Project Highlights

Location: Altanta, Georgia

Industry: Community Spaces

Products Used: Chillers, Controls, Building Automation Systems,

Services Used: Energy Analysis & Monitoring, Energy Efficiency Contracting, Start-up Maintenance, Upgrading,

Climate: Humid & Hot

Topic: Decarbonization, Efficiency, Energy Services, Financial Solutions, Products and Solutions, Lighting,

- Reduced energy use by more than 39 percent

- Saved 20 million+ kWh of electricity and $2.5 million+/yr

- Reduced natural gas by more than 240,000 therms a year

- Reduced water usage by 17 million gallons per year

- Recycled 289 tons of construction waste

- Received $422,264 in utility company rebates

- Provided $876,141 in annual operational cost savings

- Achieved LEED Gold certification, maintaining its designation as the world’s largest LEED certified convention center

Challenge

With aging HVAC equipment and a variety of lighting fixtures requiring replacement, Georgia World Congress Center Authority (GWCCA) was in need of upgrades to improve reliability, safety and aesthetics. The complex also wished to increase efficiency by consolidating its four mechanical plants into a central plant that would work seamlessly throughout the facility, and sought to maintain its designation as the world's largest LEED® certified convention center. “We wanted to improve our competitiveness in the marketplace,” said Jeff Oden, director of project and program management, GWCCA. “That included enhancing the customer experience, reducing long-term risk, and modernizing our facility.”

Georgia World Congress Center Authority

Solution

GWCCA selected Trane as their upgrade partner through Georgia's Energy Savings Performance Contracting program, which enables a construction project to use energy and operational savings to pay for efficiency improvements. Trane and GWCCA conducted an in-depth audit, reviewing energy bills to determine areas of high energy use, and prioritizing energy conservation measures based on savings potential.

“Trane understood our complex systems and the challenges of our unique 365 day a year facility. Sustainability was also a key component of their proposal,” said Tim Trefzer, sustainability and corporate social responsibility manager, GWCCA. "They were the best fit for the project.”

Assembling the design-build team

Trane assembled a design-build team consisting of GWCCA and best-suited external companies. The thirty-person group poured through hundreds of drawings and thousands of utility data points, and brainstormed ideas to accomplish objectives.

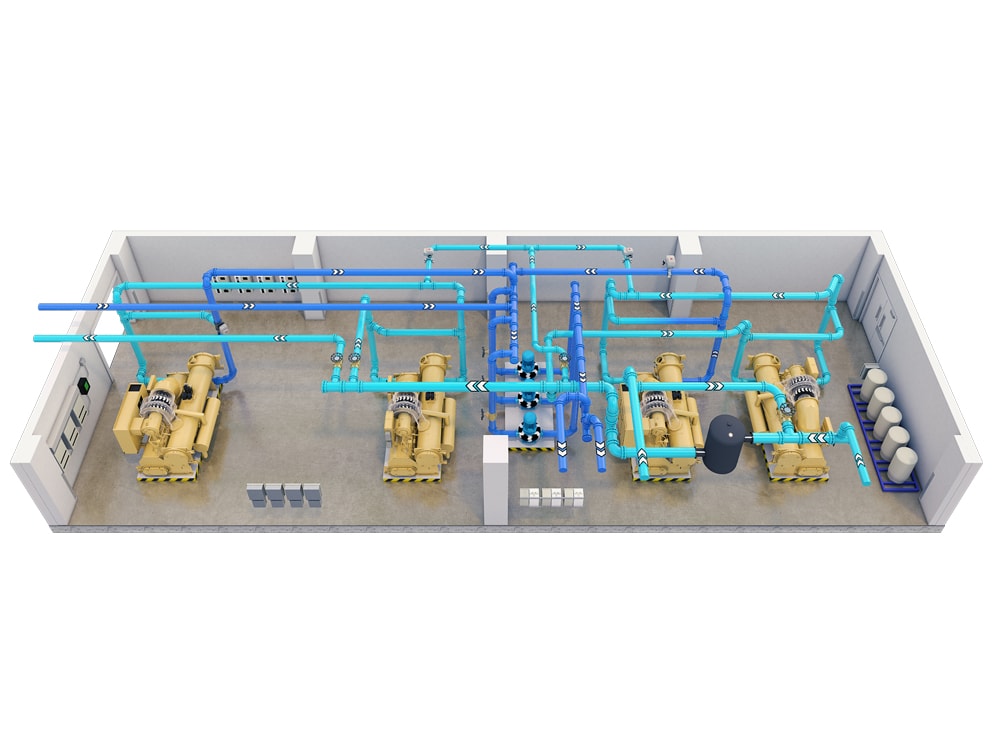

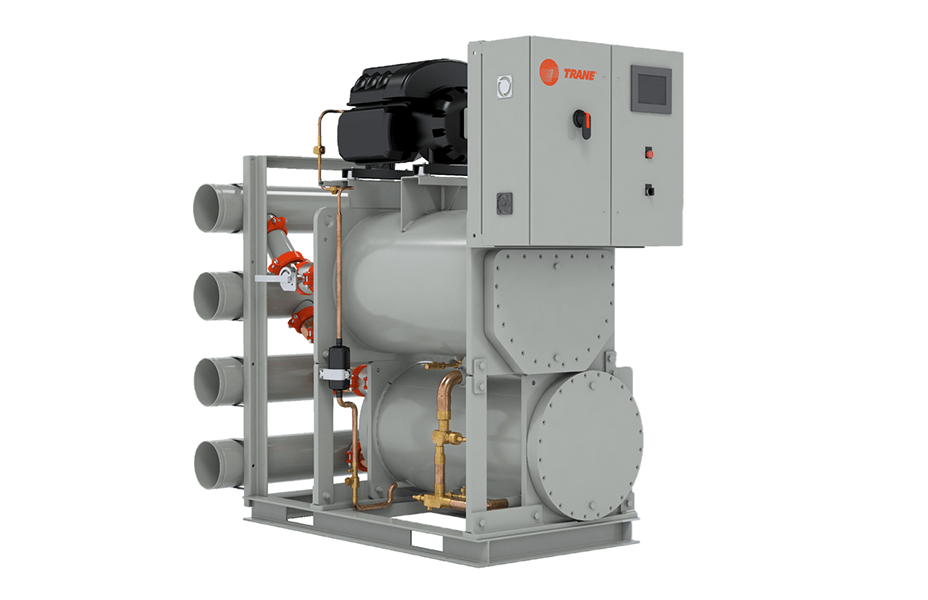

Centralizing mechanical operations

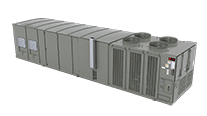

Four mechanical plants, located in three buildings, were centralized into one plant, with aging chillers and boilers replaced with more reliable, efficient equipment. The central plant includes a 1490-ton and four 1650-ton Trane® CenTraVac™ centrifugal chillers with variable frequency drive (VFD) to meet 6000-ton peak load requirements. Condensing boilers provide 30 million Btu to heat the complex and help with humidification issues. With a 20+ year life expectancy, the central plant will serve the facility’s long-term needs.

Reducing energy costs, improving aesthetics

More than 50,000 interior and exterior metal halide, mercury vapor and T-12 fluorescent lighting fixtures were replaced with high efficiency LEDs. The new fixtures offer 500 percent longer life, improve illumination and color rendering, enhance visitors’ experience, provide significant energy savings and reduce maintenance. More than 200 data loggers were deployed to measure run hours before and after the retrofit.

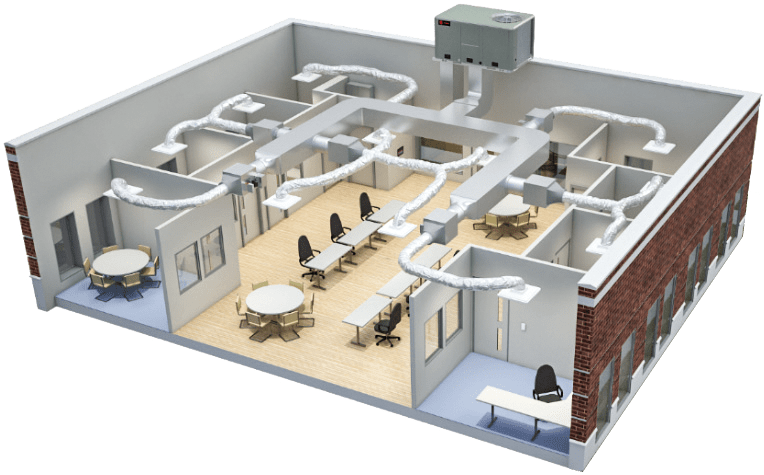

Controlling operations, managing energy use

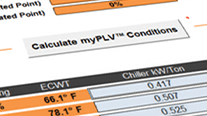

Using a Trane® Tracer™ SC building automation system (BAS), the GWCCA facilities team accesses building systems remotely from any web-connected mobile device to monitor operations, control set points, establish scheduling, and manage alarms. "With the Tracer, they monitor my secondary pumps, primary pumps, chillers, condensing water and all my flows,” said Wayne Rosser, physical plant manager, GWCCA. "The BAS makes sure I am running a very efficient plant."

Trane Intelligent Services measures the facility’s energy consumption, identifies anomalies, and anticipates problems, allowing GWCCA to modify systems if needed. The energy management systems also provide data in an easy to read format for metrics reporting. “Trane Building Performance allows us to check real-time operational data; provides 24/7/365 days of trending; and helps create dashboards to easily monitor usage, weather and occupancy levels," said Oden. "Based on this data, we can make intelligent decisions to determine budgeting.”

Results

Under a Georgia Energy Savings Performance Contract, Trane and GWCCA worked together to create a more efficient, sustainable and comfortable environment to improve the venue's competitiveness; enhance the visitor experience; and reduce energy costs and risk. Trane continues to work hand-in-hand with the customer, providing maintenance on central plant equipment and ongoing training for GWCCA staff to help ensure proper operation and maintenance of the systems. A Trane measurement and verification (M&V) team will visit the central plant twice a year to compare the cooling and heating performance during different occupancy levels and show types, and ensure that the energy savings is on track.

“We improved our lighting quality and HVAC system efficiency,” said Trefzer. “GWCCA is expected to achieve LEED® Gold certification and a big part of that is from the energy saving performance contract.”

“Trane worked around our events,” said Oden. “They were great partners and treated GWCCA as if it was their own.”