Challenge

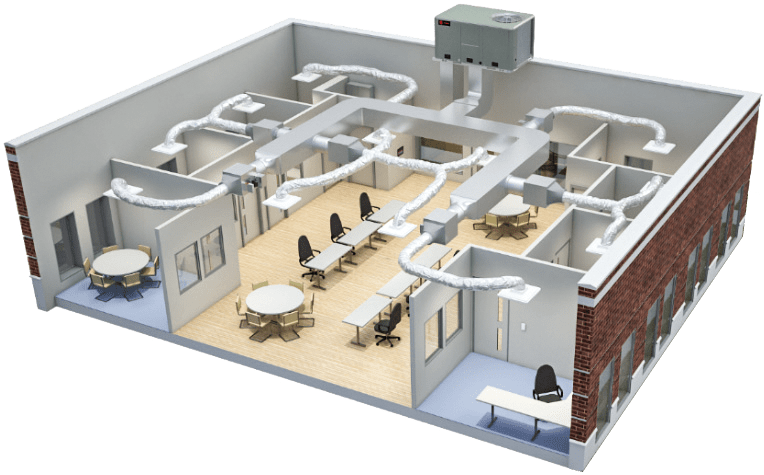

The forty-year-old, two-tower Sun Life Financial Center was operating two connected cooling systems. When Bentall Kennedy identified the need for end-of-life equipment replacement in one of the building's cooling plants, they decided to evaluate the equipment in both towers, seeking to improve efficiency throughout the complex and align with the firm's commitment to sustainability.

Solution

Working with Halsall, Alliance Engineering and Bentall Kennedy conducted an in-depth design/costing study, using a calibrated building simulation model to evaluate several upgrade scenarios compared to a simple like-for-like replacement. Comparison metrics included energy performance, return on investment and greenhouse gas impact. The study revealed that upgrading the Sun Life Financial Center with a replacement heat recovery chiller, along with a second upsized chiller to replace the two existing units, would provide a positive net present value, operational redundancy and fuel switching capabilities.

Life cycle cost analysis and performance evaluation

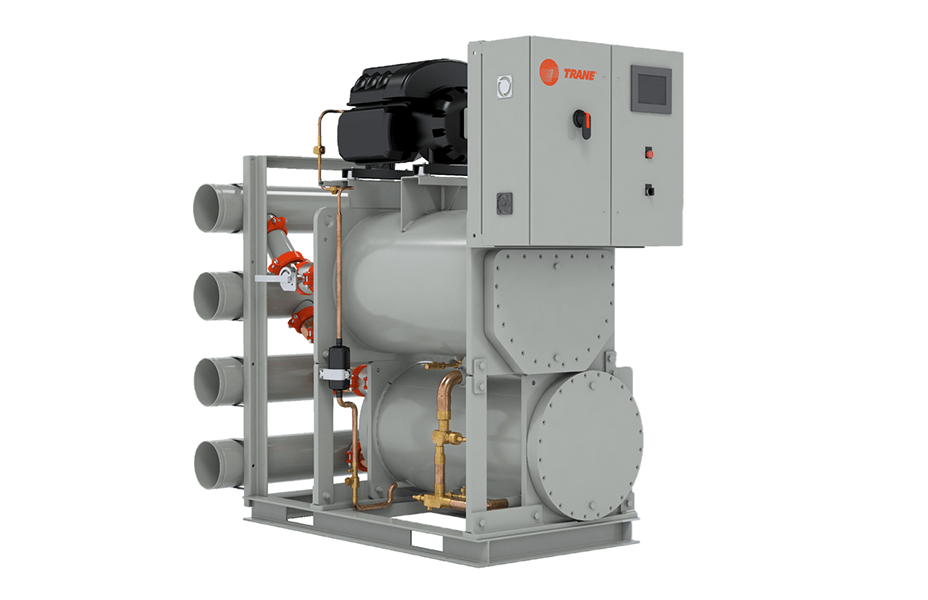

Alliance and Bentall Kennedy understood the advantages of pre-selecting the equipment separately from the installation tender to ensure they got exactly what they needed to meet efficiency objectives. Equipment performance was evaluated at part- and full-load conditions to model the diverse tenant needs. Based on a twenty-year life cycle cost analysis that included installed and operating energy costs; a ten-year parts, labor and refrigerant warranty; service agreement; factory performance evaluation; and potential energy incentives, Bentall Kennedy selected Trane equipment for the project.

Reliable operation and efficiency

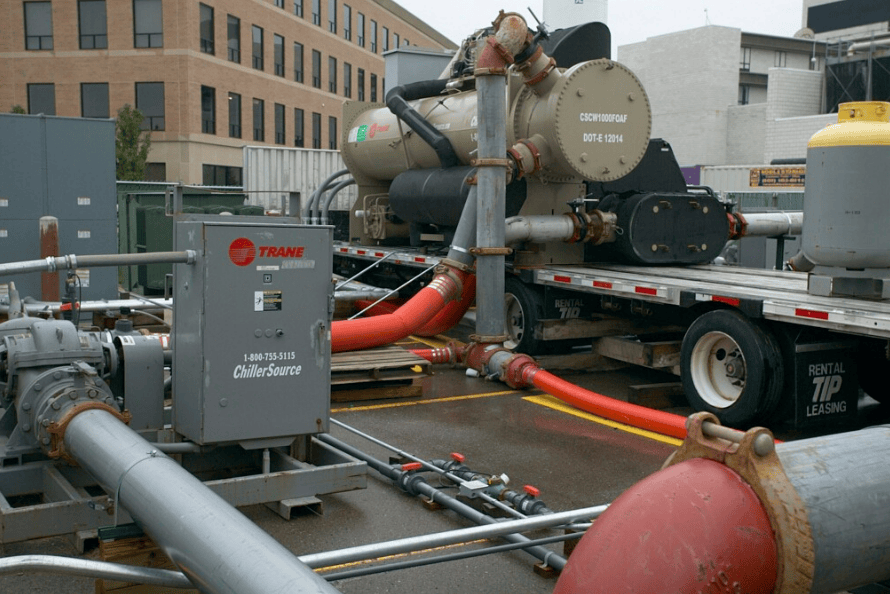

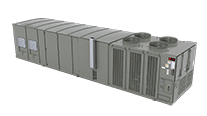

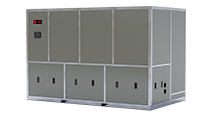

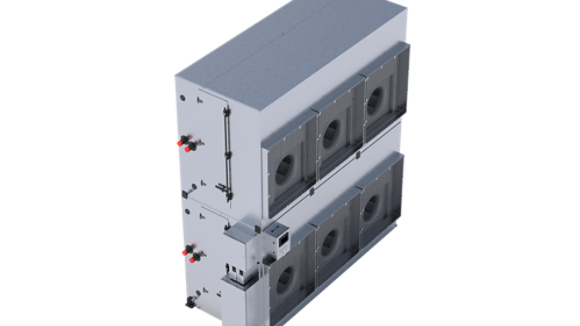

Following a competitive tendering process, Bentall Kennedy engaged Alliance to proceed with the installation of the upgrade, replacing its aging equipment with Trane® CenTraVac™ centrifugal chillers. With the fewest moving parts in the industry, CenTraVac chillers provide reliable operation and tight temperature tolerances, and can achieve average full-load efficiency levels 15 percent better than competitive chillers. The use of low-pressure refrigerant and reduced refrigerant leak rates help to reduce greenhouse gas emissions.

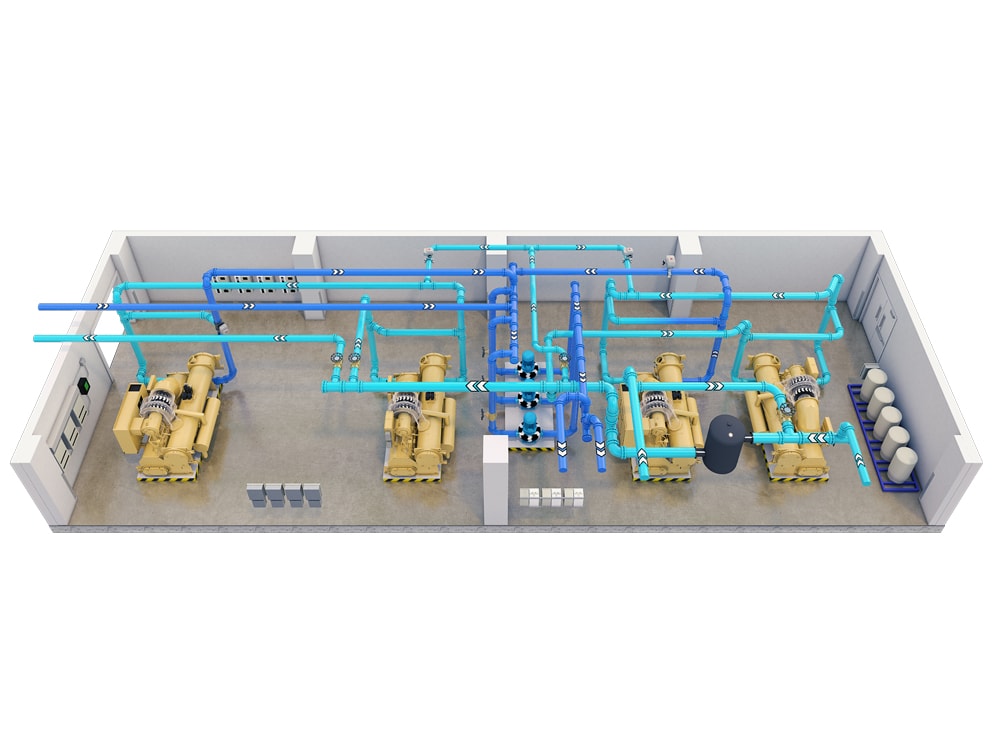

An enhanced energy management strategy

To better respond to building needs, the chilled water pumping system was changed from a primary-secondary system to variable-primary flow, eliminating three 60 hp chilled water pumps, lowering capital and maintenance costs, and providing greater system reliability. Heat recovery included on the first chiller makes use of heat normally rejected into the air to further improve operating efficiency and reduce energy costs. An Adaptive Frequency™ Drive (AFD₃) on the second chiller varies the speed of compressor motors to optimize performance, reducing energy consumption and electrical demand charges. The AFD₃ offers a part-load efficiency improvement of more than 40 percent compared to previous constant-speed chiller designs. The chiller also includes free cooling, a refrigerant migration feature that can provide up to 45 percent of chiller capacity without running the compressor.

Results

Demonstrating the value of planning, in-depth study, and energy modeling, Bentall Kennedy, working with Alliance Engineering, Halsall and Trane, improved energy performance of the Sun Life Financial Center. A life cycle cost analysis was used to aid in equipment selection for a variable-primary flow system that uses Trane CenTraVac chillers with heat recovery, AFD₃, and a free cooling option. As a result, the building has increased redundancy, reduced operating costs, and lowered greenhouse gas emissions by 2.5 percent. The high performance of the system earned an energy efficiency incentive of more than $536,000 from the Ontario saveONenergyOM conservation program.

“The equipment performance was first class at both full- and part-load,” said Brandon Malleck, Manager, Technical Services and Projects, Bentall Kennedy. “We are pleased with the carbon reductions, energy savings, and best-in-class support provided by Trane."