Summary

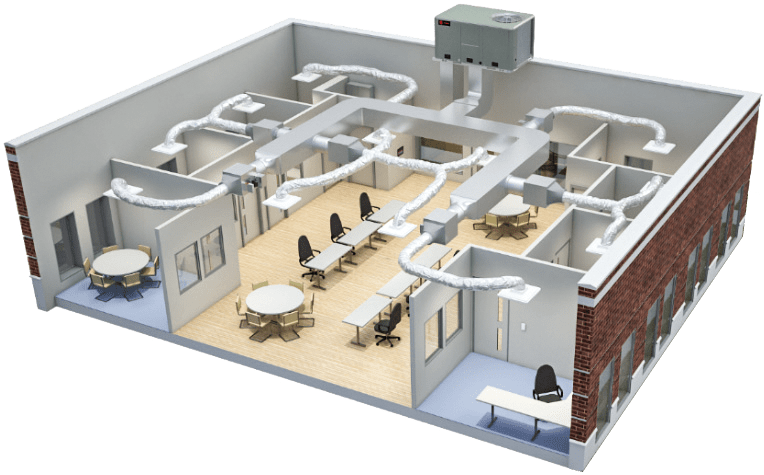

Two-thirds of the 600,000 square foot research-intensive Roger Guindon Hall is consumed with wet labs. The building houses the University of Ottawa’s Faculty of Medicine and Faculty of Health on an 80-acre Health Sciences Centre that also includes the Ottawa General Hospital, the Children’s Hospital of Eastern Ontario and the Royal Ottawa Regional Rehabilitation Center.

Challenge

Although the existing chiller, used to provide peak service for Roger Guindon Hall, was still reliable, regulations required that it be updated due to a phase out of the R-11 refrigerant used in the system. At the same time, the university sought to optimize its chiller plant to retain its capacity and reduce energy consumption. With Guindon Hall housing a major medical research facility, expectations were high that the upgrade would be completed without compromising research in progress at the facility.

Solution

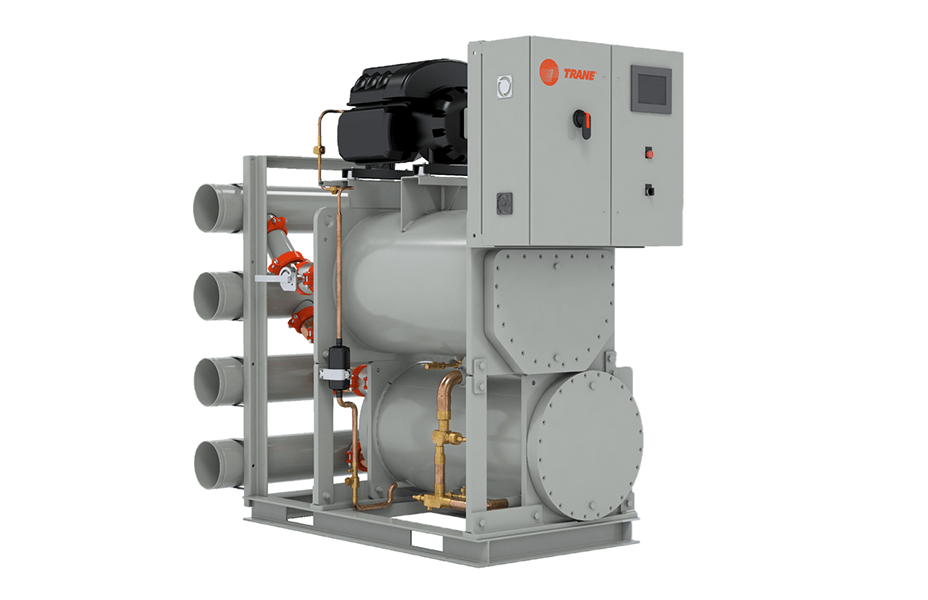

The university began by assembling a team to evaluate its options. It could renew the current system, convert it to a new refrigerant or entirely replace it. The evaluation process considered first costs, utility costs of the machine over a ten-year period, and delivery timing. Balancing the three criteria equally, it was determined that the Trane CenTraVac™ EarthWise™ centrifugal chiller was the lowest cost, the most efficient and the quickest ship of the options evaluated.

Maximizing energy savings

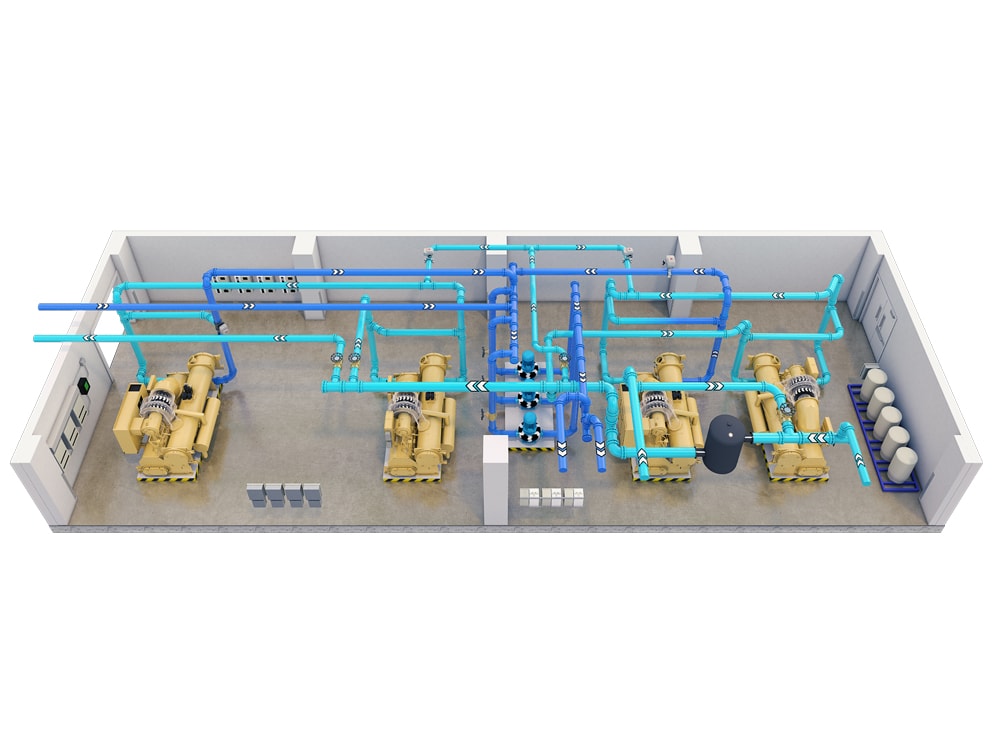

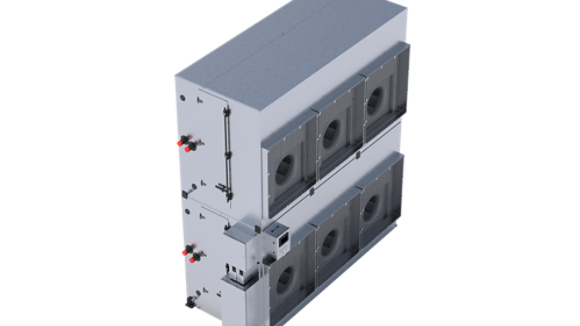

The older R-11 chiller was replaced with a new 1000-ton Trane CenTraVac chiller. The highly efficient, robustly designed chiller provides the most reliable performance in the industry. The chiller’s variable speed drive continually monitors motor speed and load to maximize energy savings. Two heat recovery chillers work with the new CenTraVac chiller to satisfy comfort needs. The 750-ton cooling-only chiller was replaced in 1999 with a Trane 540-ton heat recovery chiller to meet winter cooling and heating demands. In addition, the building’s 950-ton heat recovery chiller, also by Trane, was converted to cooling-only operation.

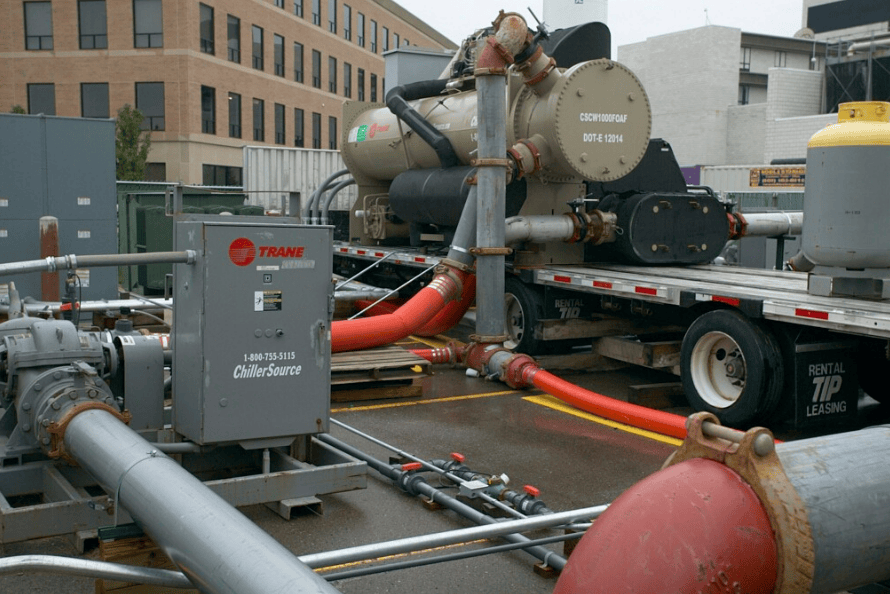

Handling an awkward installation

Trane technicians, in conjunction with Thompson Boiler Works, handled the awkward job of removing and replacing the large chiller through a hatch in the roof. The old CenTraVac chiller was lifted by crane through the opening and the next day the new CenTraVac was delivered in pieces and put in place. Trane technicians assembled the chiller pieces, and connected and charged the equipment.

Optimizing system operations

Different modes of operation, the new Trane CenTraVac and two previously installed Trane heat recovery chillers performing different functions, and variable pumping throughout the building and its towers, required a complicated sequence of operations. Trane and the university worked through twenty pages of critical sequencing to optimize efficiency, and after just four weeks, the system was up and running.

Results

Trane solutions have helped Ottawa University’s Roger Guindon Hall improve its HVAC operations and save significant energy costs. The university is saving $166,500 per year in cooling energy costs and another $120,000 per year in heating energy costs compared to base year. Replacing the 750-ton CFC chiller with a new 540-ton R-123 chiller correctly sized for the building, and modifying the existing 950-ton chiller to better match system requirements, produced 950,000 kWh in annual energy savings. Energy efficiency improved from 0.95 to 0.69 kW per ton at full load and even better at partial load. A variable speed chiller plant pumping system added another 750,000 kWh in annual energy savings.

The new variable speed drive CenTraVac chiller will reduce the building’s peak from 3000 to 2500. As a result of the peak reduction, the university received an incentive of $275,000 from the OPA (Ontario Power Authority).

The university is also realizing a $45,000 maintenance cost avoidance, and a savings equal to 333,000 kg of carbon dioxide emissions avoidance.

Pierre DeGagné, assistant director engineering and campus sustainability, commented, "The new CenTraVac compared to the old chiller uses about half the energy. It is going to reduce the building peak by 500 kilowatts, a significant drop!

“We chose Trane because they provided the best total cost of ownership. We are always looking to optimize total cost of ownership because we plan to be in business for a long time.

"We have a close relationship with the people at Trane, from their engineers to their field technicians. We look for business partners who are honest and operate with integrity, have the capabilities to get the job done and give us value for our money.

“The users of the facility never knew we were changing out the chiller. That’s a credit to the whole team. We bought it, we installed it and we started it on time. Everything went without a glitch. That makes me feel really good.”

About University of Ottawa

Roger Guindon Hall, an important medical research facility located in the heart of the University of Ottawa campus, uses nearly 25 percent of the university’s electricity consumption. The new Trane CenTraVac chiller, installed in Guindon Hall, works with two previously installed Trane CenTraVac chillers to satisfy the comfort needs of students and staff.