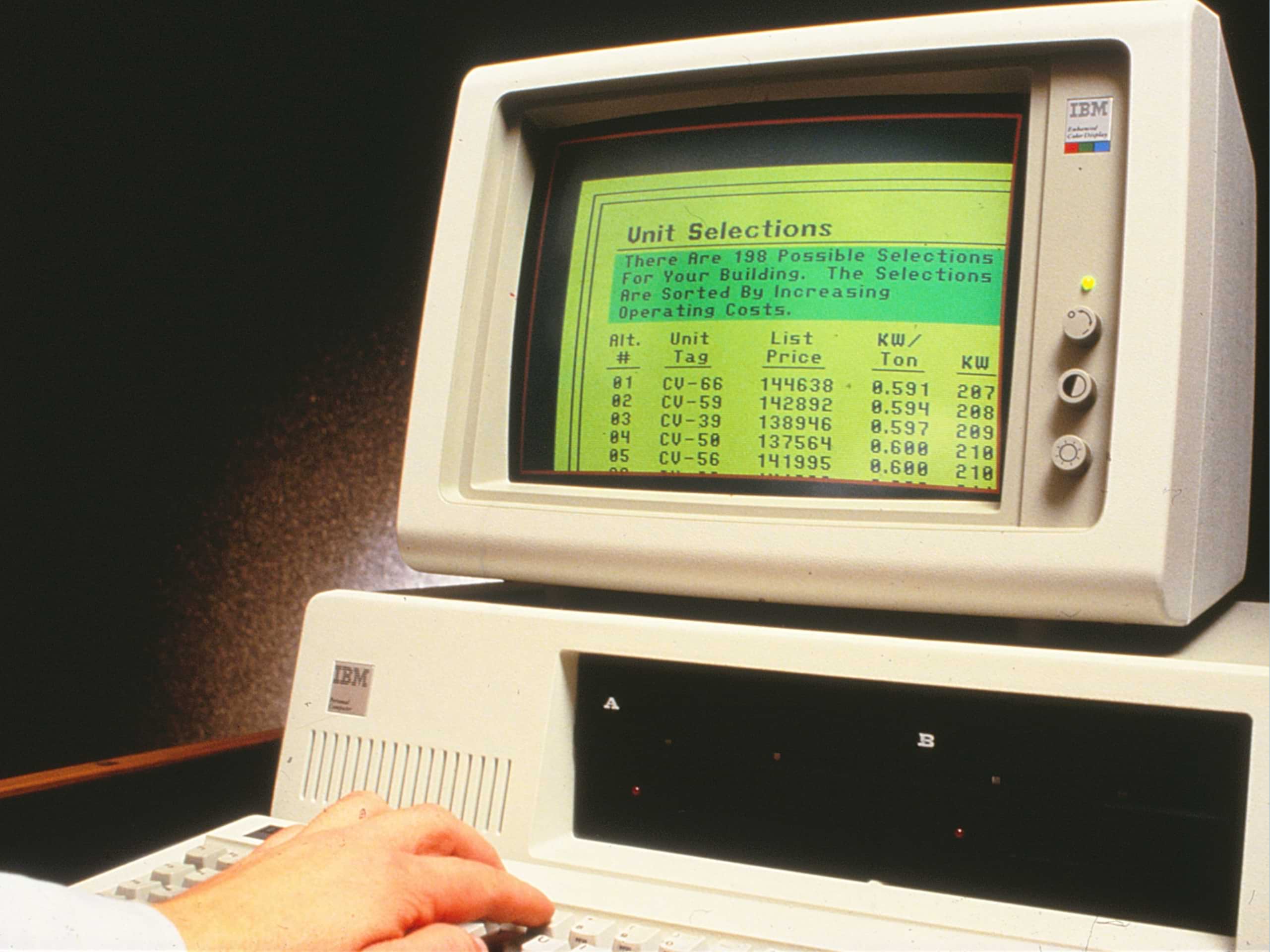

"It was like the Wild West," said Biesterveld. "Anybody could present their results, whether it was good engineering, bad engineering, or in between. Two different firms could come back with completely different answers on coil sizing, for example, and nobody knew who was right."

The industry had a vested interest in developing common standards for design software. Trane, ASHRAE®, the Department of Energy (DOE), and other collaborators helped get everyone on the same page, standardizing design algorithms.

"The DOE recognized they needed to computerize their processes because the government manages more square footage than anyone," said Biesterveld. "There was a lot we could do to make buildings more efficient. We just needed to develop better, more unified processes."

Trane contributed by developing TRACE® design-and-analysis software in 1973. It gave engineers a new tool to make fast and accurate calculations.

The Personal Computer Revolution

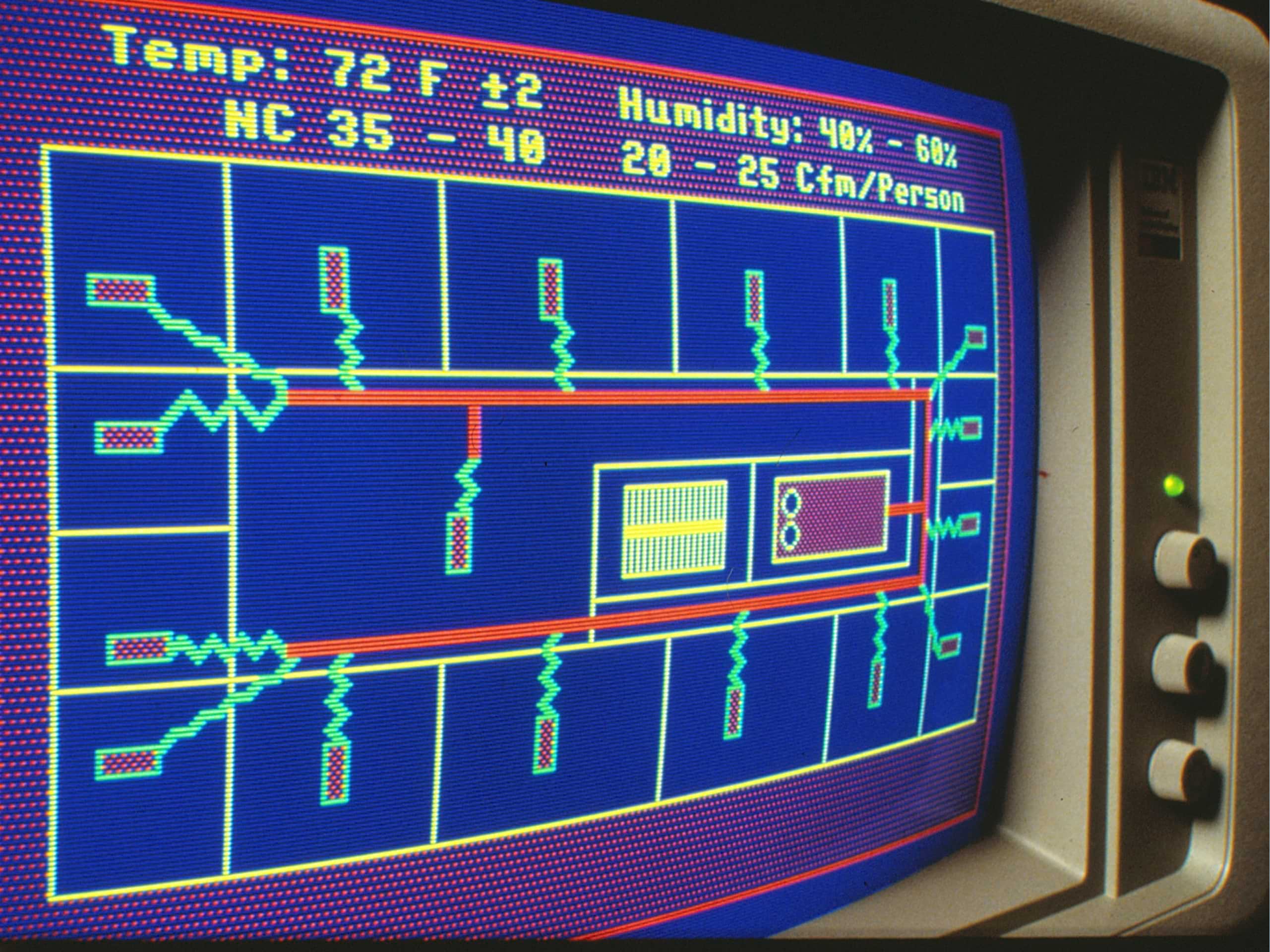

Trane's computational leadership gained the company a lot of respect in the industry and gave engineering firms a trusted resource to help them embrace these new tools. Design software became even more powerful in the 1980s when everyone shifted from mainframes to desktops.

Still, the legacy of paper spreadsheets and punch cards persisted in small but meaningful ways. Reference numbers, which indicated how each piece of equipment would connect to the central system, were still part of the process.

"If you had a big building, the hardest thing was making sure those references were correct," said Biesterveld. "You might have 300 zones, and each one had dozens of references to connect the loads to the system and plant components. Keeping all that straight was tricky and error prone. When TRACE made the shift between key personal computer software platforms, that took the majority of the reference complexity out of the mix, making modeling much easier."

TRACE Provides a Powerful Design Tool

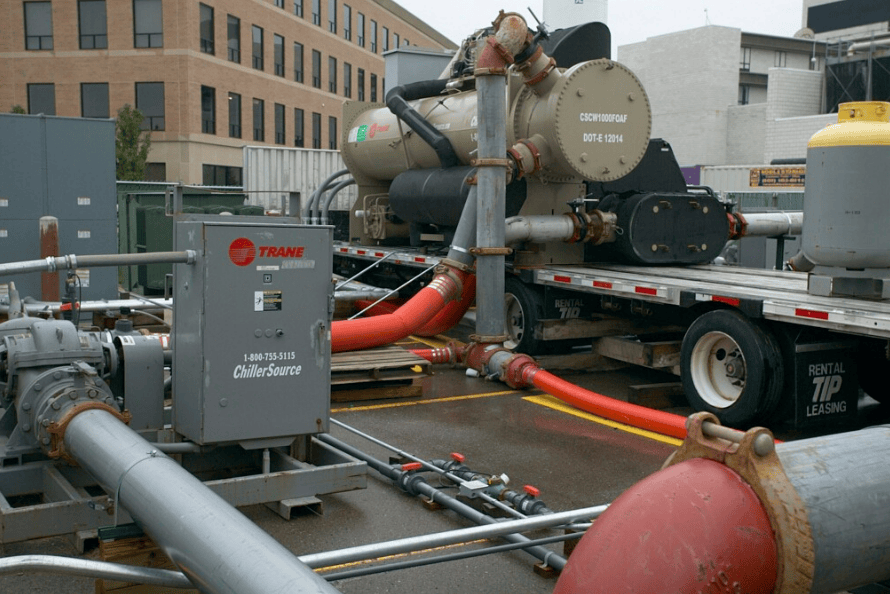

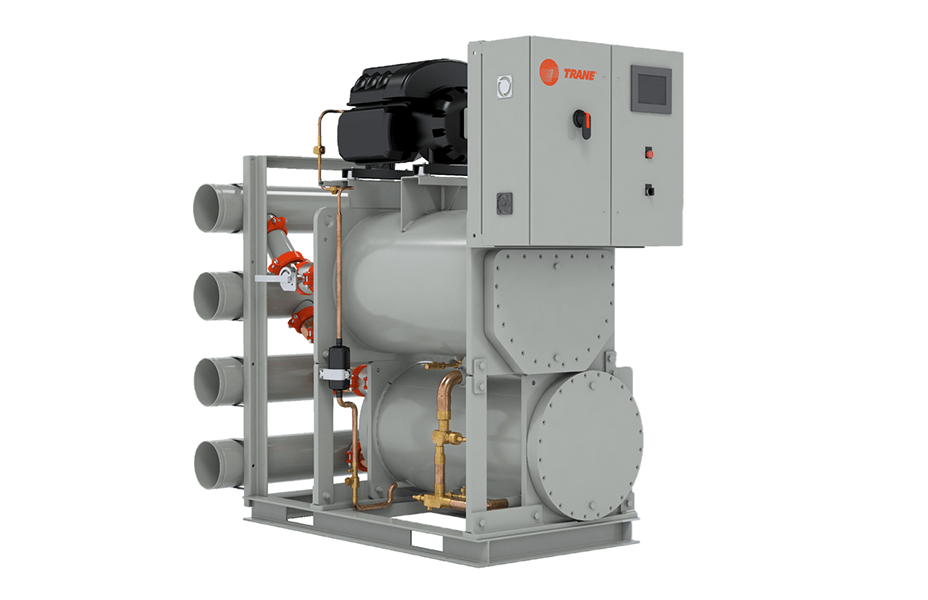

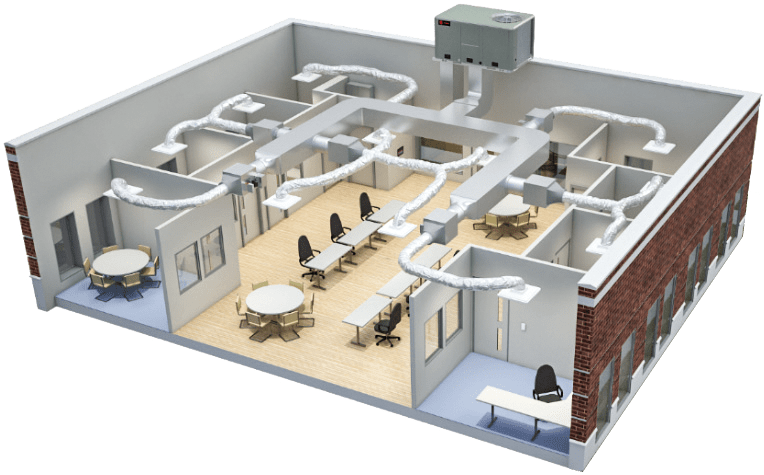

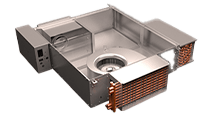

Over the years, TRACE software revolutionized system design and analysis, helping engineers rapidly and accurately size coils, fans, air handlers, and other HVAC system components. Using simulation methods to model potential outcomes, the tool compares equipment choices to help engineers optimize building designs and operations.

Using DOE benchmarking tools, designers can help provide useful high-level estimates and comparisons for a building's energy use over time. The same advantages apply to older buildings needing retrofits, helping calculate which systems to replace and how fast owners can expect to recoup their investments.

"You can change any number of parameters and compare them to one another to see what makes sense from a first cost or lifecycle cost perspective," said Eric Sturm, Applications Engineer and Trane historian. "What if I change components in my building like windows, walls, or insulation? What if I apply shading or certain types of controls? What if I change the HVAC system?"

The Voice of the Customer

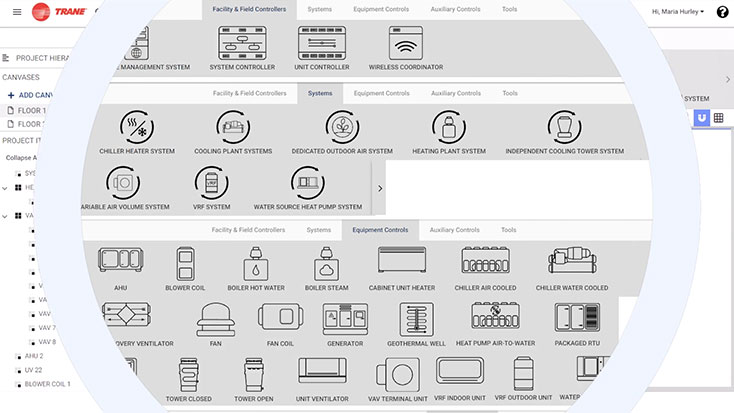

These software tools continue to evolve. As computer hardware has gained speed, Trane's design and analysis software portfolio has gained capabilities, increasing functionality and ease of use. Many of these improvements have been inspired by Trane's customers and engineers.

"Our systems and applications engineering teams always stay connected with the field, providing insights on regulatory and other trends in the industry," said Victor Mirasola, Trane Systems Tools Portfolio leader. "Regulations drive equipment selection and that ultimately drives our work on the modeling side."

Like the industry, the tools development team is focusing heavily on the electrification of heat, comparing traditional boiler systems to electrified alternatives and calculating the potential economic and carbon impact. They are also paying close attention to customer feedback on ease of use.

"Recently, the number one theme we've gotten from our customers is simplifying the workflow," said Mirasola. "We're looking at how we can make some assumptions, giving users the option of fewer buttons. They don't have to make every single judgment call. We can use our engineering expertise to automate logical choices, such as auto-sizing and tasks like that."

Trane continues to work closely with the DOE, sharing non-proprietary technology to support the department's open-source energy management program, EnergyPlus™. The DOE provides much of the academic underpinning, while Trane brings both market and software development insights.

Over the years, Trane has expanded its digital tools to support other HVAC elements, such as acoustics. The Trane Acoustics Program (TAP) helps engineers analyze how equipment impacts interior and exterior sound.

"It always comes down to what customers are looking for and what's important in the market," said Sturm. "Energy, proper sizing, equipment, economics – these have been important forever."

Trane has a wide range of design and analysis software tools, and the development team is investigating ways to combine some of these to make them more user-friendly.

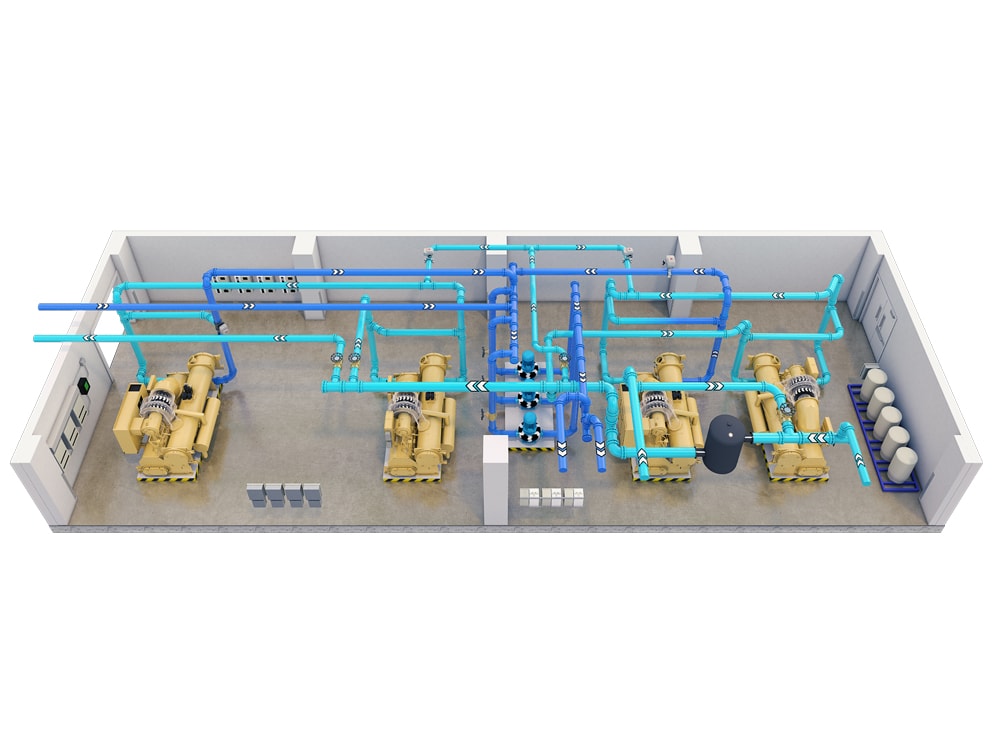

"There are holistic solutions we are exploring – a single program for the entire workflow, for instance, including design and sizing all the way through piping and ducts," said Mirasola. "There's been interest from our field folks for more simplicity. We hear that and are continuously working on it."

Watch Related Videos

-

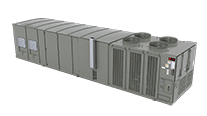

Meet Trane’s CDS Design and Analysis Tools

Meet Trane’s CDS Design and Analysis ToolsDesigning mechanical systems for commercial buildings requires managing small details, big decisions and complex analysis – all while keeping building owners happy. Trane’s suite of CDS Design and Analysis tools are purpose-built to support your design process from initial system selection and concepting, through energy load analysis and detailed design development.

-

Simplify System Control Strategy and Design with Trane® Design Assist™

Simplify System Control Strategy and Design with Trane® Design Assist™Designing a modern, connected building automation system requires balancing a range of factors from increased occupant expectations around comfort control to changing energy efficiency standards and broader sustainability and decarbonization goals. Trane® Design Assist™ is a collaborative design tool built to put proven control strategies and industry best practices at your fingertips.